Large-size sand box

A sand box, large-scale technology, applied in the field of fixtures, can solve the problems of high manufacturing cost, low utilization rate, large floor space, etc., and achieve the effects of convenient use and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

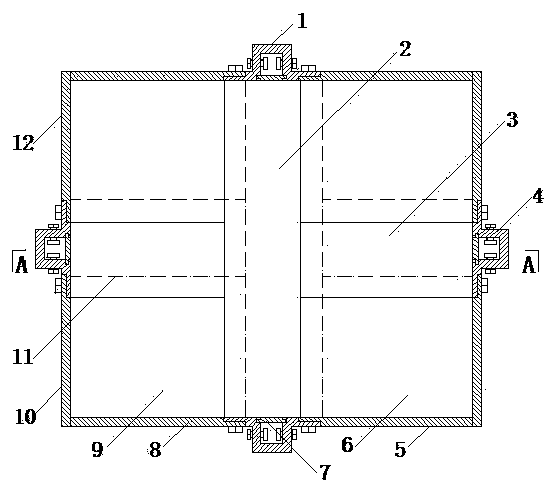

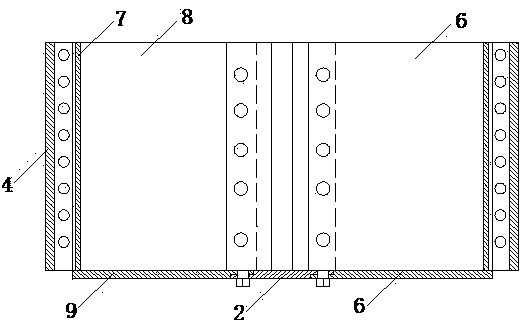

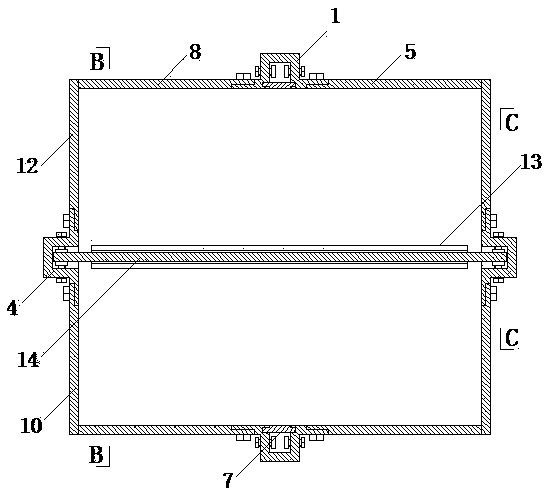

[0036] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 10 , Figure 11 As shown, the large sand box of the present invention includes a base plate, a longitudinal side plate, a transverse side plate and a transverse dividing plate 14 when producing two castings with the same specifications at the same time. The bottom plate, the longitudinal side plates and the transverse side plates are fixedly connected with each other to form a box body. The longitudinal side panels include a longitudinal groove bar body 4 , a first longitudinal side panel 12 and a second longitudinal side panel 10 . The cross-section of the longitudinal groove bar body 4 is a concave shape, and the two groove walls of the longitudinal groove bar body 4 are fixedly connected with the first longitudinal side plate 12 and the second longitudinal side plate 10 respectively, so that the longitudinal groove bar body 4 The groove openings point into the box. The groove...

Embodiment 2

[0043] Embodiment two: if Figure 6 As shown, the large-scale flask of the present invention also includes a longitudinal partition 16 when producing two castings with different specifications at the same time. The transverse side plate includes a transverse groove bar body 1 , a first transverse side plate 8 and a second transverse side plate 5 . The two groove walls of the transverse groove bar body 1 are fixedly connected with the first lateral side plate 8 and the second lateral side plate 5 respectively, so that the groove opening of the transverse groove bar body 1 points to the box. One end of the longitudinal partition 16 is placed in the groove of the transverse groove bar 1 of the lateral side plate, and the other end is fixedly connected with the transverse partition 14 . The longitudinal partition 16 is detachably and fixedly connected with the groove of the transverse groove bar body 1 . Transverse partition 14 and longitudinal partition 16 divide the space in t...

Embodiment 3

[0045] Embodiment three: as Figure 7 , Figure 8 As shown, when the large-scale sand box of the present invention is used as the simultaneous production of four castings with the same specifications, a longitudinal partition 17 has been added relative to the second embodiment. One end of the longitudinal partition 16 and one end of the longitudinal partition 17 are respectively detachably and fixedly connected to the groove of the transverse groove bar body 1, and the other ends are tenon-jointed with the side wall of the transverse partition 14 respectively. Vertical partition 16, longitudinal partition 17 and transverse partition 14 divide the space in the sand box into four spaces of the same size. Longitudinal dividing plate 16, longitudinal dividing plate 17 also can be to synthesize a whole piece and cross transverse dividing plate 14 and vertically separate the space in the sand box into four spaces of the same size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com