An automatic coconut cutting machine

A cutting machine and automatic technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of dangerous operation, difficulty in meeting food hygiene requirements, pollution of coconut juice and coconut meat, etc., so as to save labor and meet food hygiene requirements , the effect of reducing disability accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

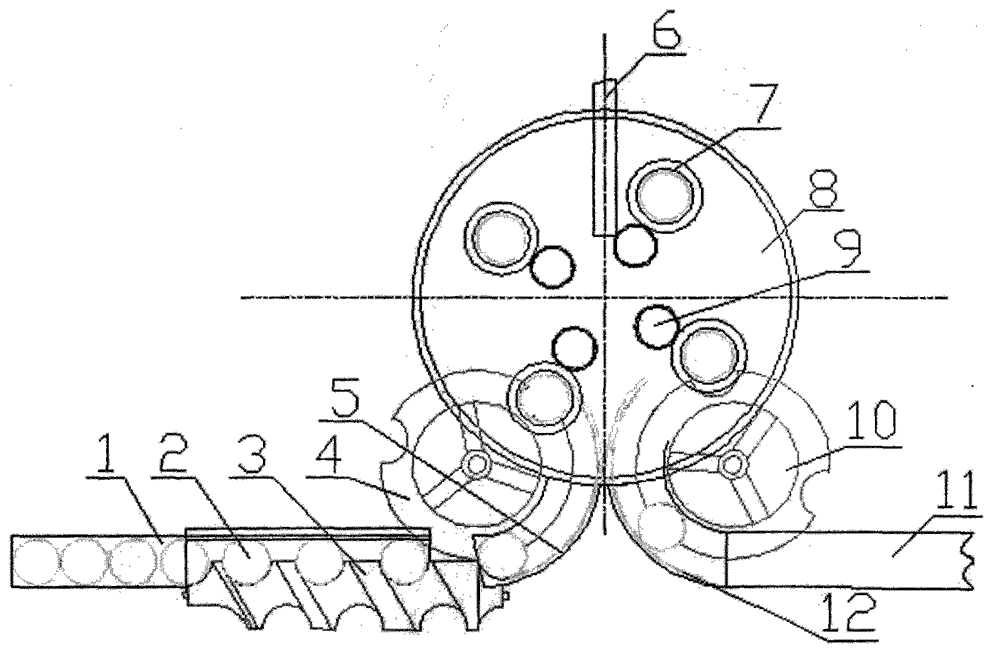

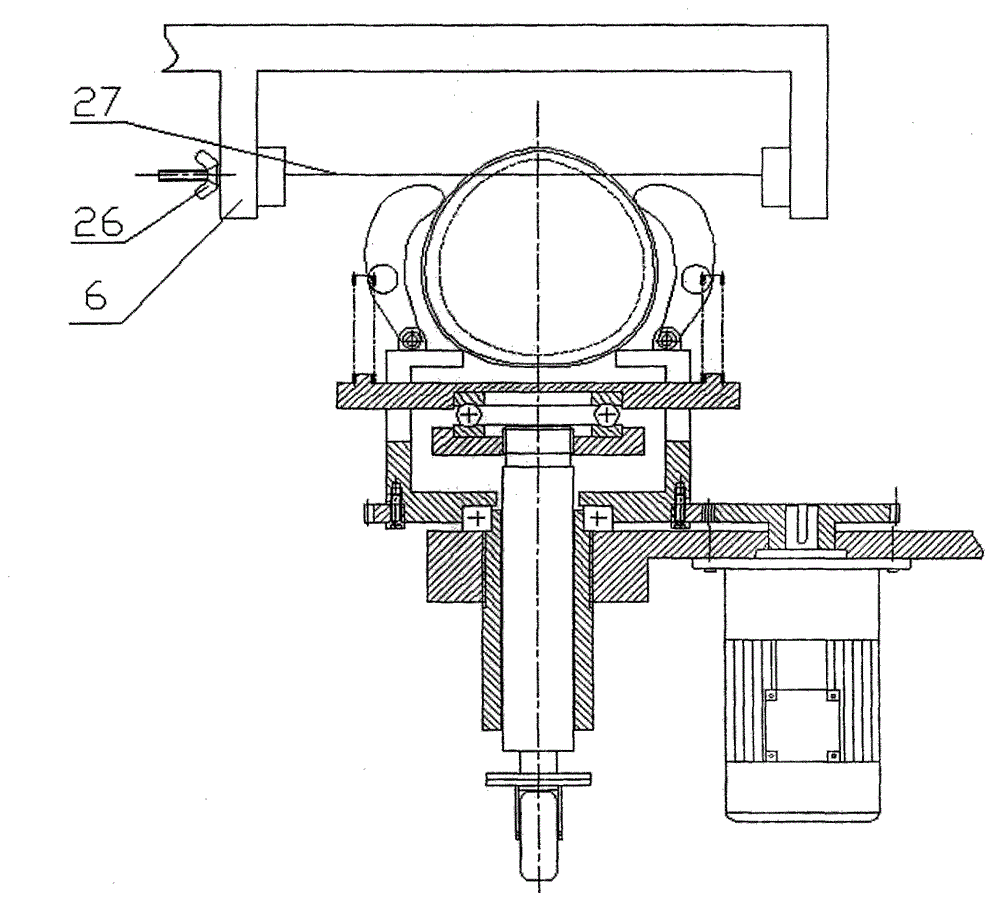

[0018] There is an inlet conveyor chain 1, one side of the inlet conveyor chain 1 is provided with a variable pitch screw 3, behind the variable pitch screw 3 there is an inlet star wheel 4, the inlet star wheel 4 is connected with the automatic cutting machine, the automatic cutting machine The exit is provided with an exit star wheel 10, and the exit star wheel 10 is connected with the output chain path 11. One side of automatic cutting machine is provided with wire saw fixed mount 6, and wire saw is housed on the wire saw fixed mount 6, and automatic cutting machine is also provided with station pallet 7.

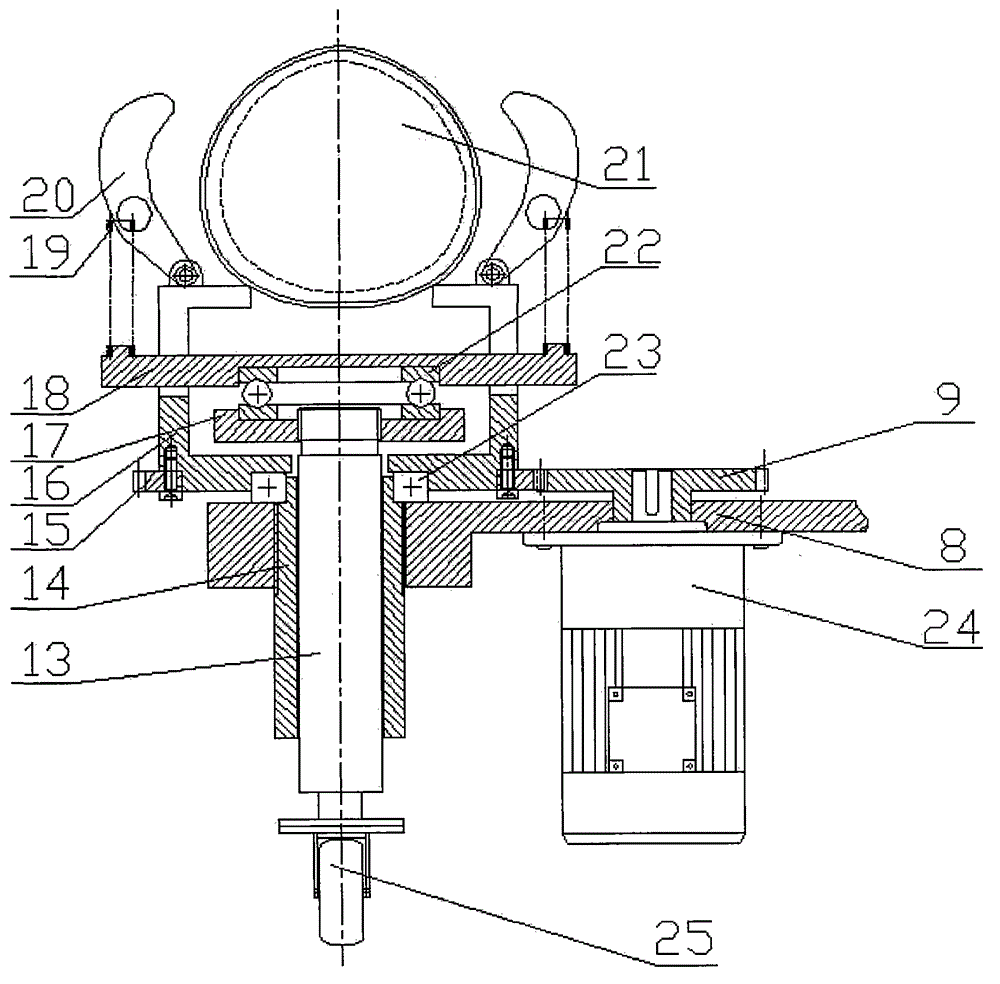

[0019] Described station tray 7 is made up of coconut tray 16, upper tray 18, lower tray 17 and mechanical finger 20, and mechanical finger 20 links to each other with coconut tray 16 by hinge, and upper tray 18 links to each other with mechanical finger 20 by spring 19, and upper tray 18 A thrust bearing 22 is provided between the lower tray 17 .

[0020] Described coc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com