Liquid anti-sloshing storage tank with rotatable cross-shaped blades and anti-sloshing method

A cross-shaped, liquid sloshing technology, used in large containers, containers, packaging, etc., can solve the problems of large local stress at the solid connection between the anti-sloshing structure and the tank, fatigue damage of the tank, and complex coupling of the tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

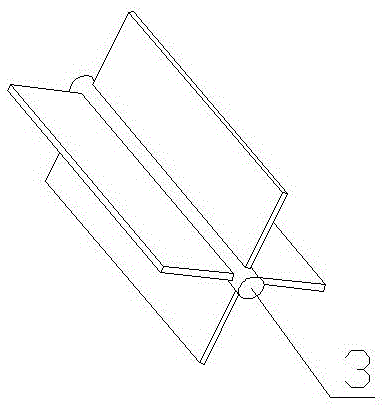

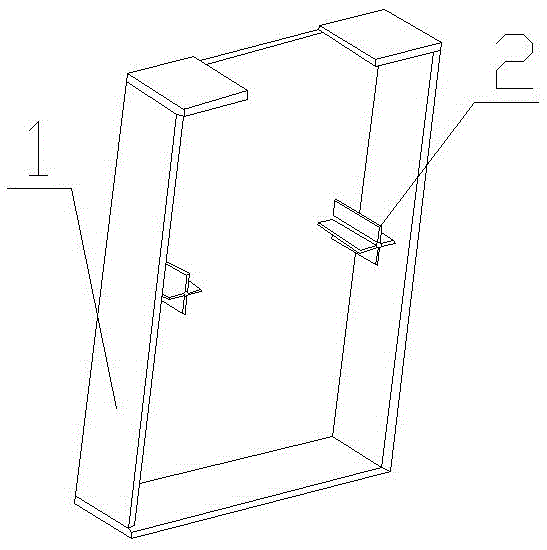

[0135] A liquid anti-sloshing storage box with rotatable cross-shaped blades, which is composed of: a rectangular storage box 1, in which a set of parallel cross-shaped blades 2 are installed, and the rotation axis of the cross-shaped blades 3 is connected to the wall of the storage tank, and the cross-shaped blade is hinged on the rotating shaft.

Embodiment 2

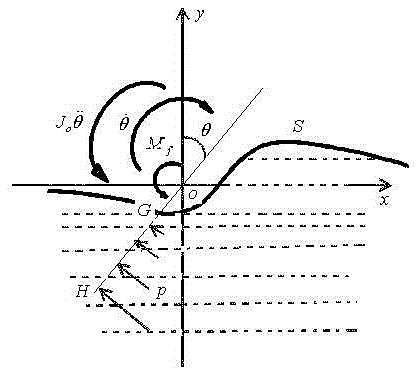

[0137] For the anti-sloshing method of the liquid anti-sloshing tank with rotatable cross-shaped blades, the rotating shaft of the cross-shaped blades is selected as Axis establishes a moving coordinate system ,make The surface is parallel to the free liquid surface in equilibrium, set Moment leaves with The angle between the faces is , Is the free liquid surface, the intersection line of the blade and the free liquid surface is The intersection of the faces is , The boundary line of the leaf and The intersection of the faces is , The leaf length is , The thickness can be ignored, the blade is relatively The moment of inertia of the shaft is , Assuming the angular velocity of the blade rotation or swing Not large enough, the rolling friction moment between the blade bearing and the tank It is proportional to the angular velocity of the blade:

[0138] (1)

[0139] Where: Is the rolling resistance coefficient;

[0140] Assuming that the rigid storage tank remains stat...

Embodiment 3

[0165] According to the anti-sloshing method of the liquid anti-sloshing storage tank with rotatable cross-shaped blades described in the second embodiment, the law of liquid movement in the tank with the cross-shaped blade structure that can rotate around the fixed axis in the liquid-filled rigid body is adjusted. The water wave theory of the constant-deep water body in a liquid rigid tank is, assuming that the liquid-filled rigid body tank is a rectangular tank, the rigid body is stationary, and the free surface of the liquid at the initial moment is , The liquid shook slightly after being slightly disturbed in a certain fluid area, The free surface of the liquid at moment is , The length of the rectangular tank is , The filling height is , The relative liquid velocity component in the thickness direction of the tank is equal to zero, the liquid in the tank can be simplified to a two-dimensional motion problem;

[0166] The liquid in the tank satisfies the Laplace equation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com