Design method of grease lubrication for spherical pair of automobile spherical hinge

A design method and technology of spherical pair, applied in mechanical equipment, vehicle components, steering mechanisms, etc., can solve the problems of large starting torque of automobile spherical joints, inability to meet requirements, and reduced durability and reliability, so as to reduce starting torque and optimize contact. Stress, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

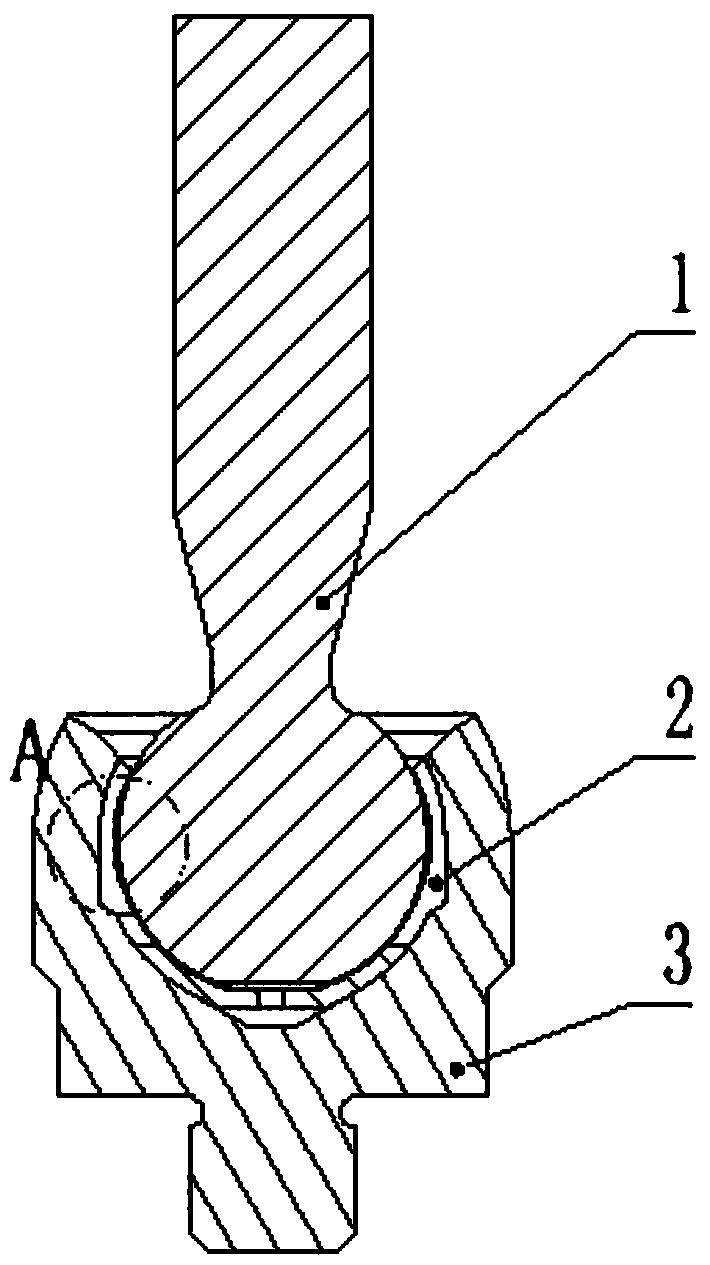

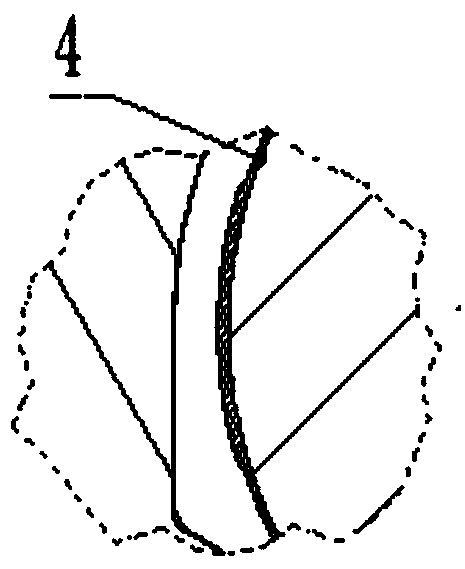

[0051] This embodiment provides a design method for the auxiliary grease lubrication of the spherical surface of the automobile spherical joint, please refer to figure 1 , the ball pin seat 2 is a POM injection molded part, the inner spherical model roughness Ra=0.1μm, the inner spherical surface roughness of the ball pin seat 2 is 1-2 grades lower than the model, so the inner spherical surface Ra of the ball pin seat 2 1 = 0.2μm, Rq 1 =1.25*0.2=0.25, h min = 1 μm.

[0052] substitute Get the root mean square deviation Rq of the profile of the spherical surface of ball pin 1 2 =0.22μm, further get ball pin 1 spherical surface Ra 2 =Rq 2 / 1.25=0.17 μm.

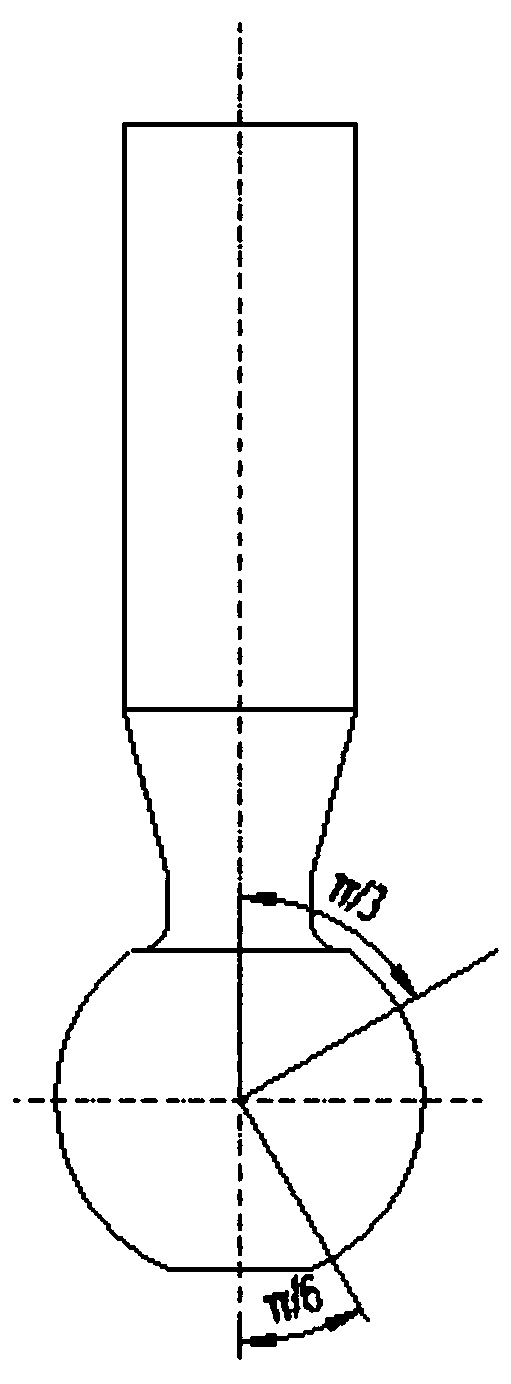

[0053] Establishing the Engineering Calculation Formula M of Spherical Joint Swing Moment f =μ·f·f v ·G·r, swing working moment M f Requires 2.0Nm, axial force G according to G=σ s S' calculation.

[0054] Among them, the ball pin sleeve 3 is made of 20# steel, and its σ s is 245MPa, and the outer diameter before r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com