Method and system for vacuum generation

A vacuum and vacuum container technology, applied in the charging system, pump/compressor arrangement, electrical control, etc., can solve the problem of not being able to use the ejector to completely vacuum and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

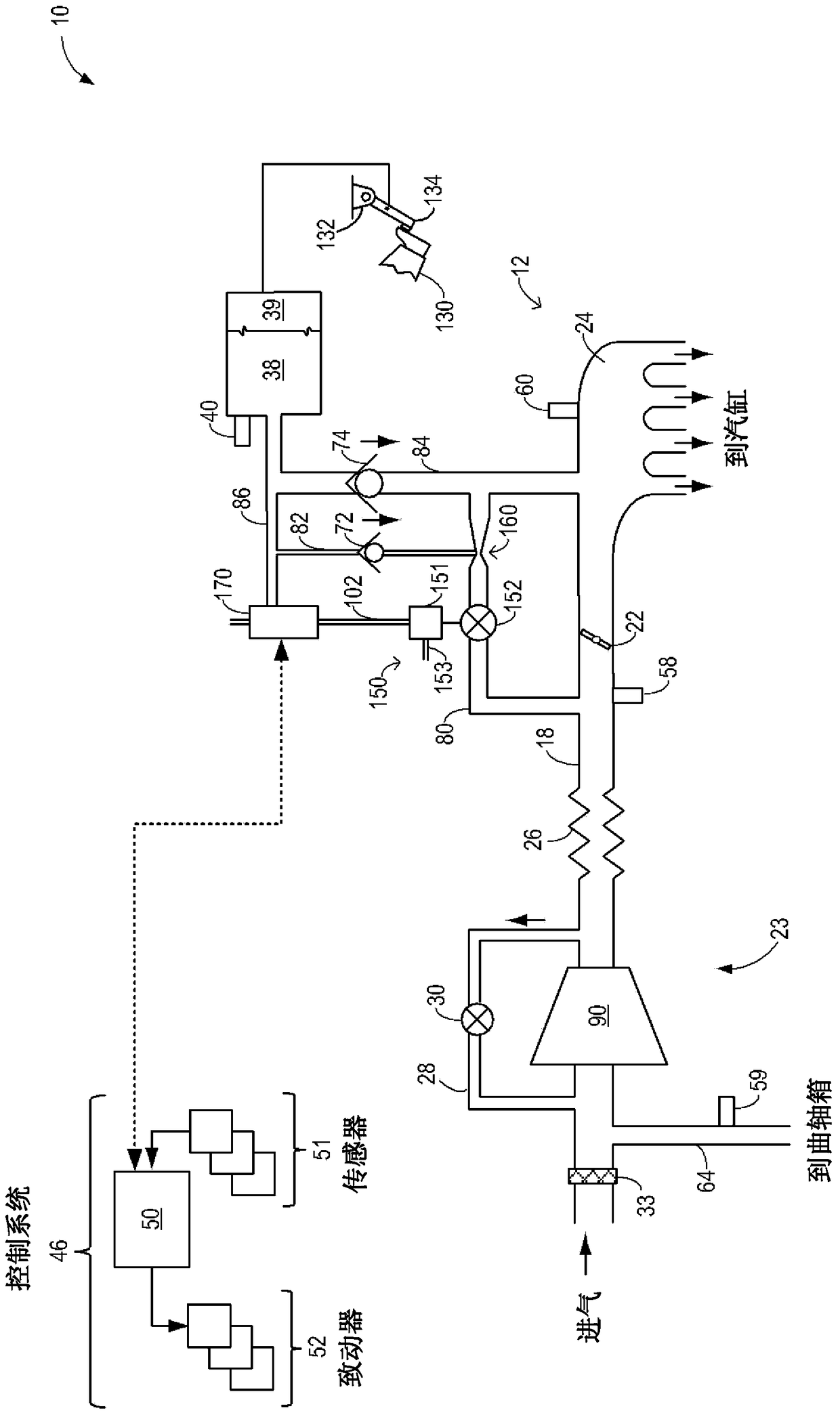

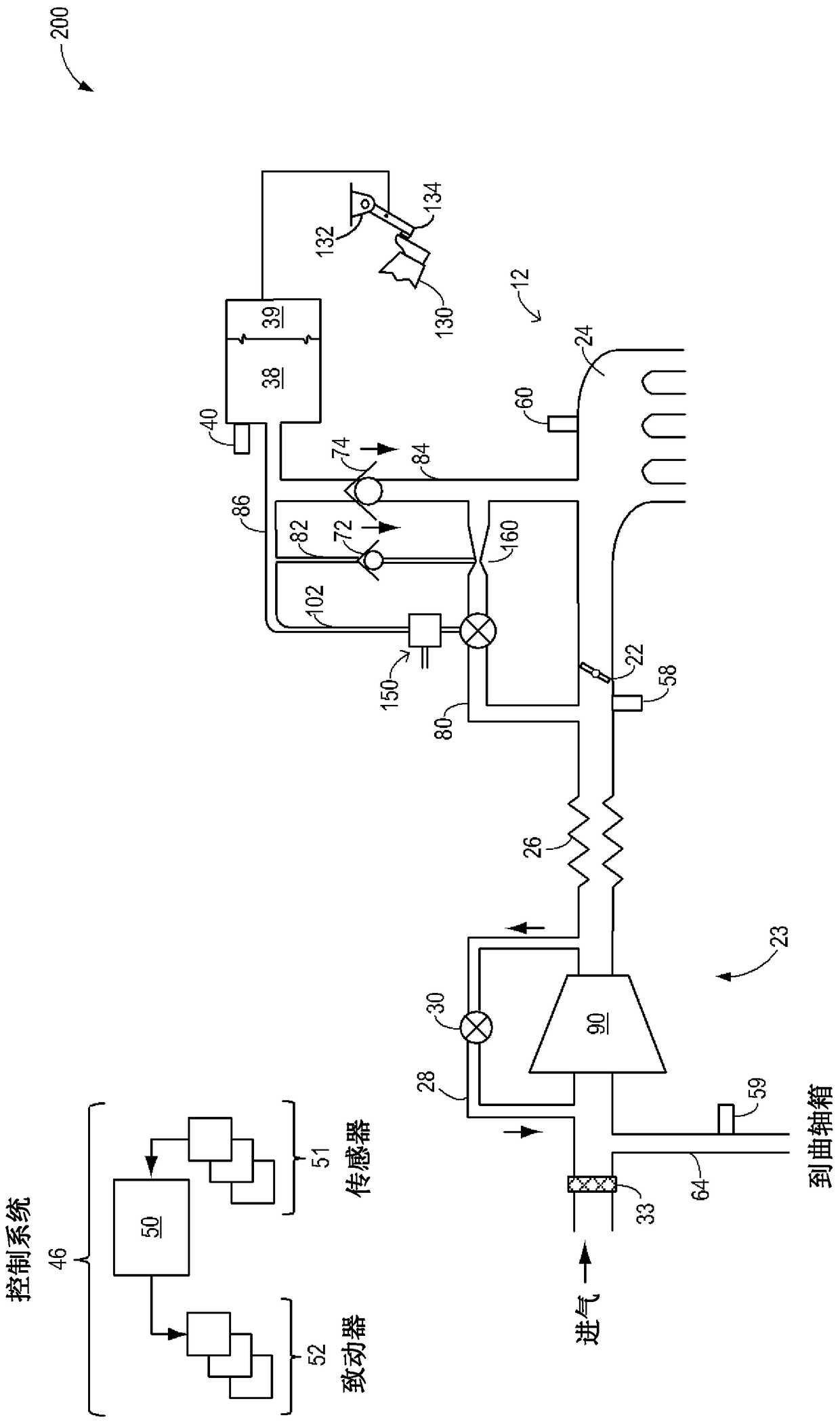

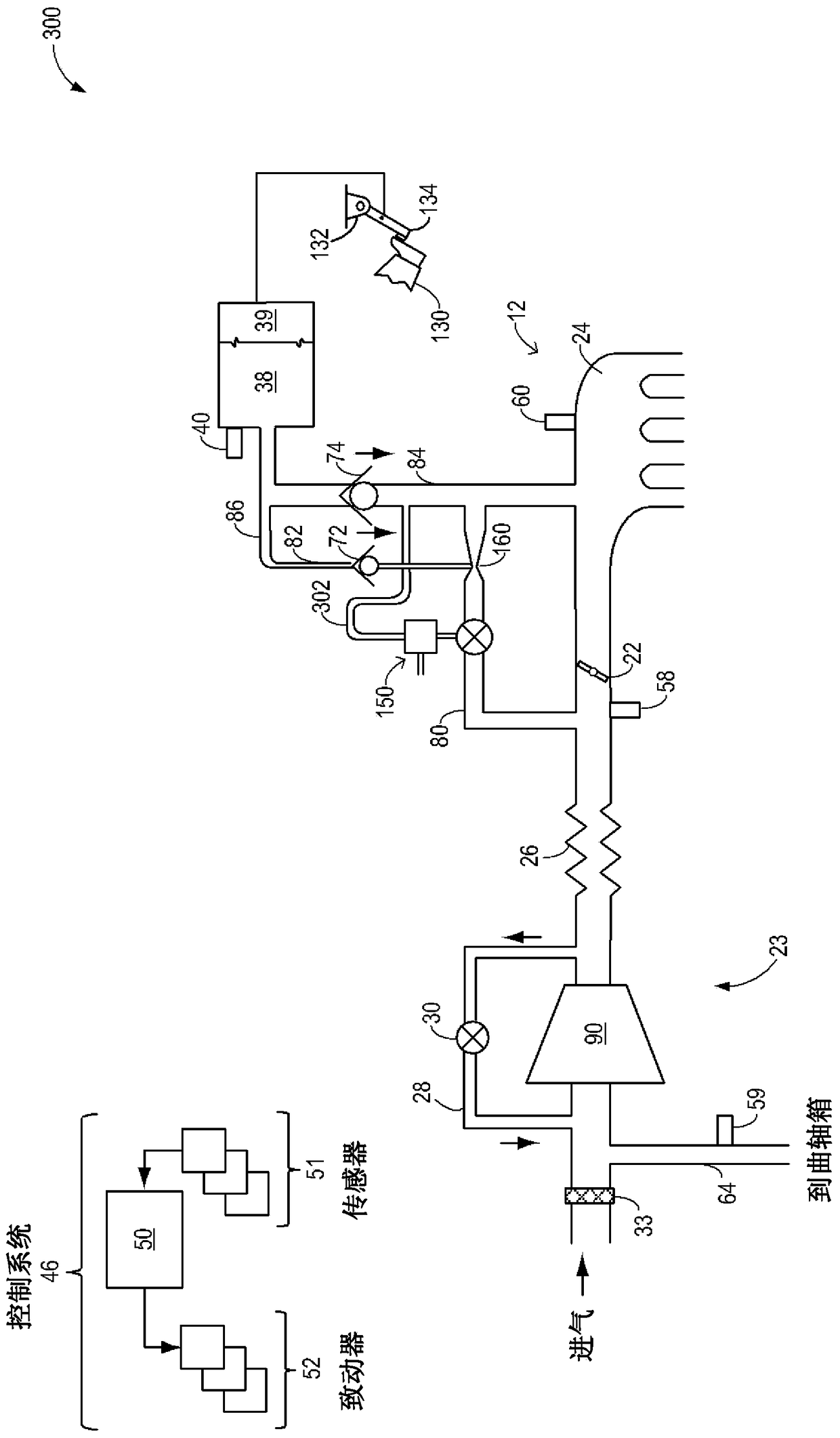

[0018] The present invention provides for low-cost control by being coupled to an engine system such as Figure 1-5 and Figure 7 Method and system for power flow of an injector for an engine system. Motive flow valves can be coupled to injectors such as Figure 1-5 shown in . The valve may be pneumatically controlled and vacuum actuated so that motive flow through the valved injector can be appropriately increased or decreased ( Figure 6 ). In some embodiments, such as Figure 7 As shown in , a vacuum-actuated throttle can be used to control power flow through the injector. By coupling a vacuum actuated valve (or throttle) to a vacuum reservoir of the engine system, the valve can be actuated to open or close based on vacuum replenishment requirements. The controller can be configured to execute control programs such as Figure 8 example program) so that the valve opens to increase motive flow (and vacuum generation) at the ejector when vacuum availability at the vesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com