Mounting and cutting process for shaped raw stone, angle-adjustable special charging platform and cutting machine

A cutting machine and stone technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low efficiency, a lot of waste, and the inability to unify one machine for dual use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

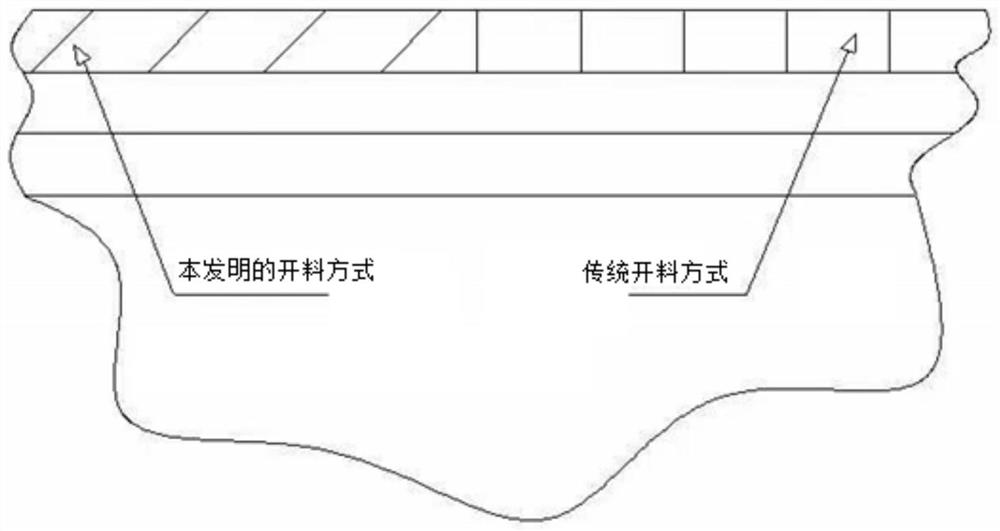

[0045] Embodiment 1: a kind of loading and cutting process of shaped raw stone 7, as Figure 1-5 as shown,

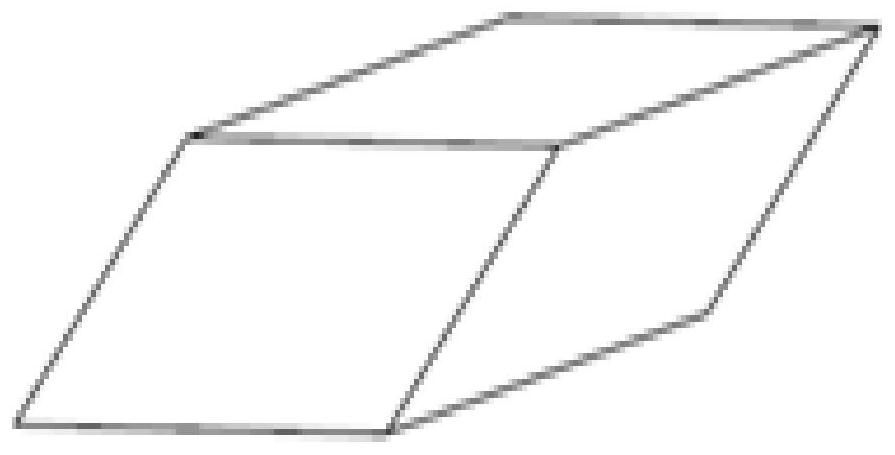

[0046] Step S1, cutting diagonally along the length direction from the block to obtain several pieces of shaped raw stone 7 in the shape of a rhombus or a parallelogram;

[0047] Step S2, connecting the inclined bottom surface of the lower end of the shaped raw stone 7 with one or more pieces of auxiliary materials to form a whole, and then installing them on the material platform to cut the stone materials. During cutting, the shaped raw stone 7 is placed obliquely, so that the inclined plane to be cut at the beginning is maintained vertically, and then the cutting can be started. Such shaped raw stone 7 is used for corner stone cutting, and the waste is controlled at a minimum. The material body is inclined, and the two ends form a vertical plane, that is, the inclined plane is used as the plane of the cut corner stone, thereby greatly reducing the remaining waste ma...

Embodiment 2

[0050] Embodiment 2: special material platform, such as Figure 6 —8,

[0051] A material platform with adjustable stone angle is located directly below the bridge cutting machine, and the stone material is installed on the material platform. The material platform can adjust the inclination angle of the installed stone material and fix it at the adjusted angle for stone material cutting; the horizontal The cutting assembly 2 can adjust the included angle between the horizontal cutting tool and the horizontal plane. The obliquely placed stones are monolithic diamond-shaped or parallelogram-shaped raw stones whose bottom is connected with auxiliary materials; specifically: the stone angle-variable material table 1 includes: table top 11, stone support rotating seat set at the front end of the table 12. The bottom of the stone is installed on the stone support rotating seat, and the other end of the table is installed with one or more rows of telescopic roof devices installed al...

Embodiment 3

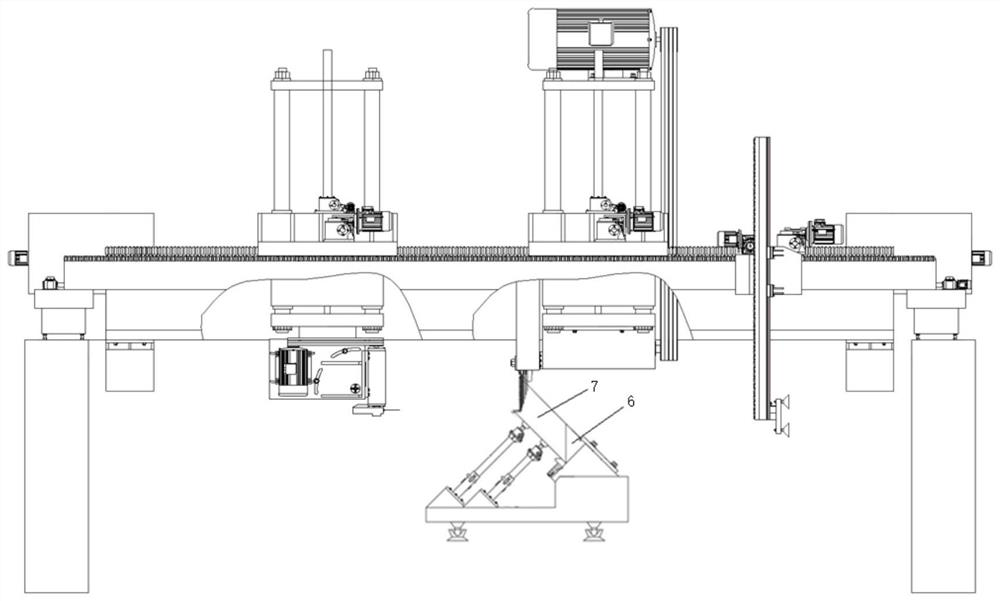

[0052] Embodiment 3: Bridge-type shifting and cutting, flat stone dual-purpose cutting device, such as Figure 6 —16,

[0053] A cutting machine for shaped raw stone, on the main beam 10 is installed a pair of vertical cutting assembly 3 and horizontal cutting assembly 2 that can be relatively independently moved horizontally and vertically, the main shaft end of the vertical cutting assembly 3 can be A replaceable vertical cutting assembly is installed in the way of disassembly, and the vertical cutting assembly is one of the cornerstone cutting assembly and the flat stone cutting assembly, each of which includes several flanges 103, partitions 105 and several pieces of size Different cutterheads 104, the cutterheads 104 are respectively installed and set on the end of the main shaft through a pair of flanges 103 and a partition 105; the material table is installed on the ground below the cutting machine in a removable manner; The platform can adjust the inclination angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com