Preparation method of polyelectrolyte-coated LiNi0.5Mn1.5O4 positive electrode material

A polyelectrolyte and positive electrode material technology, which is applied in the preparation of high-voltage positive electrode materials for lithium-ion batteries and the preparation of surface-coated spinel-type high-voltage lithium nickel manganese oxide positive electrode materials. It can solve the cumbersome process and high-temperature calcination and other problems, to achieve the effect of high rate, high specific capacity, and enhanced compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

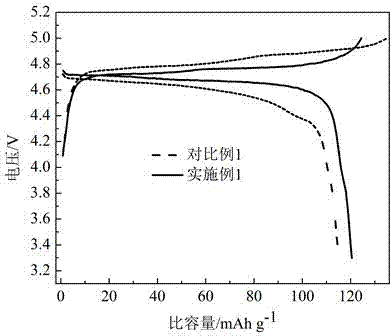

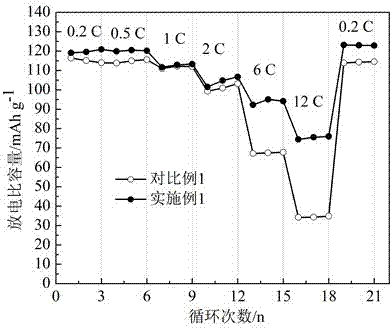

Embodiment 1

[0024] Weigh 10.2g of polyacrylic acid with an average molecular weight of 3000 into a 200ml evaporating dish, weigh LiOH·H 2 O 2.32g, dissolved in 36g of distilled water to obtain LiOH solution, the LiOH solution was added dropwise to the evaporating dish until the pH value of the solution was 8, the above-mentioned solution was initially steamed to a viscous shape at 80°C on the electric heating mantle, and then the mixture was Move to a vacuum oven and dry in vacuum at 100 °C for 24 h to obtain PAALi as a white solid. Weigh LiNi 0.5 mn 1.5 o 4 The finished product is 4.975 g, PAALi is 0.025 g, and the mass fraction of PAALi in the mixture is 0.5%. LiNi to be weighed 0.5 mn 1.5 o 4 , PAALi 0.025g was fully dissolved and mixed in 5mL of water, and after preliminary stirring and evaporation on the electric heating mantle, it was moved to a vacuum drying oven at 100°C for 24 hours to obtain 5g of LNM0.5%PAALi powder sample.

[0025] Weigh 0.1 g of Super P, 0.8 g of LNM0....

Embodiment 2

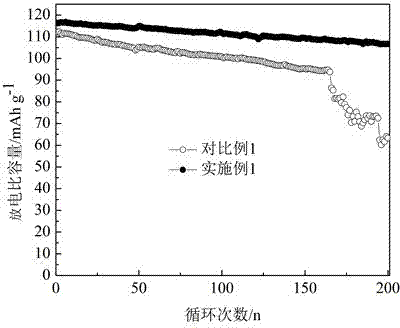

[0027] According to the method described in Example 1, PAALi was prepared. Weigh LiNi 0.5 mn 1.5 o 4 Finished product 4.8500 g, PAALi 0.150 g, the mass fraction of PAALi in this mixture is 3%. LiNi to be weighed 0.5 mn 1.5 o 4 , 0.150 g of PAALi was fully dissolved and mixed in 5 mL of water, and after preliminary stirring and evaporation on the electric heating mantle, it was moved to a vacuum drying oven at 100 ° C for 24 hours to obtain 5 g of LNM3% PAALi powder sample. Prepare and assemble the battery according to the method described in Example 1, and measure its discharge specific capacity at 0.2 C, 0.5 C, 1 C, 2 C, 6 C, 12C and 0.2C to be 118.5 mAh / g and 116.7 mAh / g respectively , 113.7 mAh / g, 110.6 mAh / g, 99.1 mAh / g, 84.6 mAh / g and 119.5 mAh / g; then it was measured at 1 C for 200 charge-discharge cycles, and the capacity retention rate was 88.9%.

Embodiment 3

[0029] According to the method described in Example 1, PAALi was prepared. Weigh LiNi 0.5 mn 1.5 o 4 Finished product 4.9500 g, PAALi 0.050 g, the mass fraction of PAALi in this mixture is 1%. LiNi to be weighed 0.5 mn 1.5 o 4 , 0.050 g of PAALi was fully dissolved and mixed in 5 mL of water, stirred and evaporated on the electric heating mantle, and then moved to a vacuum drying oven at 100 ° C for 24 hours to obtain 5 g of LNM1% PAALi powder sample. Prepare and assemble the battery according to the method described in Example 1, and measure its discharge specific capacity at 0.2 C, 0.5 C, 1 C, 2 C, 6 C, 12C and 0.2C to be 125.5 mAh / g and 121.5 mAh / g respectively , 117.3 mAh / g, 110.6 mAh / g, 96.3 mAh / g, 74.1 mAh / g and 122.7 mAh / g; then it was measured at 1 C for 200 charge-discharge cycles, and the capacity retention rate was 84.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap