Electrical Connector Tray

An electrical connector and tray technology, which is applied in the field of low-profile electrical connector trays, can solve the problems of material waste in the production process, cumbersomeness, and increased material consumption, so as to reduce the cost of packaging materials and transportation costs, and increase the storage density. , the effect of reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

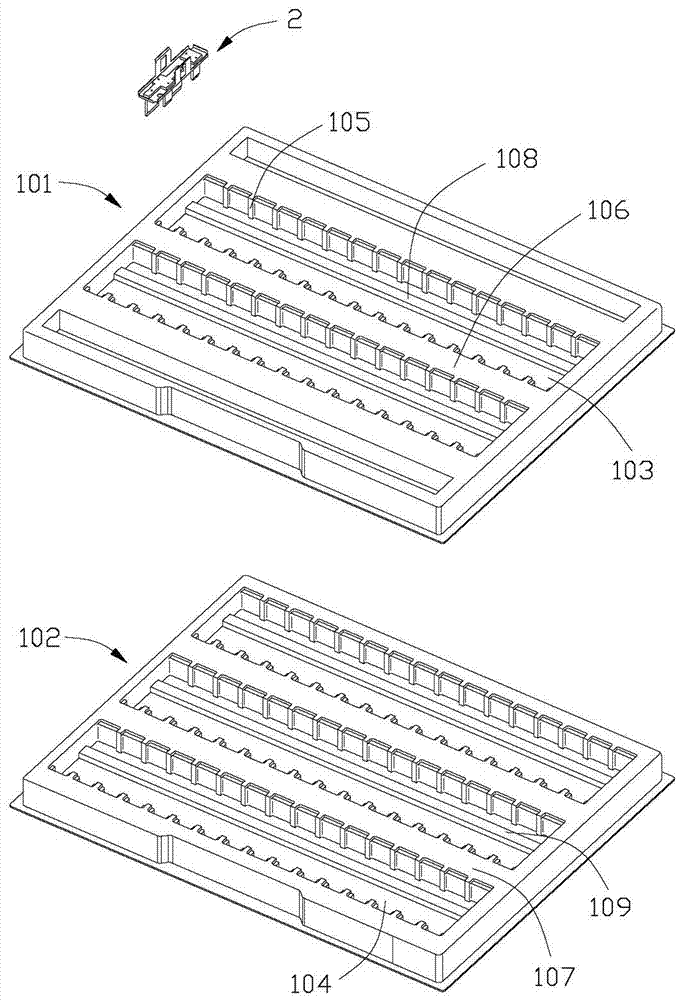

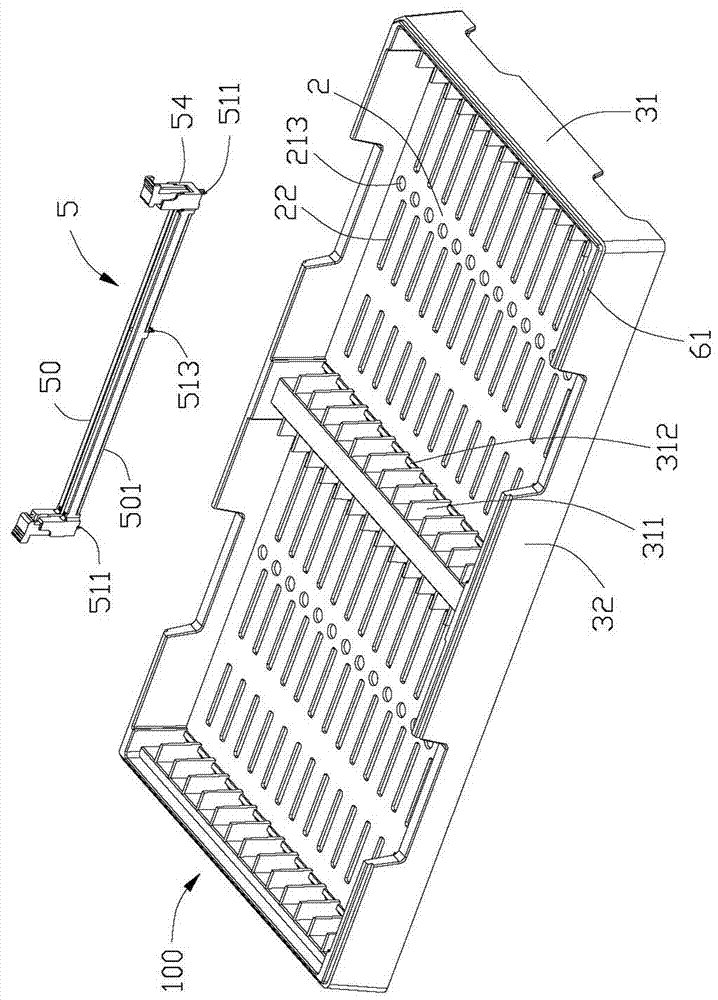

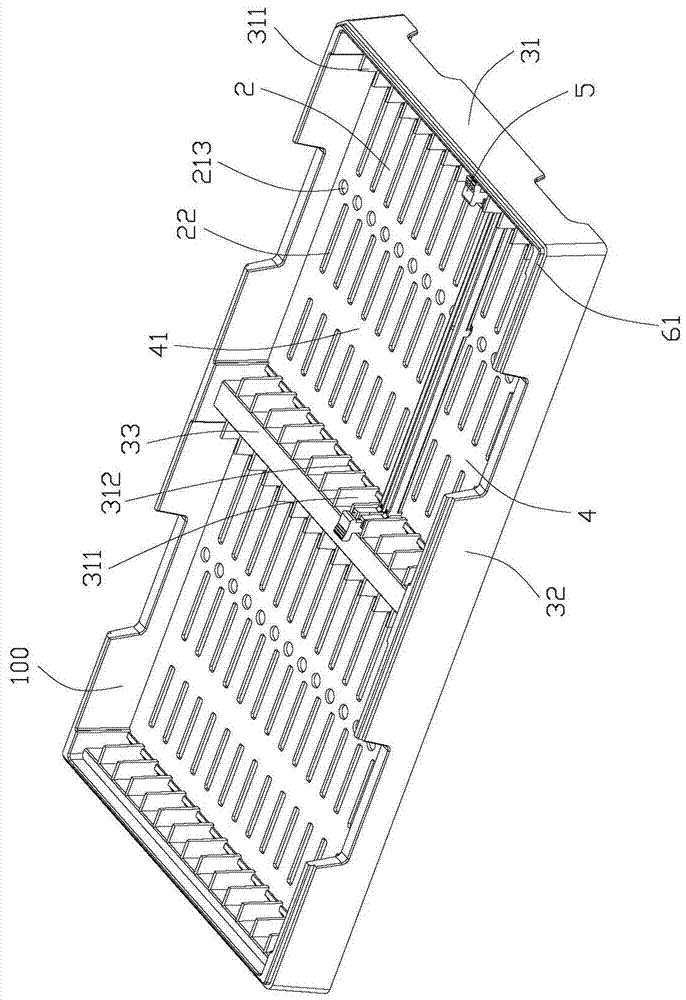

[0019] see figure 2 As shown, the electrical connector tray 100 is used for packing and transporting the electrical connectors 5 . The electrical connector 5 includes a lengthwise insulating body 50, several terminal slots (not shown) arranged side by side along the longitudinal direction of the insulating body 50, and several terminals (not shown) inserted in the terminal slots (not shown). Show). Two locking arms 54 extend vertically from both ends of the insulating body 50 in the longitudinal direction. The insulating body 50 has a bottom 501 , and the insulating body 50 also has a limiting hook 513 vertically extending out of the insulating body 50 from the bottom 501 . The terminals (not shown) are provided with pins (not shown) extending vertically from the bottom 501 of the insulating body 50 to solder the electrical connector 5 to a circuit board (not shown). In this embodiment, the insulating body 50 is further provided with fixing hooks 511 perpendicularly extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com