A guide device for a double toggle punch press

A guiding device and double toggle technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of limited movable table area, complex machine manufacturing process, poor machine reliability, etc., and achieve machine parts simplification , the effect of increasing the area and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

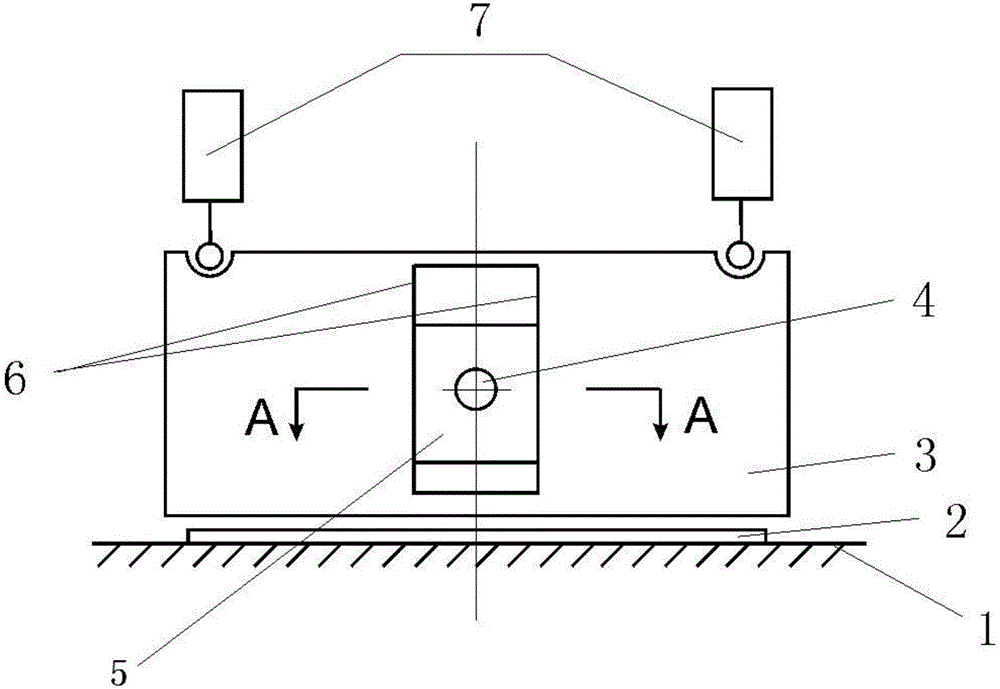

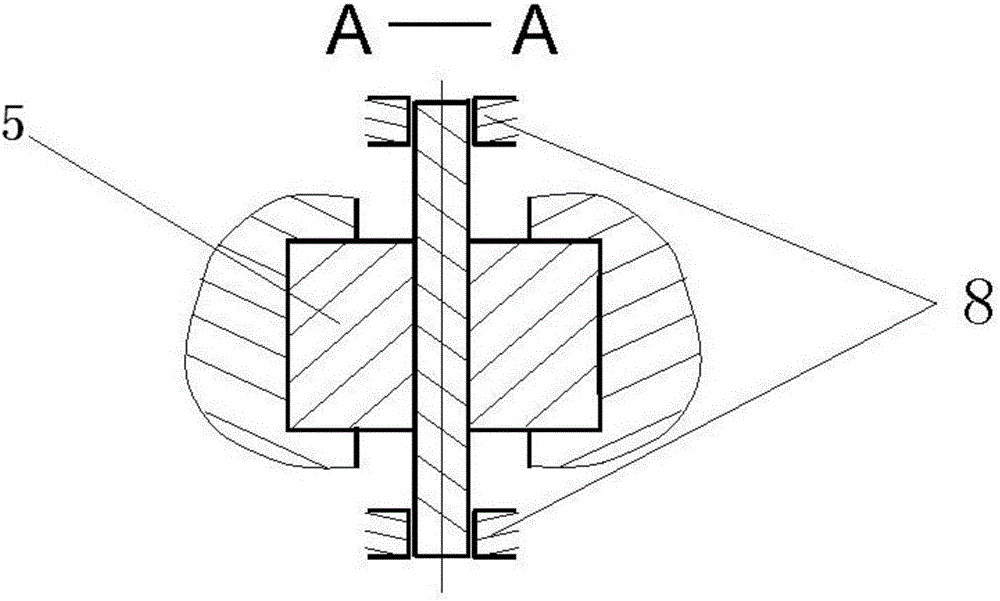

[0014] see figure 1 , the present invention is a kind of double toggle press guide device, including movable table top 3, guide block 5 for guiding, fixed shaft 4 and a pair of driving mechanisms 7; wherein, the center position of movable table top 3 is provided with guide groove 6, The guide block 5 is sleeved in the guide groove 6, the center of the guide block 5 is provided with a round hole, the fixed shaft 4 passes through the round hole of the guide block 5, and its two ends are fixed on the punch frame 8, so that the guide block 5 can be wound around The fixed shaft 4 swings, and the guide groove 6 can slide up and down along the guide block 5. What needs to be emphasized is that the center line of symmetry of the guide groove 6 coincides with the center line of symmetry of the movable table 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com