Tubular body having decorative layer and method for forming decorative layer on tubular body

A technology for decorative layers and tubular bodies, applied in the field of tubular bodies, can solve problems such as damage to the decorative appearance, breakage, peeling of the decorative layer, etc., and achieve a good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, one embodiment of the tubular body provided with the decorative layer and the method of forming the decorative layer on the tubular body according to the present invention will be described with reference to the drawings.

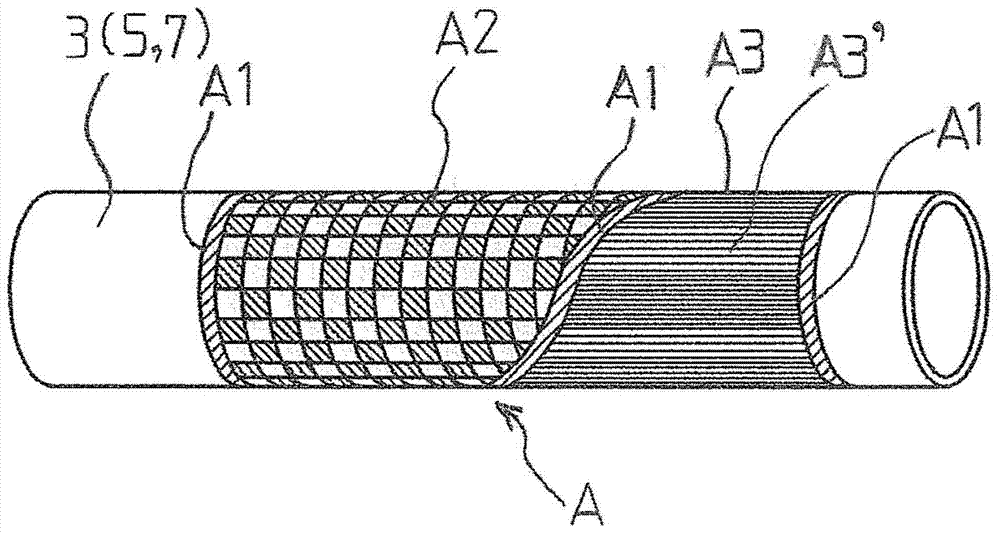

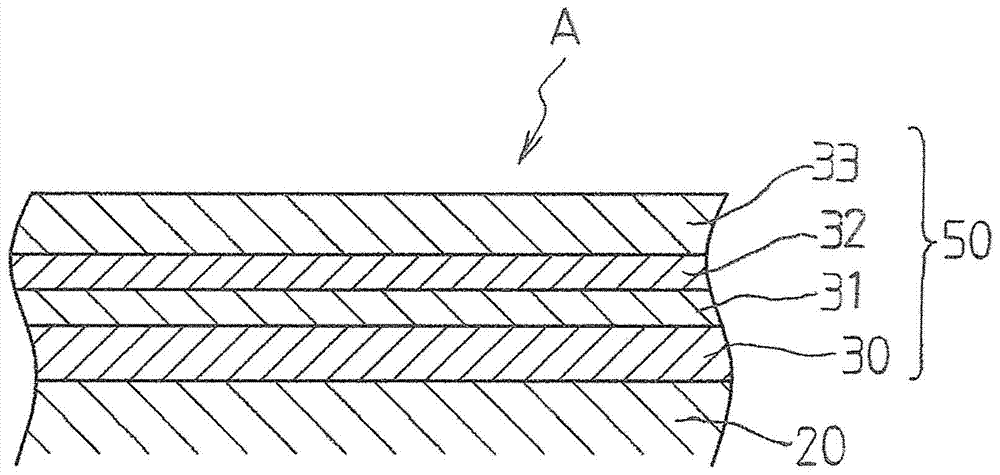

[0030] exist figure 1 2 shows the fishing rod 1 as an example of the tubular body of the present invention. As shown in the figure, the fishing rod 1 is composed of a plurality of rod shafts as tubular bodies, specifically, a first section rod 3 with a handle 3a, a first middle rod 5, a second middle rod 7, and a fishing line stop. The rod tip section 9 of the moving part 9a is formed. At this time, each pole 3, 5, 7 is constituted with a pull-out type or a plug-in type, and constitutes the pole body of each pole 3, 5, 7 (raw material body 20, refer to image 3 ) is formed by winding a fiber-reinforced polyester film impregnated with a reinforcing fiber and a synthetic resin (it can also be formed by metal such as steel), and a decorative par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com