Filter panel for the treatment of liquids, especially for disc wastewater filter equipment

A technology of liquid treatment and filter plate, applied in the direction of mobile filter element filter, filter separation, chemical instrument and method, etc., can solve the problems of reducing processing speed, filter surface clogging, filtering effect and filtering performance obstacles, etc. Achieve long life, low maintenance requirements, and improved reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

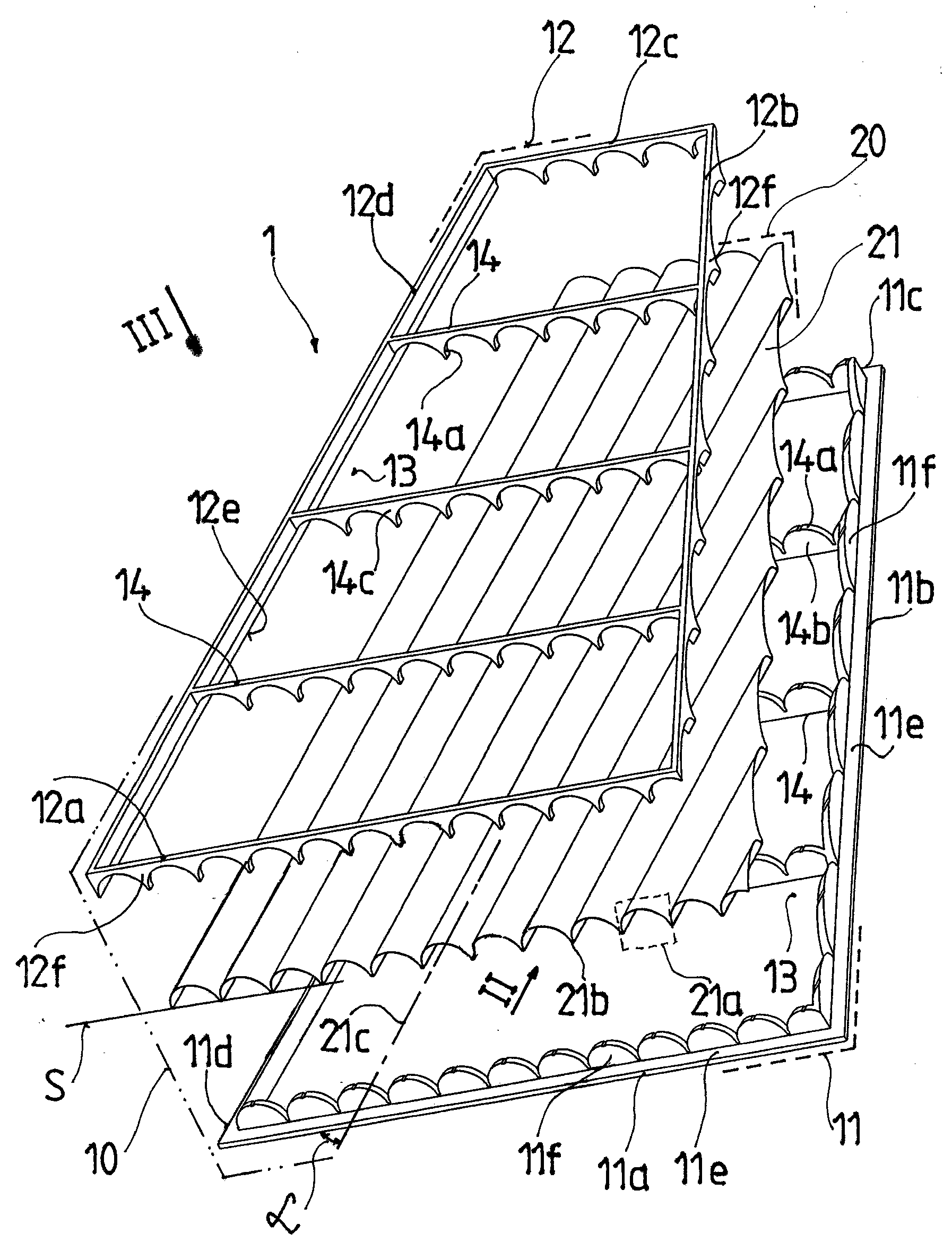

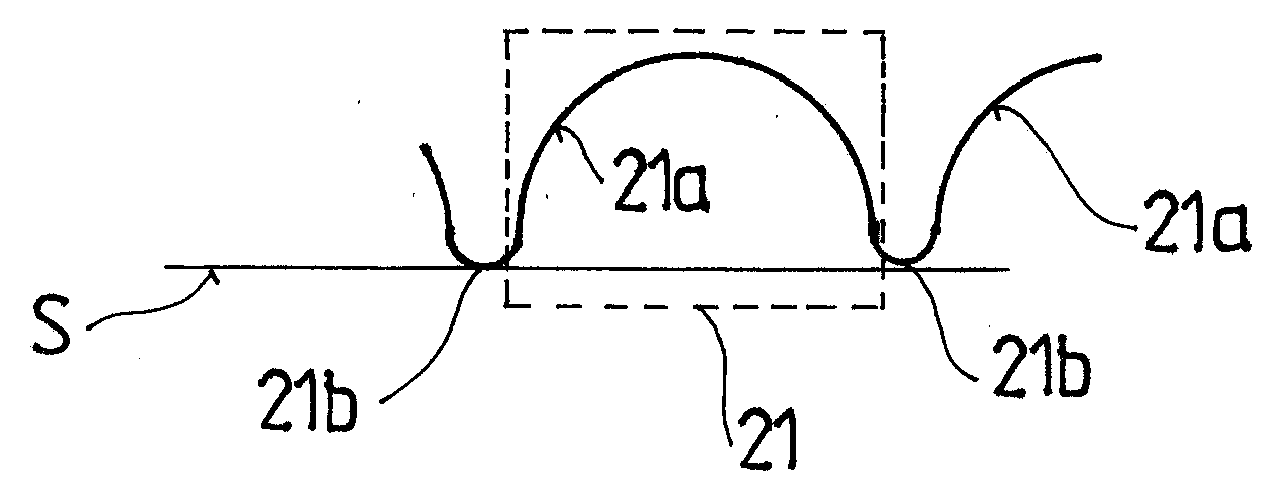

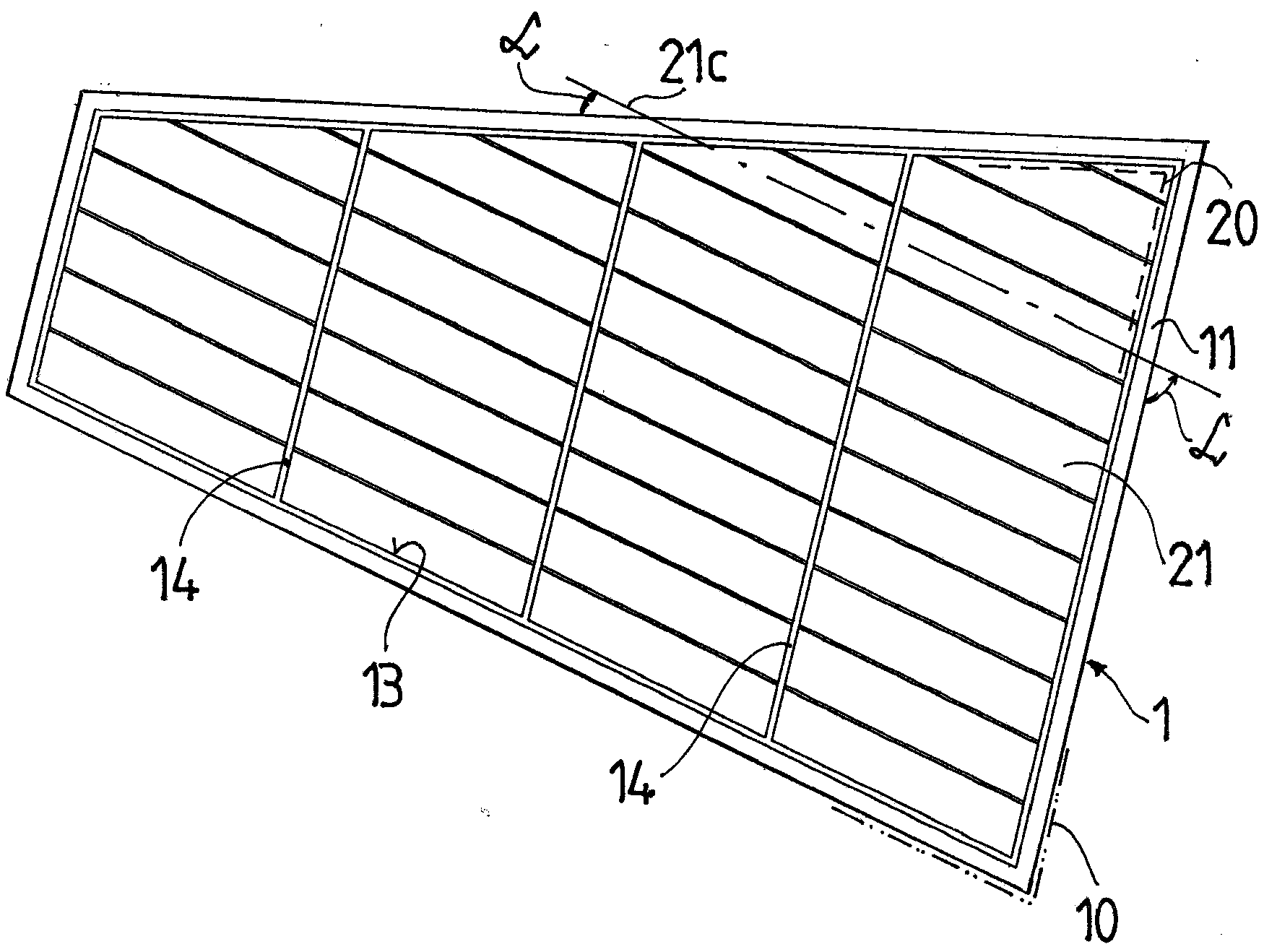

[0026] exist figure 1 Here, the version of the filter panel 1 according to the invention which can be installed into a disc filter unit can be seen in the pre-assembled state. The support frame 10 and the filter insert 20 forming the filter panel 1 can be seen. The support frame 10 includes a first bearing part 11 and a second bearing part 12 . Here, the first carrier part 11 is bounded by edges 11a, 11b, 11c and 11d, and the second carrier part 12 is bounded by edges 12a, 12b, 12c and 12d. Edge 11a-edge 12a, edge 11b-edge 12b, edge 11c-12c, and edge 11d-12d are systematically compliant with respect to each other and to adjacent edges in size, so that the assembled first bearing The part 11 and the second carrier part 12 are adapted to securely hold the filter insert 20 closed between them. Here we have to note that the first carrier part 11 and, of course, the second carrier part 12 can also have three edges, or even more than four edges. The number of edges that the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com