Plane light source

A flat lamp and substrate technology, which is applied to discharge lamps, gas discharge lamps, and parts of gas discharge lamps, etc., can solve problems such as low brightness, and achieve the effect of enhancing luminous brightness and solving darker brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

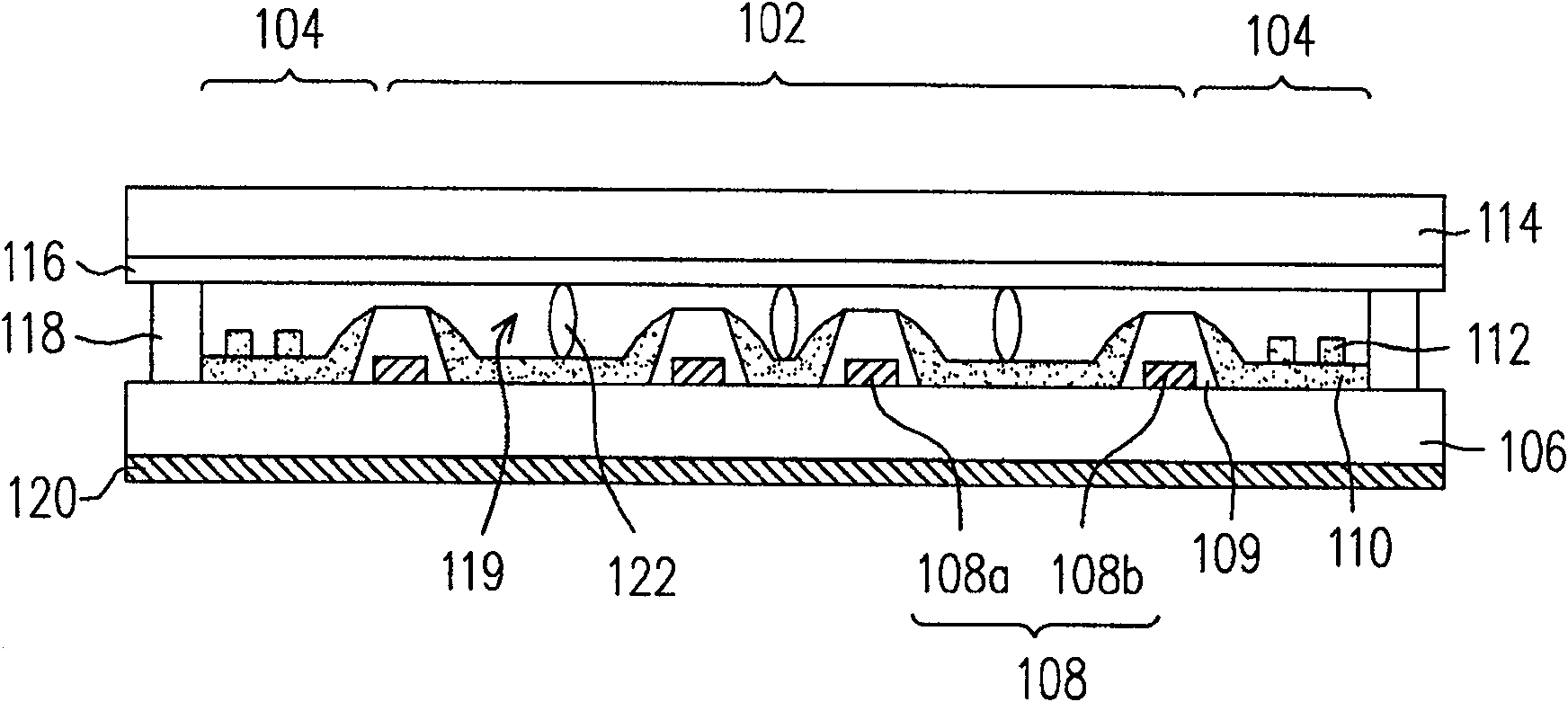

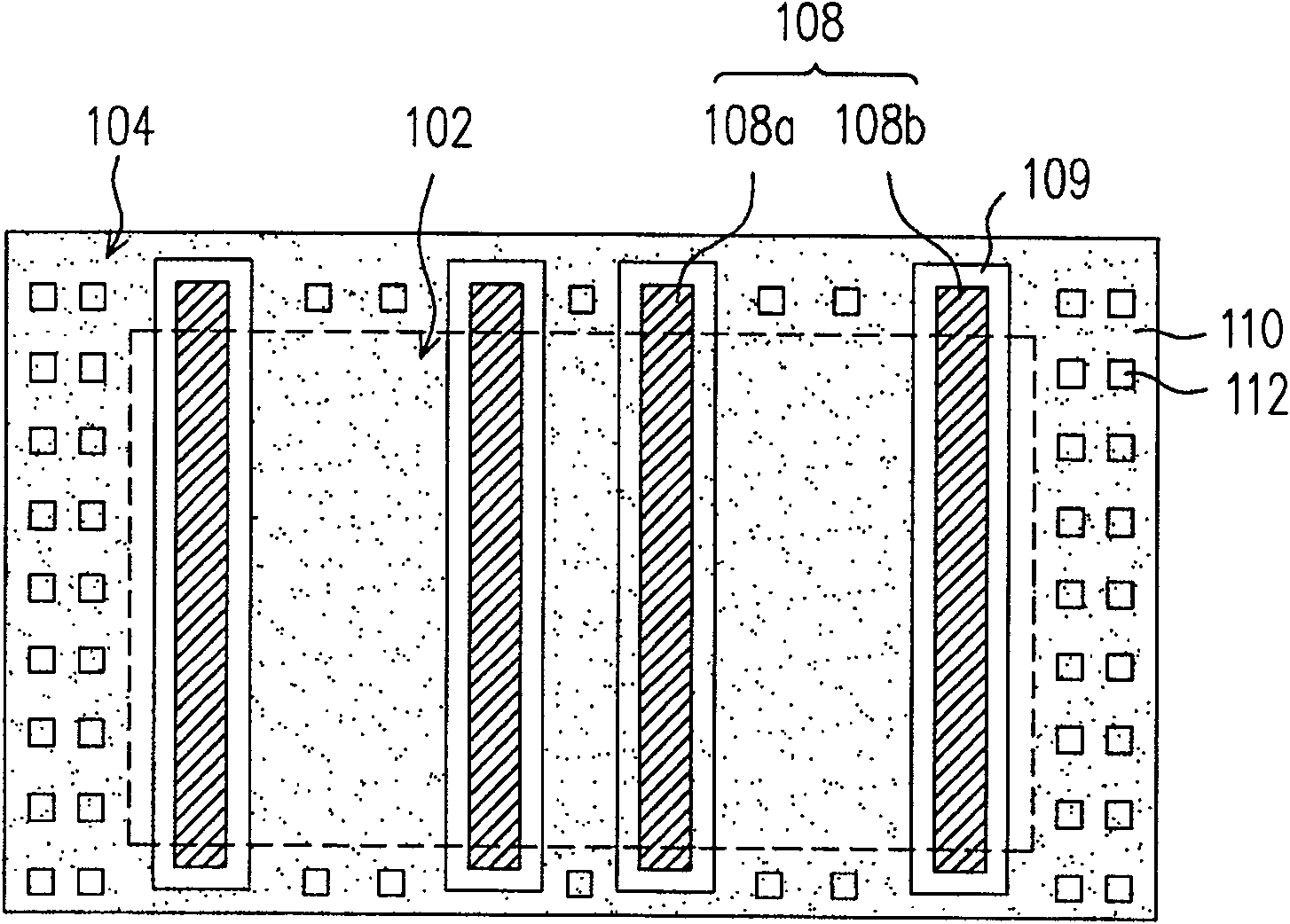

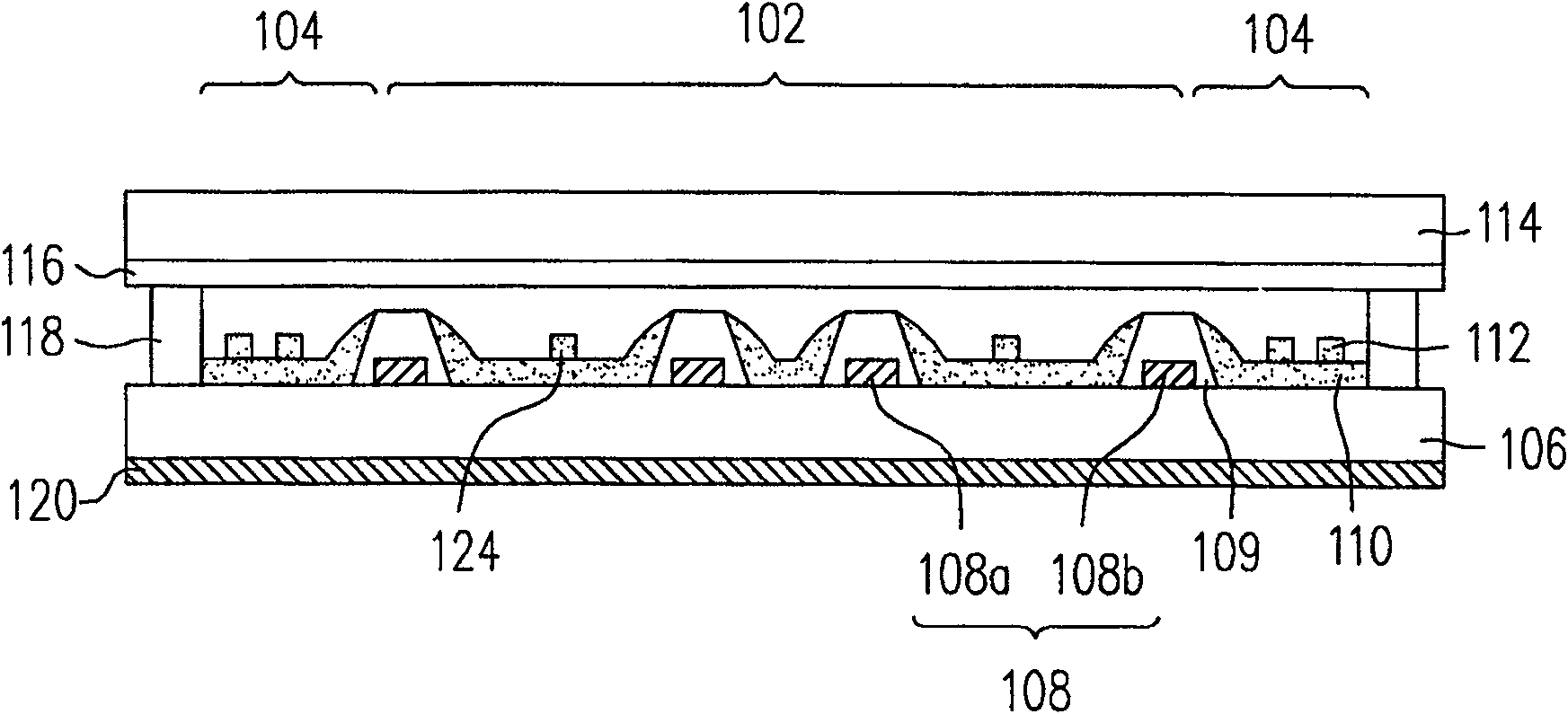

[0039] Figure 1A is a schematic cross-sectional view of a planar light source according to a preferred embodiment of the present invention. Figure 1B yes Figure 1A Top view of the first substrate in the planar light source. Please also refer to Figure 1A and Figure 1B , the planar light source of the present invention has a main body area 102 and an edge area 104 located around the main body area 102 . The planar light source includes a first substrate 106 , a plurality of first electrodes 108 , a second substrate 114 , a sealant 118 , a plurality of dielectric patterns 109 , a fluorescent layer 110 and a plurality of first fluorescent patterns 112 . The material of the first substrate 106 and the second substrate 114 is, for example, transparent glass. The frame glue 118 is disposed between the first substrate 106 and the second substrate 114 outside the edge area 104, and the frame glue 118 is used to join the two substrates 106, 114 together, so that the frame glue 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com