Three-chamber infusion bag and production method thereof

A production method and technology of infusion bags, which are applied in the field of three-chamber infusion bags and sealed containers for infusion preparations, can solve the problems of being easily broken through, the bag membranes on both sides are not easy to separate the opening, and accidental mixing of medicines, etc., to achieve self-sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

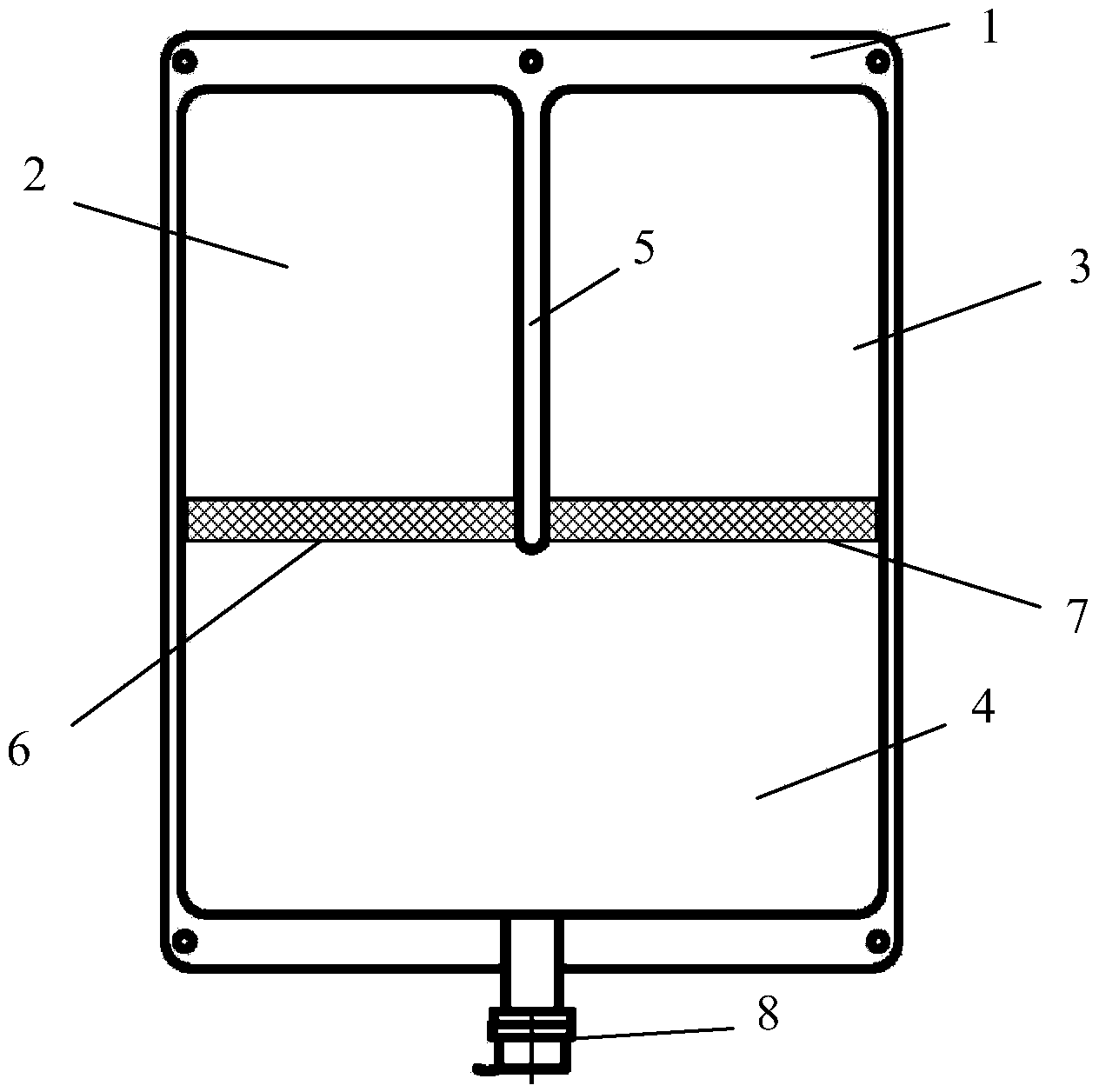

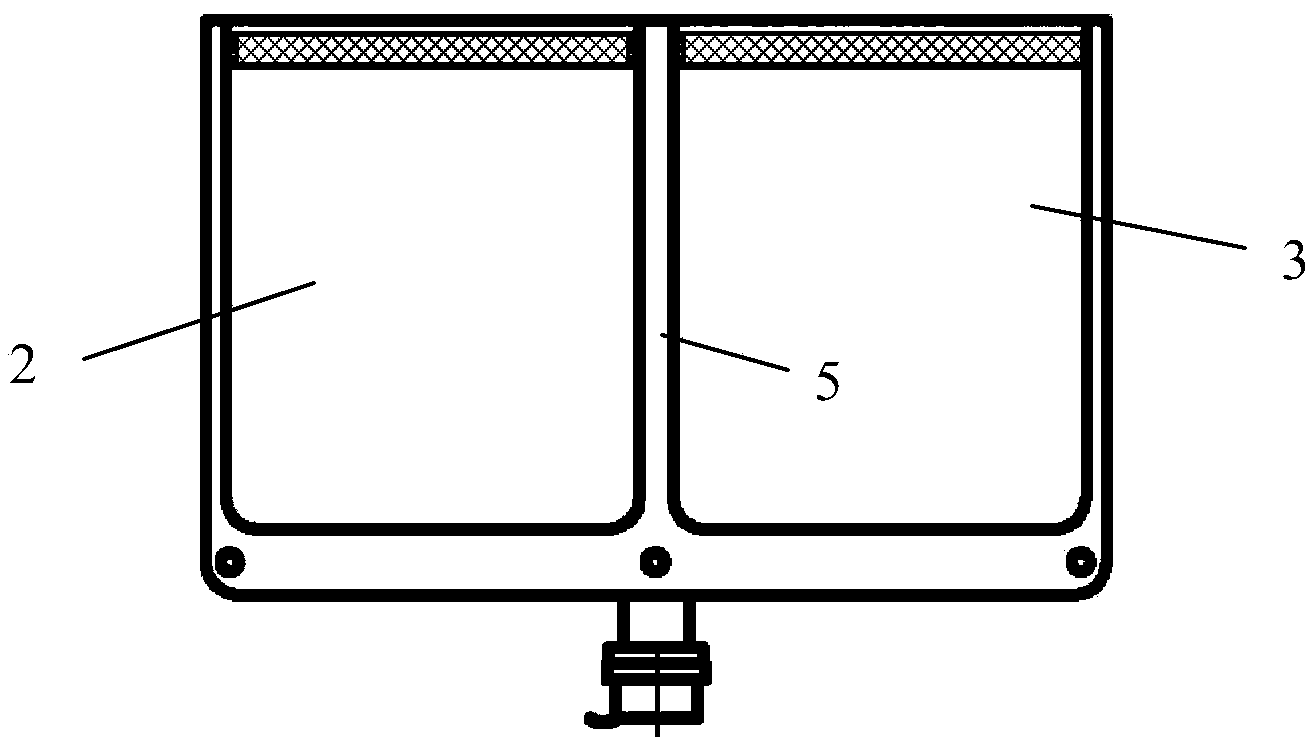

[0022] Such as figure 1 As shown, the three-chamber transfusion bag of the present invention comprises a sealed soft transfusion bag 1, and the soft transfusion bag 1 comprises a front side bag film and a rear side bag film, and the front side bag film and the rear side bag film The side bag film is fixedly connected by a permanent welding structure at its periphery, and there is a first chamber 2, a second chamber 3 and a third chamber 4 between the front side bag film and the rear side bag film. The first chamber 2 and the second chamber 3 are arranged side by side and both are located above the third chamber 4, wherein the first chamber 2 and the second chamber 3 are connected by a The strip-shaped permanent welded structure 5 is isolated, and the strip-shaped permanent welded structure 5 is formed by connecting the front side bag film and the rear side bag film, and the first chamber 2 and the third chamber 4 are provided by a Between the front side bag film and the back ...

Embodiment 2

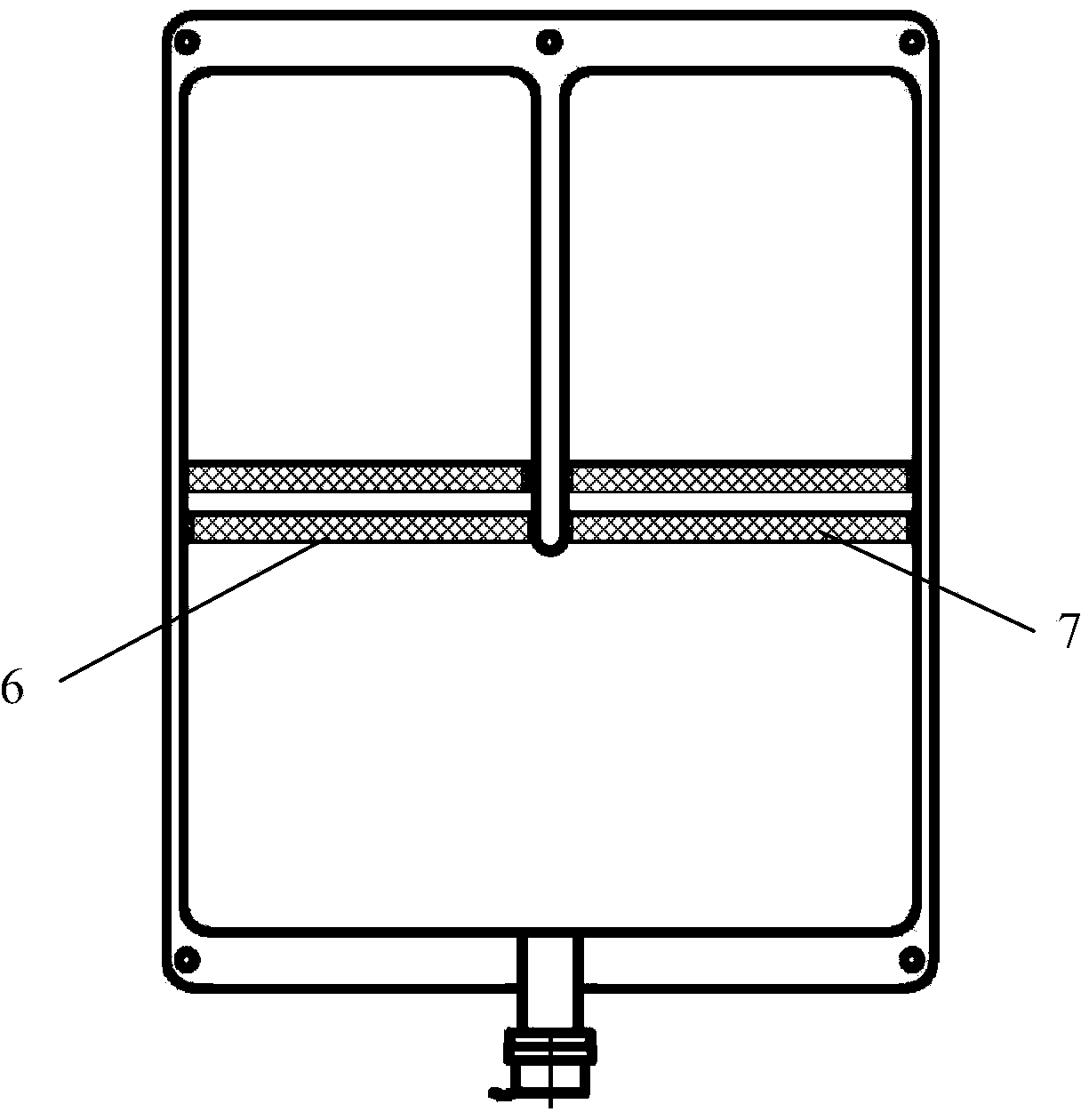

[0026] Such as figure 2 , image 3 with Figure 4 As shown, a third strip-shaped peelable virtual welding structure is arranged between the first chamber 2 and the third chamber 4, and the third strip-shaped peelable virtual welding structure is connected to the first The strip-shaped peelable virtual weld structure 6 is parallel, and a fourth strip-shaped peelable virtual weld structure is arranged between the second chamber 3 and the third chamber 4, and the fourth strip-shaped peelable virtual weld structure The structure is parallel to the second strip-shaped peelable virtual soldering structure 7 .

[0027] Further, the first strip-shaped strip-shaped virtual weld structure 6 and the second strip-shaped strip-shaped virtual weld structure 7 are all located on a straight line, and the third strip-shaped strip-shaped virtual weld structure and the fourth strip-shaped virtual weld structure The strippable virtual solder structures are all located on another straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com