Backlight module and liquid crystal display device

A technology of backlight module and light guide plate, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of low brightness of backlight source, increased gap between LED and light guide plate, etc., and achieve the effect of ensuring high efficiency and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

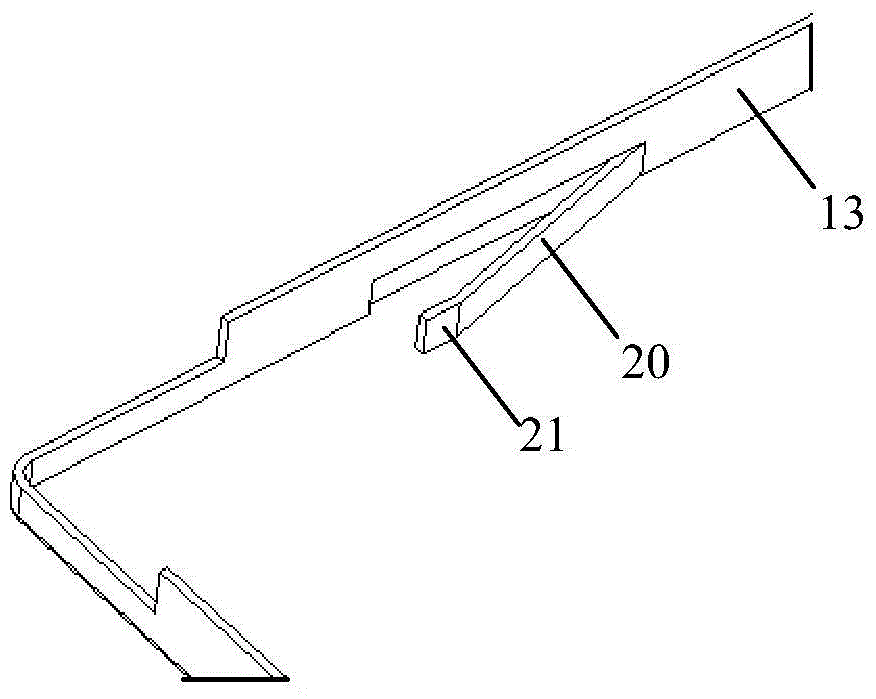

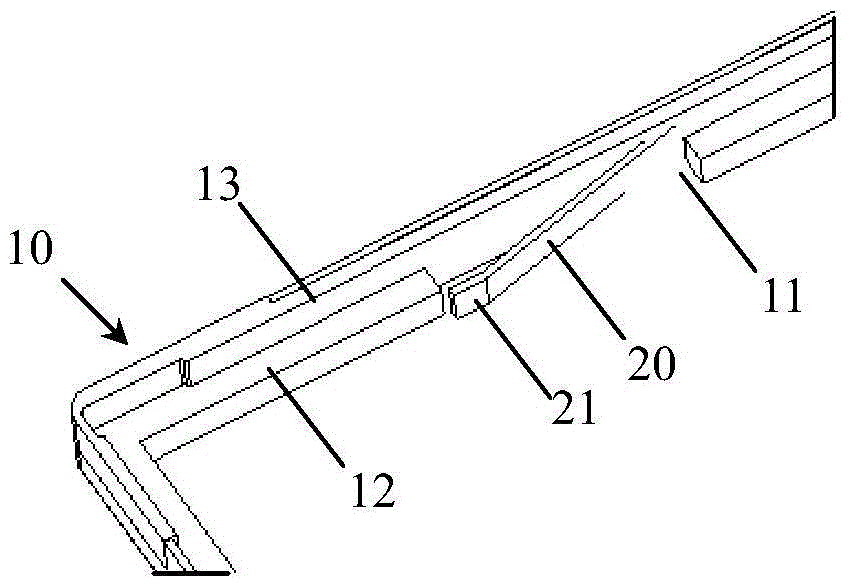

[0031] like figure 2 As shown, a backlight module according to an embodiment of the present invention includes a light guide plate, an LED lamp, and an outer frame 10 for assembling the light guide plate and the LED lamp. One side of the light guide plate is a light incident surface, which is opposite to the position of the LED lamp An elastic piece in a compressed state is provided between the side of the light guide plate opposite to the light-incident surface and the outer frame 10, and a slot 11 is provided on the inner side of the outer frame 10 in contact with the elastic piece, and the slot 11 is used for installing The elastic part is used to position the elastic part to prevent the elastic part from shifting and ensure the elastic contact between the elastic part and the light guide plate. The elastic part can be directly placed in the slot without any other such as gluing or fastening The connection of parts, etc. can simplify the process.

[0032] The outer frame ...

Embodiment 2

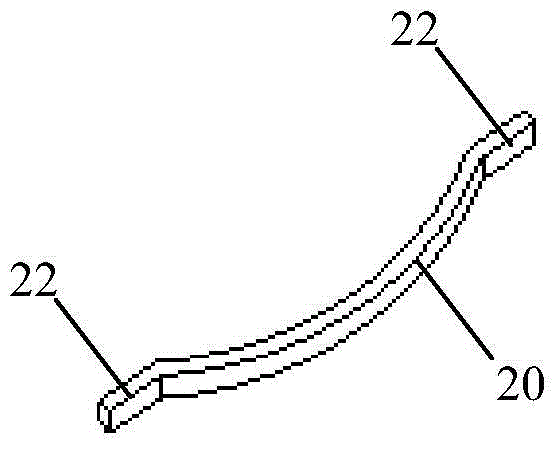

[0038] like image 3 As shown, a backlight module according to an embodiment of the present invention includes a light guide plate, an LED lamp, and an outer frame 10 for assembling the light guide plate and the LED lamp. One side of the light guide plate is a light incident surface, which is opposite to the position of the LED lamp An elastic member is provided between the side opposite to the light incident surface of the light guide plate and the outer frame 10. The elastic member in this embodiment is an arc-shaped elastic piece 20, and the two ends of the elastic piece 20 are connected to the slot 11, wherein The protruding part between them is in contact with the side of the light guide plate, and the elastic member can be directly placed in the slot without any other connections such as glue and fasteners, which can simplify the process.

[0039] Wherein, the outer frame 10 of this embodiment includes a plastic frame 12 and a metal outer frame 13 covering the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com