Cross-railway road bridge protection structure

A technology for road crossing and protective structures, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of inability to effectively prevent vehicles from overturning guardrail hazards, and inability to prevent small falling objects from falling, so as to prevent the impact on railway operation and shorten the interference The effect of time and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

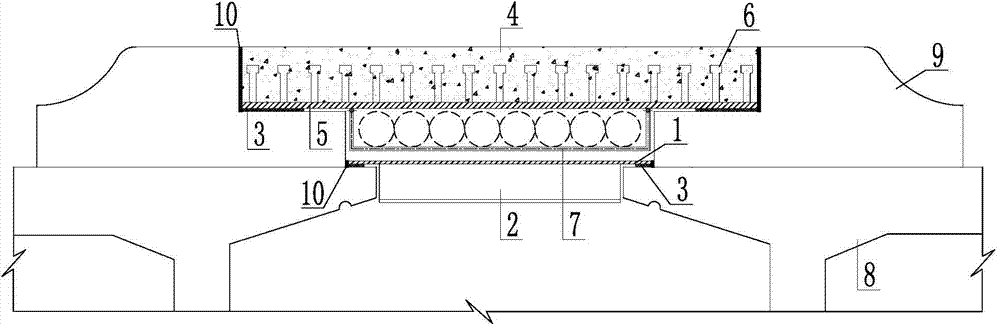

[0028] Such as figure 1 As shown, this embodiment discloses a bridge protection structure for a highway crossing a railway, which is arranged between two bridges to provide effective protection measures for the central divider, and mainly includes a lower cover plate and an upper cover plate. The lower cover plate is welded by steel plates and placed between the main girders 8 at the central divider of the two bridges, so that the bridge forms a closed system and provides safety guarantee for the construction and replacement of the upper cover plate. The upper cover plate is a steel-concrete composite structure, which is placed between the bases of the bridge deck guardrail at the central divider of the two bridges, and can bear the load of vehicles.

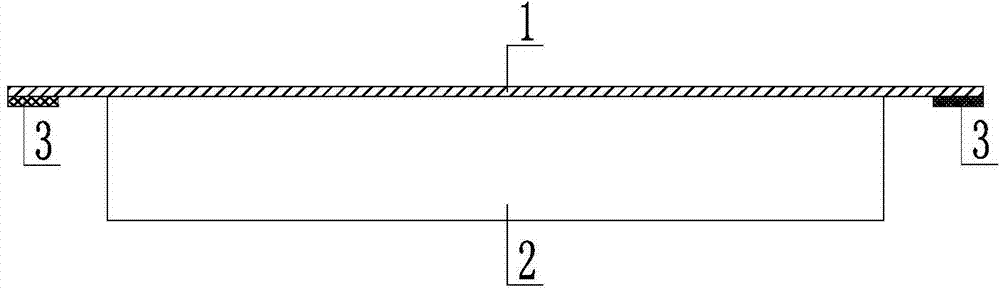

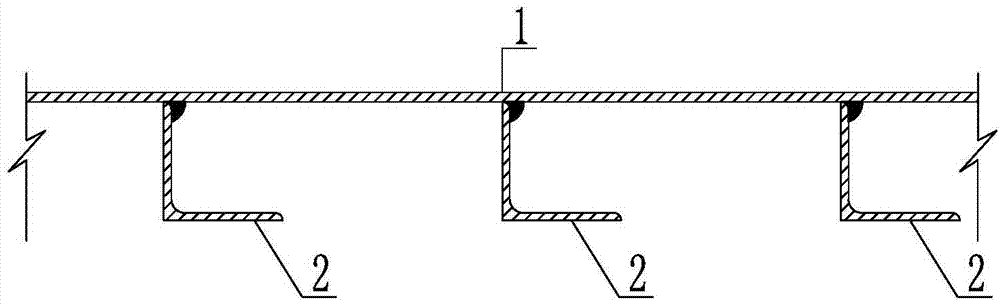

[0029] combine figure 2 and image 3 As shown, the lower cover plate is composed of a lower cover plate steel plate 1, a stiffener 2 and a rubber plate 3. The two sides of the lower cover plate steel plate 1 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com