A hollow capsule capable of controlling disintegration time limit and preparation method thereof

A technology of hollow capsules and disintegration time limit, which is applied in medical formula, medical preparations of non-active ingredients, drug delivery, etc., and can solve problems such as difficulty in determining the content of hollow capsules, uncontrollable disintegration time limit, and low pullulan , to avoid human absorption and metabolism problems, controllable disintegration time limit, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

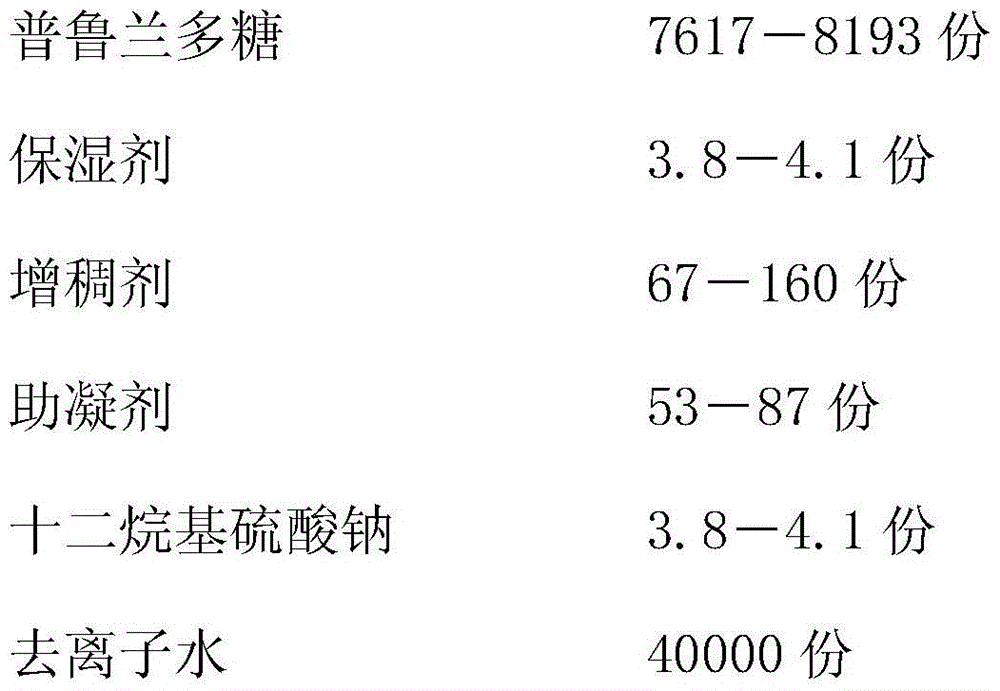

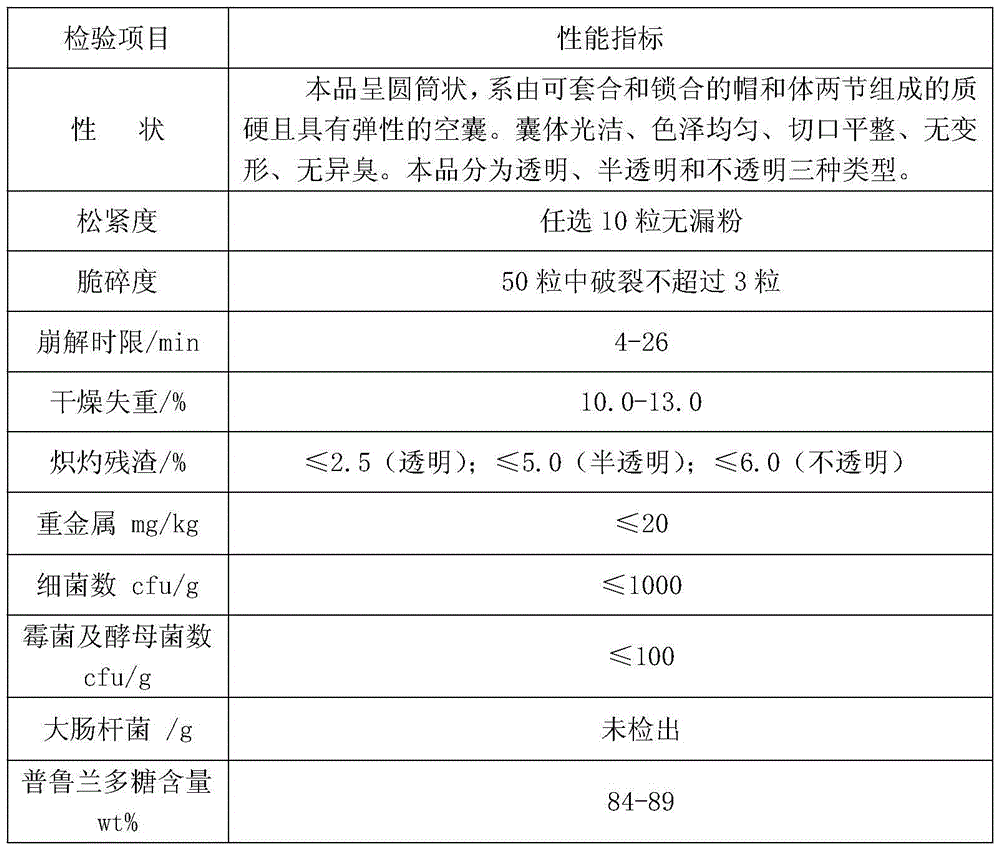

[0021] A method for preparing a hollow capsule capable of controlling the disintegration time limit, the preparation steps are as follows: First, 3.8 parts of glycerin, 67 parts of potassium chloride, 160 parts of carrageenan and 3.8 parts of sodium lauryl sulfate and stirred separately until uniformly dispersed, then added 38,500 parts by mass of deionized water at 80°C, stirred until the system was completely dissolved, and added 7617 parts of pullulan while stirring after the solution was clarified, Finally, the glue is fully stirred, the stirring speed is 50r / min, the stirring time is 30min, and the glue is kept at 70°C for 4h, and then at 55°C for 7h; finally, the glue is molded by dipping the mold into glue, Dry at 28°C for 120 minutes to obtain the rubber base, and then remove the mold, cut and fit the rubber base to obtain the hollow rubber. The water content of the hollow capsule is 10wt%, and the disintegration time limit of the hollow capsule is 26 minutes, the succ...

Embodiment 2

[0023] A method for preparing a hollow capsule capable of controlling the disintegration time limit, the preparation steps are as follows: First, 3.9 parts of polyethylene glycol, 80 parts of potassium chloride, and 67 parts of carrageenan are sequentially added to 1500 parts by mass of deionized water at room temperature and 3.9 parts of sodium lauryl sulfate and stirred until uniformly dispersed, then added 38500 parts by mass of deionized water at 90°C, stirred until the system was completely dissolved, and added 7904 parts of Purus while stirring after the solution was clarified. Finally, fully stir the glue solution with a stirring speed of 55r / min and a stirring time of 40min, and keep the glue solution at 70°C for 5h, then heat and defoam at 50°C for 8h; Plastic molding, drying at 27°C for 150 minutes to obtain the rubber base, and then demoulding, cutting and fitting the rubber base to obtain the hollow rubber. The water content of the hollow capsule was tested to be 12...

Embodiment 3

[0025] A method for preparing a hollow capsule capable of controlling the disintegration time limit, the preparation steps are as follows: First, 3.9 parts of glycerin, 53 parts of potassium chloride, 133 parts of carrageenan and 4.0 parts of sodium lauryl sulfate and stirred separately until uniformly dispersed, then added 38500 parts by mass of deionized water at 85°C, stirred until the system was completely dissolved, and added 7896 parts of pullulan while stirring after the solution was clarified, Finally, fully stir the glue solution with a stirring speed of 60r / min and a stirring time of 25min, and keep the glue solution at 75°C for 4 hours, then heat and defoam at 55°C for 6 hours; finally, the glue solution is formed by dipping the glue mold into glue, Dry at 29°C for 160 minutes to obtain the rubber base, and then remove the mold, cut and fit the rubber base to obtain the hollow rubber. The water content of the hollow capsule is 11wt%, and the disintegration time limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com