Self-adaptive skin rolling supporting structure

A rolling support and self-adaptive technology, applied in the direction of support, clamping, positioning device, etc., can solve the problems of bearing stuck, support shaft rolling, and the horizontal movement of the skin cannot be smoothly carried out, and achieve low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

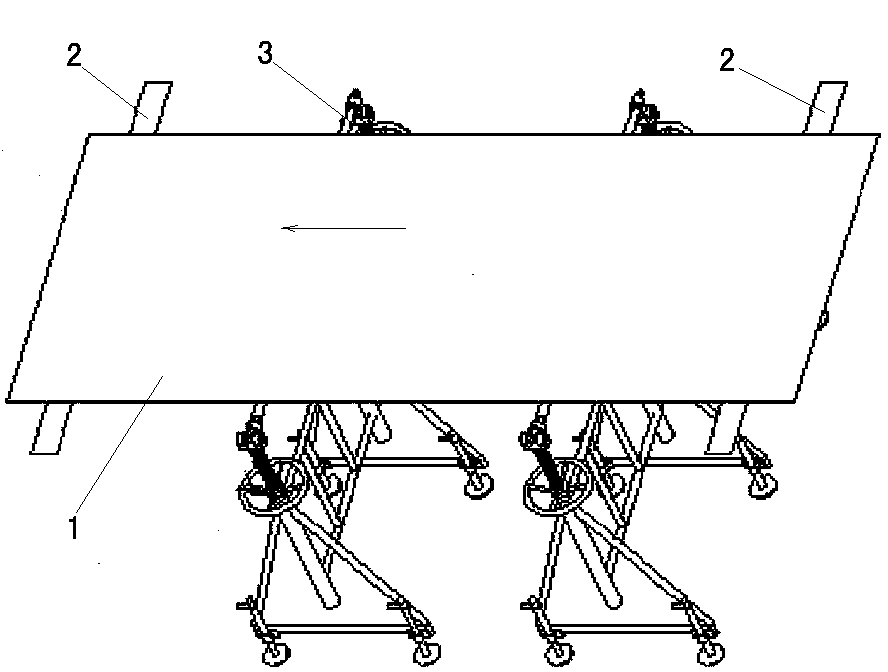

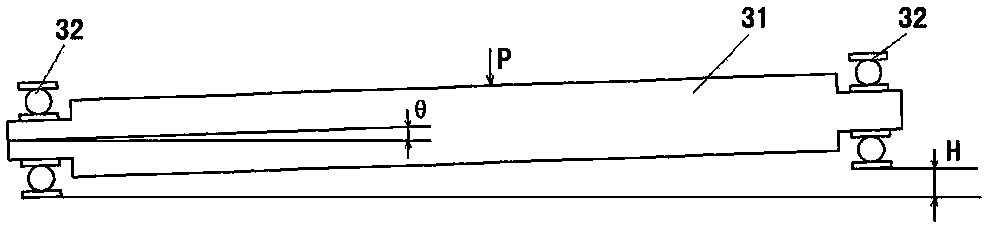

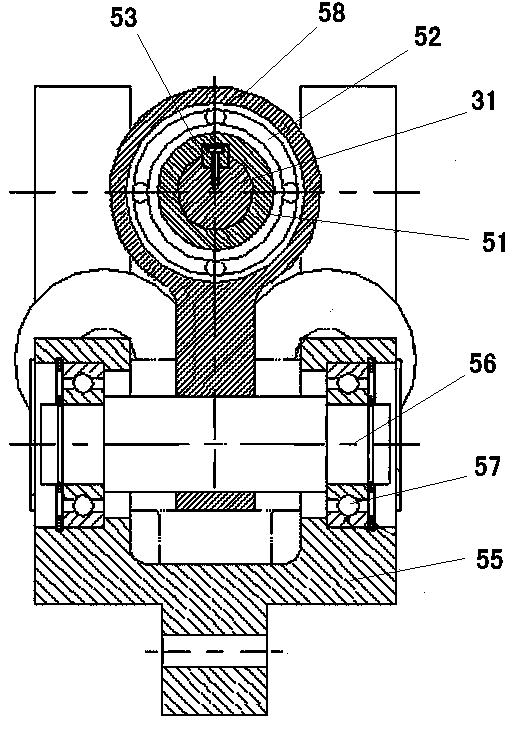

[0012] attached figure 1 It is a schematic diagram of automatic riveting assembly of aircraft flat skin, attached figure 2 It is a schematic diagram of the height difference H between the two ends of the support shaft. In the figure, 1 is the skin, 2 is the skin clamp, 3 is the support mechanism, 31 is the support shaft, 32 is the support bearing, and the arrow indicates the moving direction of the skin. It can be seen from the figure that in the automatic riveting assembly process of aircraft flat skin, the skin first needs to be clamped on the skin fixture, and then the riveting assembly is performed at the specific position of the skin. However, due to the poor rigidity of the skin itself, the skin deforms under the action of gravity, and the place with the largest disturbance in the middle deforms the most, which seriously affects the riveting quality of the skin. To solve this problem, support shafts are usually installed in the middle of the skin support structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com