Display substrate and manufacturing method thereof, display panel and display device

A technology for displaying substrates and manufacturing methods, applied in instruments, nonlinear optics, optics, etc., can solve problems such as narrow borders, reduce possibilities, increase production costs, and achieve the effect of narrow border design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

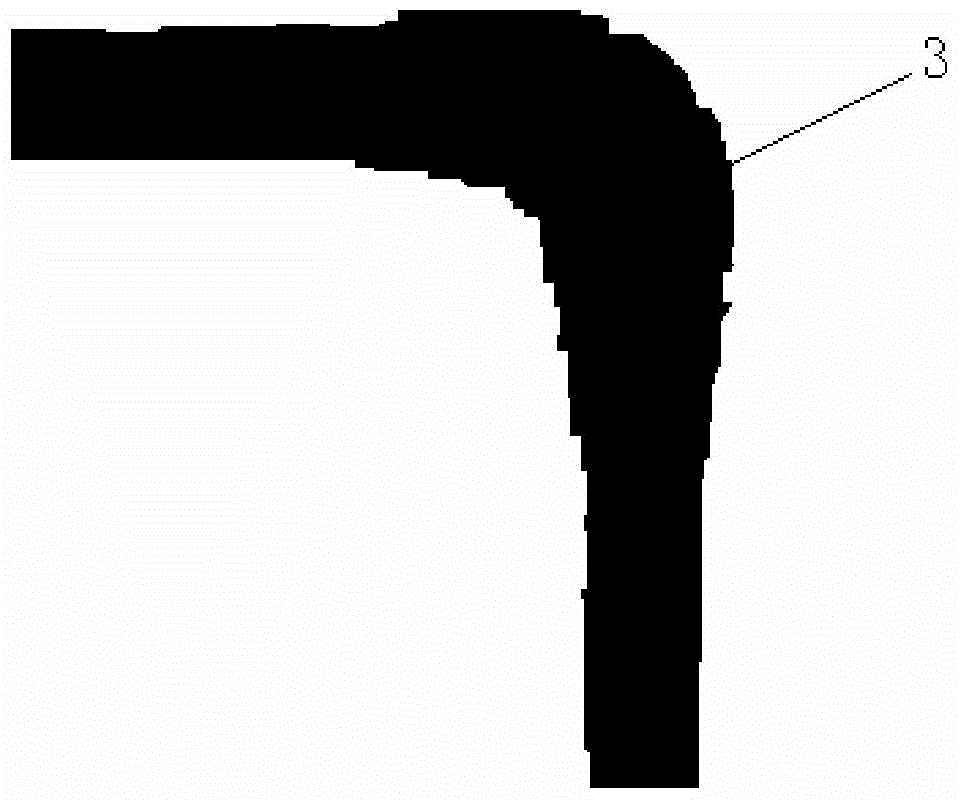

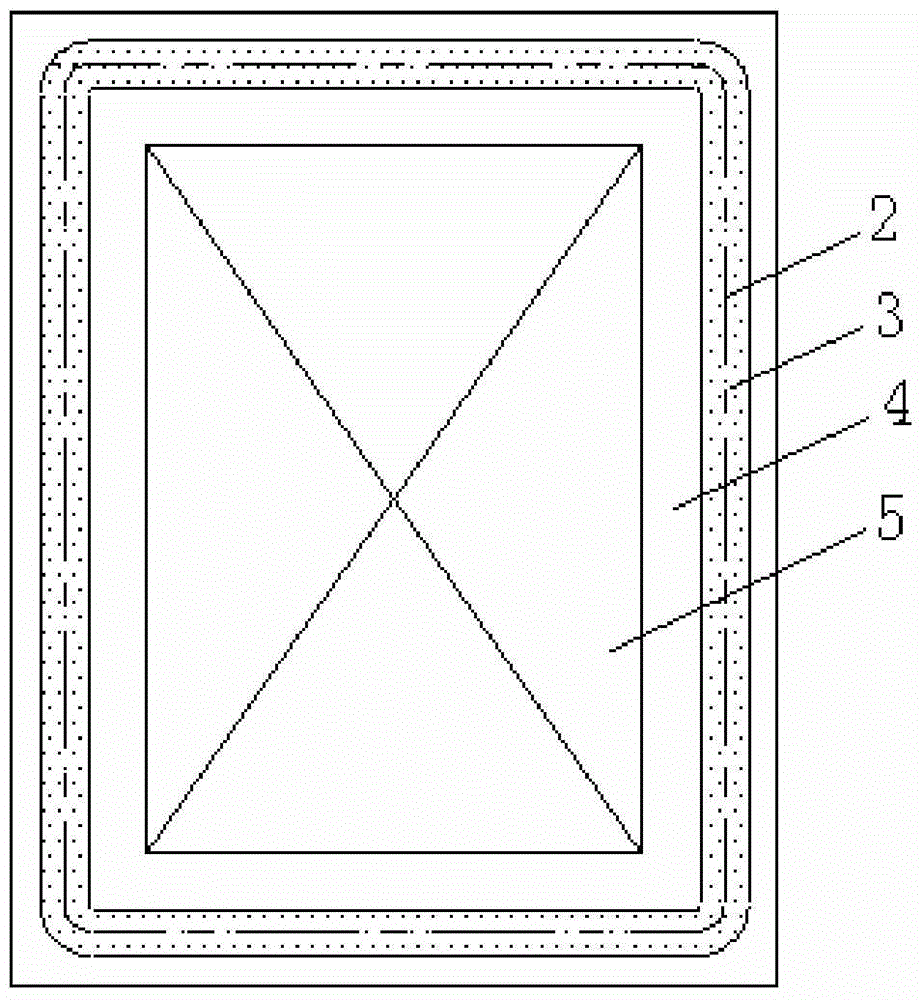

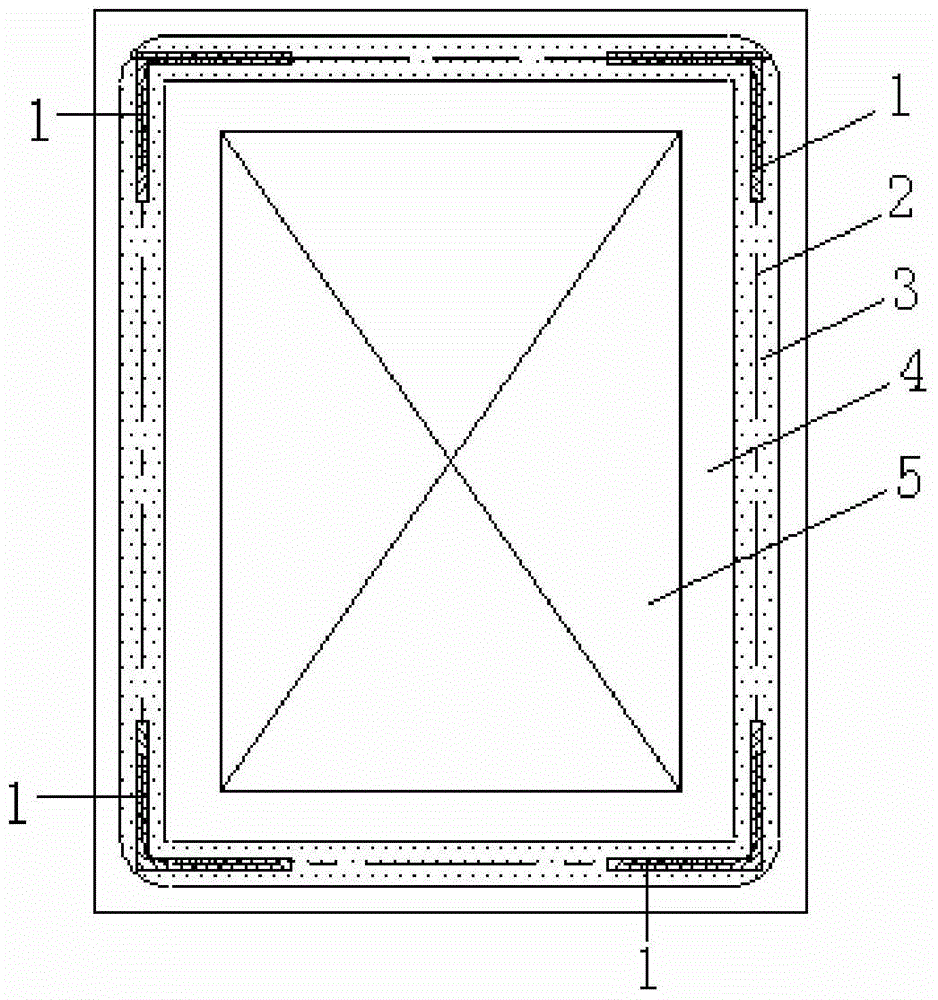

[0036] This embodiment provides a display substrate, which can be an array substrate or a color filter substrate, and can be used to make a display panel, such as a liquid crystal display panel. , it is necessary to coat the sealant on the display substrate, all of which can be applied to the display substrate of the embodiment of the present invention. Such as Figures 3 to 5 As shown, the display substrate of this embodiment includes a substrate, which can be a glass or quartz substrate, and the substrate includes a display area 5 and a non-display area 4 (for arranging lead joints, etc.) located around the display area 5, wherein the display area 5 There are various pixel structures for displaying in the center, and the non-display area 4 is arranged around the display area 5 for arranging lead joints, coating sealant, and the like. In the non-display area 4, there is a frame sealant coating area 2, which is used to coat the frame sealant to realize the box alignment of th...

Embodiment 2

[0070] This embodiment provides a display panel, which includes a first substrate, and the display panel further includes the display substrate in Embodiment 1.

[0071] Preferably, the first substrate is an array substrate, and the display substrate is a color filter substrate; or the first substrate is a color filter substrate, and the display substrate is an array substrate.

[0072] This embodiment also provides a manufacturing method for the above-mentioned display panel (taking the display panel as an example of a liquid crystal display panel), including the following steps:

[0073] Such as Figures 3 to 5 As shown, the frame sealant 3 is coated on the frame sealant coating area 2 of the display substrate (that is, the color filter substrate) in Example 1, wherein the frame sealant 3 is formed above at least part of the raised structure 1;

[0074] Drop liquid crystal into the display area of the first substrate (at this time, the array substrate);

[0075] Carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com