Multifunctional material loading trestle bridge of waste-incineration power plant

A waste incineration and power plant technology, applied in bridges, bridge applications, storage devices, etc., can solve the problems of easy leakage of landfill leachate, many garbage transportation vehicles, and large garbage transportation volume, etc., to improve the efficiency of garbage transportation, design Reasonable and improve the effect of transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

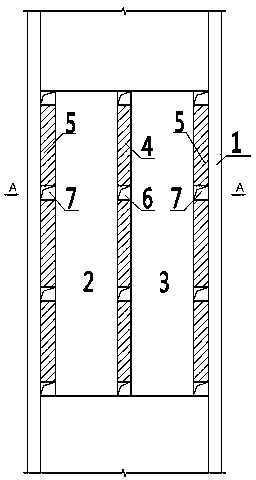

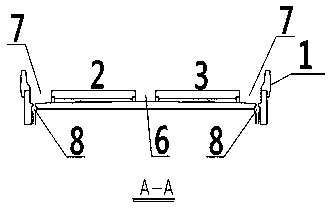

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] see Attachment.

[0012] A multifunctional feeding trestle for a waste incineration power plant, comprising a feeding trestle 1, a first truck scale 2 and a second truck scale 3, a foundation pit is set on the flat slope section of the feeding trestle 1, the first truck scale 2 and the second truck scale 3 The second truck scale 3 is arranged in the foundation pit along the longitudinal direction of the feeding trestle 1, the first truck scale 2 and the second truck scale 3 are parallel to each other, and the upper surfaces of the first truck scale 2 and the second truck scale 3 are connected to the feeding trestle 1 bridge. The surfaces are at the same level, which is convenient for the garbage truck to drive smoothly to the truck scale for weighing; according to the garbage transportation volume and the layout of the roads in the factory, the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com