Wafer clamping device utilizing spring tensioning force feedback and motor driving force feedback

A technology of motor drive and clamping device, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve the problems that the wafer clamping device is not suitable for large-size wafers, wafer transmission pollution, etc., to ensure reliability Sexuality, avoiding cross-contamination, and solving the effect of transmission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

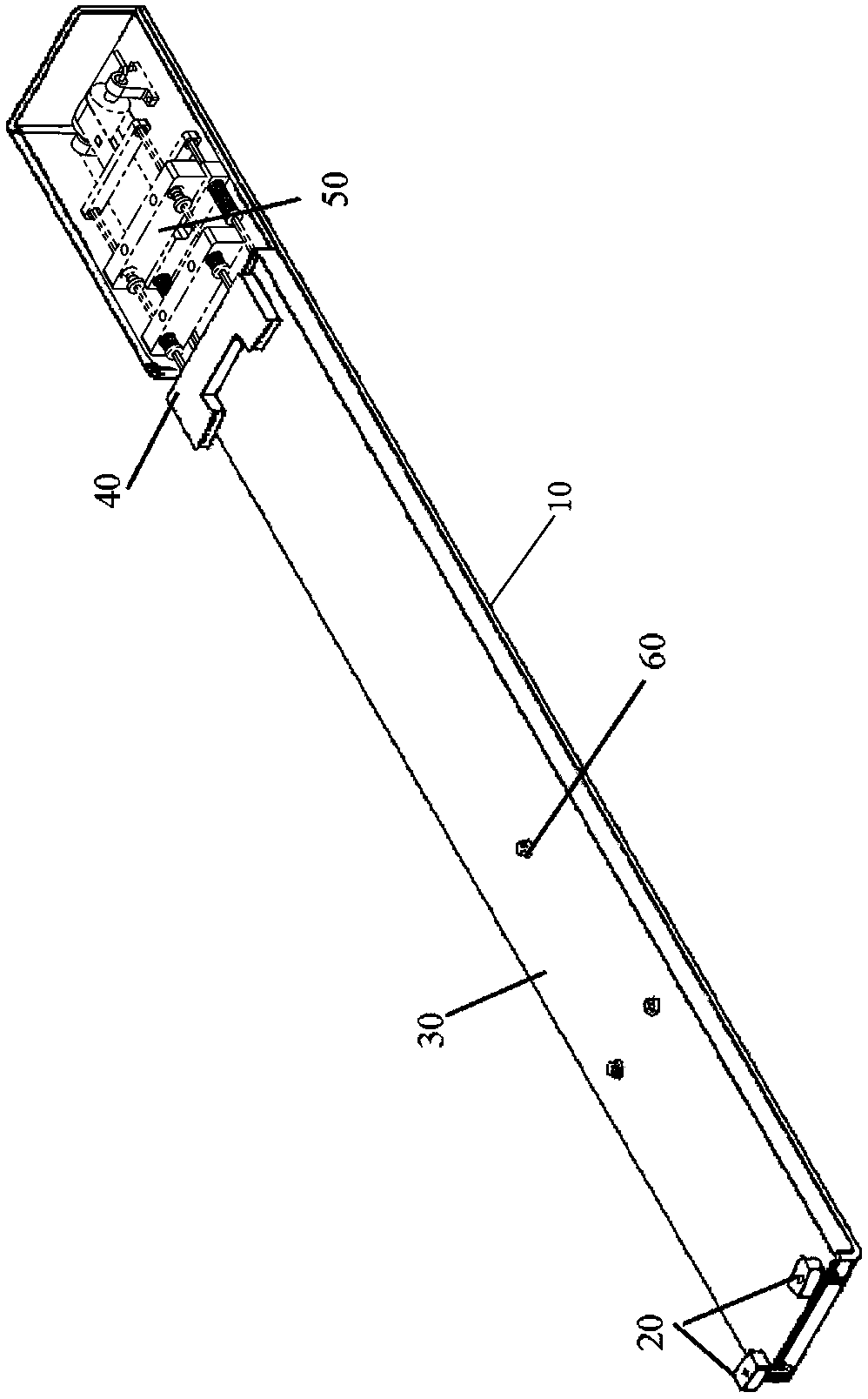

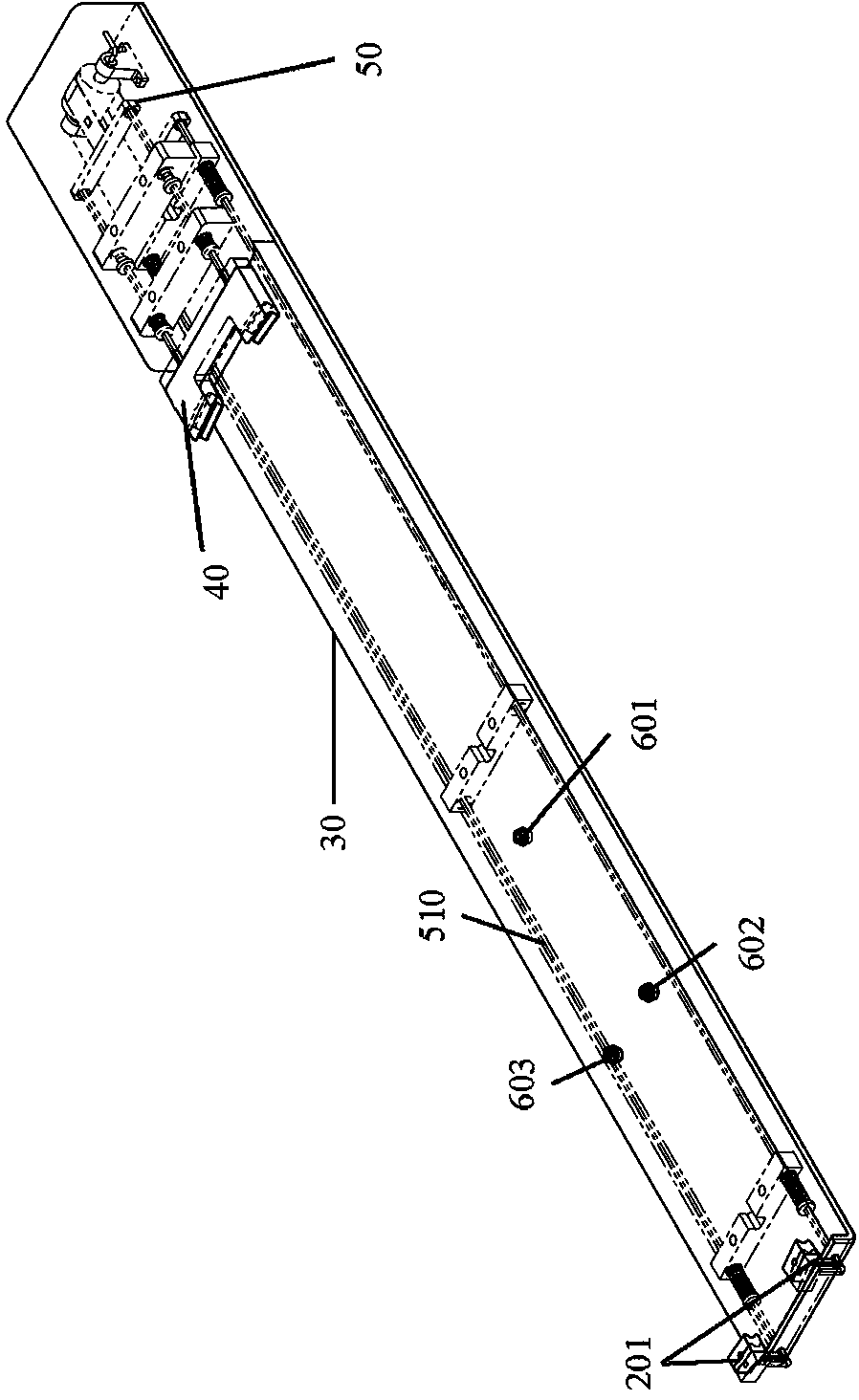

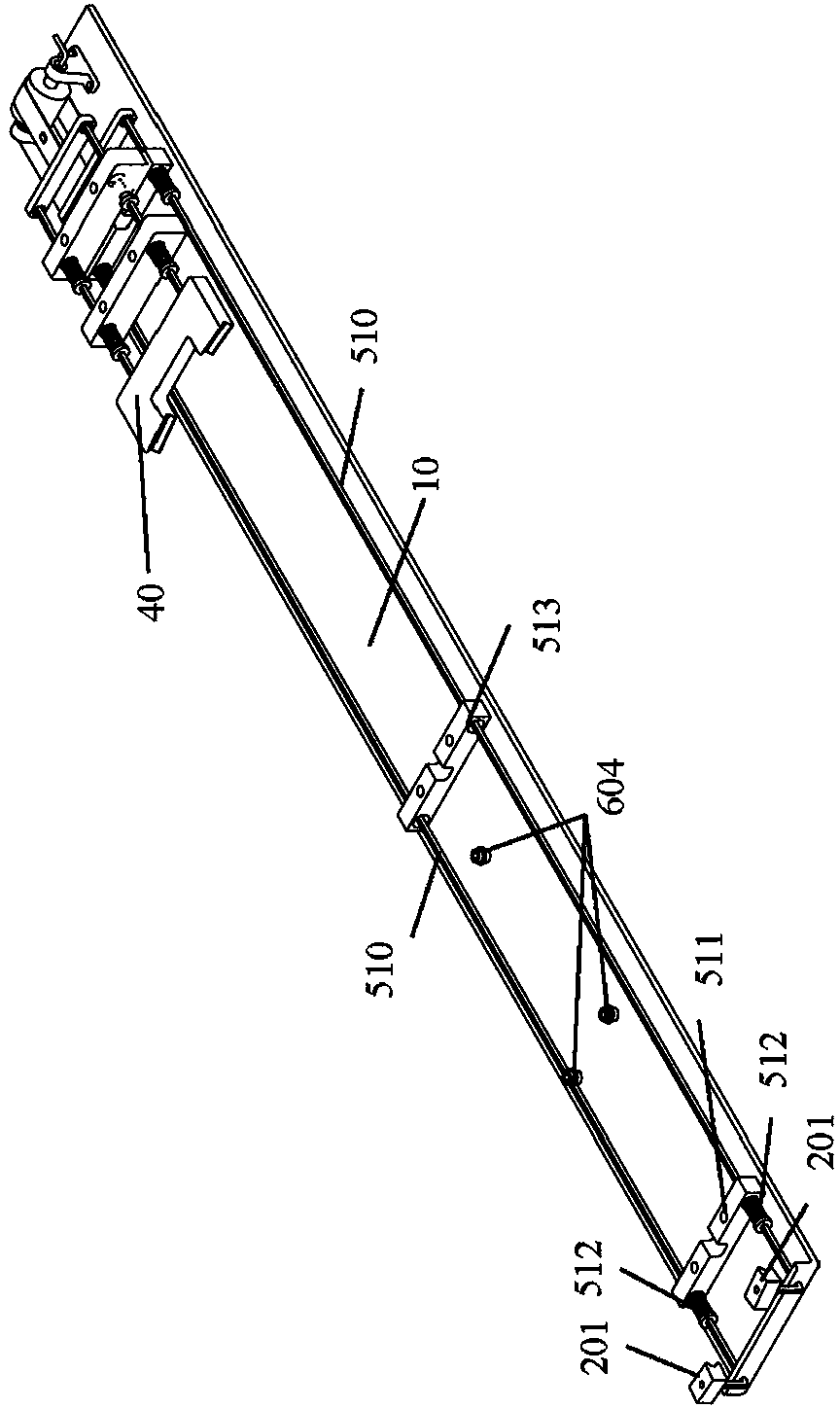

[0050] Examples see Figure 1-3 As shown, the force feedback wafer clamping device using spring tension and motor drive includes a base 10 and a front clamp 20 and a rear clamp 40 arranged on the base 10 for clamping a wafer. The base 10 is also provided with a driving mechanism 50 for controlling the movement of the front clamp 20 and the rear clamp 40 (ie, adjusting the clamping distance).

[0051] see Figure 3-6 , the driving mechanism 50 is made up of the front clip connection mechanism, the rear clip connection mechanism and the power source.

[0052] The power source is arranged on the base 10 behind the rear clamp 40, and includes a transmission belt 506 (synchronous belt or chain), a drive unit 507 and a drive unit support 508, and the drive unit 507 is placed on the base through the drive unit support 508 10, the transmission belt 506 is engaged with the drive unit 507, and is driven by the drive unit 507 to alternately reciprocate left and right, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com