A detection device for preventing wafer fragmentation

A detection device and chip technology, which is applied to electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as chip and chip storage cavity fragmentation, chip processing process is wasted, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

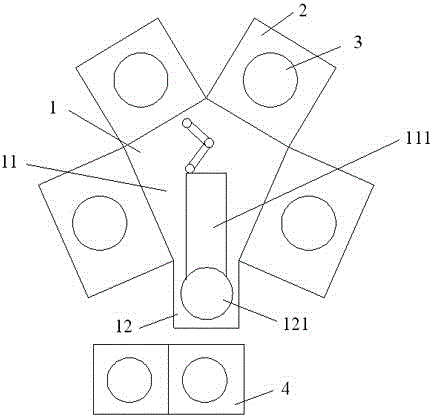

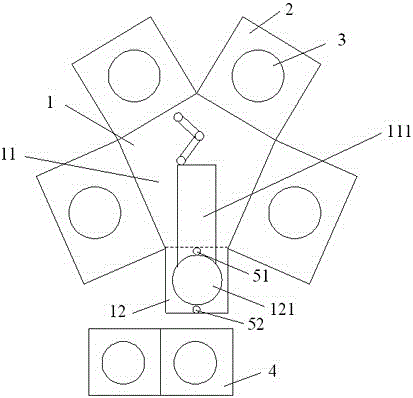

[0023] The following combination image 3 and Figure 4 , taking the P5000 semiconductor device as an example, the specific implementation manner of the present invention will be described in detail.

[0024] Such as image 3 As shown, the P5000 semiconductor equipment is a semiconductor equipment with multiple processing chambers, capable of accommodating and processing 5-inch, 6-inch or 8-inch wafers. It includes a transfer chamber 1, and four processing chambers 2 arranged around the transfer chamber 1 in a star shape. Each processing chamber 2 is respectively connected to the transfer chamber 1 through an isolation valve, and each processing chamber 2 is respectively provided with a loading platform 3 for carrying and positioning the wafer when processing the wafer.

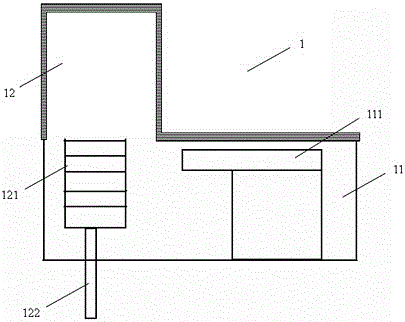

[0025] Such as image 3 and 4 As shown, the transfer chamber 1 includes a wafer transfer buffer chamber 11 and a wafer storage chamber 12 , and the top of the wafer storage chamber 12 is higher than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com