Integrated type double-self-locking intelligent informatization steel support and loading and detaching method thereof

An integrated, steel-supported technology, applied in excavation, lifting devices, construction, etc., can solve the problems of insecurity, support failure, long time, etc., to avoid damage and engineering accidents, reduce foundation pit deformation, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

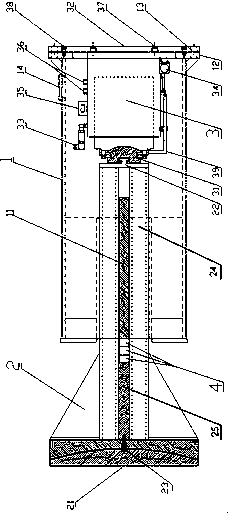

[0058] figure 1 It is a cross-sectional view of the integrated double self-locking intelligent information steel support of the present invention. Such as figure 1 As shown, an integrated double self-locking intelligent information steel support of the present invention includes a cylinder body 1 , a flexible end 2 , an oil cylinder 3 and a steel wedge 4 . The inside of the first end of the cylinder 1 is provided with the oil cylinder 3, the oil cylinder 3 is provided with an oil pressure sensor 33, a displacement sensor 34 and a hydraulic lock 35, and the second end of the cylinder 1 is provided with an opening , a middle main force bearing plate 11 is axially arranged in the opening, and both sides of the middle main force bearing plate 11 are integrally welded with the inner wall of the cylindrical opening, and the active end 2 includes a support shoe 21, Connecting plate 22, bolt 23, several support rods 24 and force bearing plate 25, the first end of described support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com