A wax collector with built-in porous metal foam with gradient structure

A porous metal foam, gradient structure technology, applied in the field of powder metallurgy, can solve the problems of product carbonization, organic forming agent blockage, quality fluctuation of sintered products, etc., and achieve the effect of convenient recovery and efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

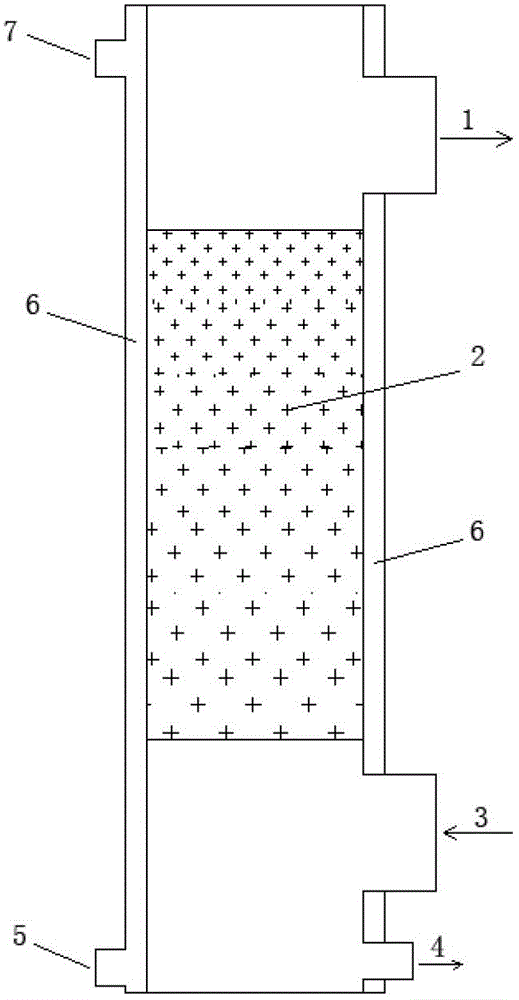

[0019] Such as figure 1 As shown, a vertical metal cylinder 6 with a water jacket on the outer shell, the metal cylinder has a built-in porous foam metal copper 2 with a gradient structure; the lower side wall of the metal cylinder is provided with an air inlet 3; the upper side wall of the metal cylinder is provided with There is an air outlet 1, and the bottom side wall of the metal cylinder is provided with a wax discharge port 4; the lower side wall of the water jacket is provided with a water inlet 5, and the upper side wall of the water jacket is provided with a water outlet 7. The through-porosity of porous copper foam is ≥98%; according to the direction of the entry and discharge of waxy gas, the porosity of porous copper foam is 60%~90%, and the pore diameter is in the range of 0.5~5mm from large to small, in a gradient arrangement . The water jacket of the metal cylinder 6 passes cooling circulating water during dewaxing and sintering; heat circulating water passes ...

Embodiment 2

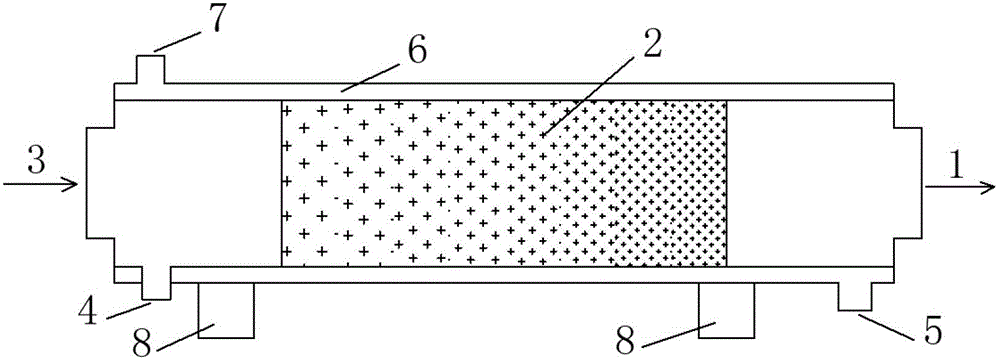

[0024] Such as figure 2 As shown in the figure, a horizontal metal cylinder 6 with a water jacket on its outer shell has a built-in gradient structure of porous nickel foam and porous copper foam 2; the left side of the metal cylinder is provided with an air inlet 3; the right side of the metal cylinder is The side is an air outlet 1; the bottom side wall of the metal cylinder is provided with a wax discharge port 4; the lower wall on the right side of the water jacket is provided with a water inlet 5, and the upper wall on the left side of the water jacket is provided with a water outlet 7. The through-porosity of porous nickel foam and porous copper foam with gradient structure is ≥98%; the porosity of porous nickel foam is 70%~98%, and the pore diameter is 2~10mm; the porosity of porous copper foam is 50%~70%, The pore diameter is 0.1~2mm, and the two are arranged in front and back along the direction of the entry-exit of the polyethylene glycol-containing gas, and the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com