Feeding belt conveyor with baffle mechanism

A baffle mechanism and belt conveyor technology, applied in mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of uneven cutting, troublesome adjustment of baffles, easy damage, etc., and achieve reliable and highly convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

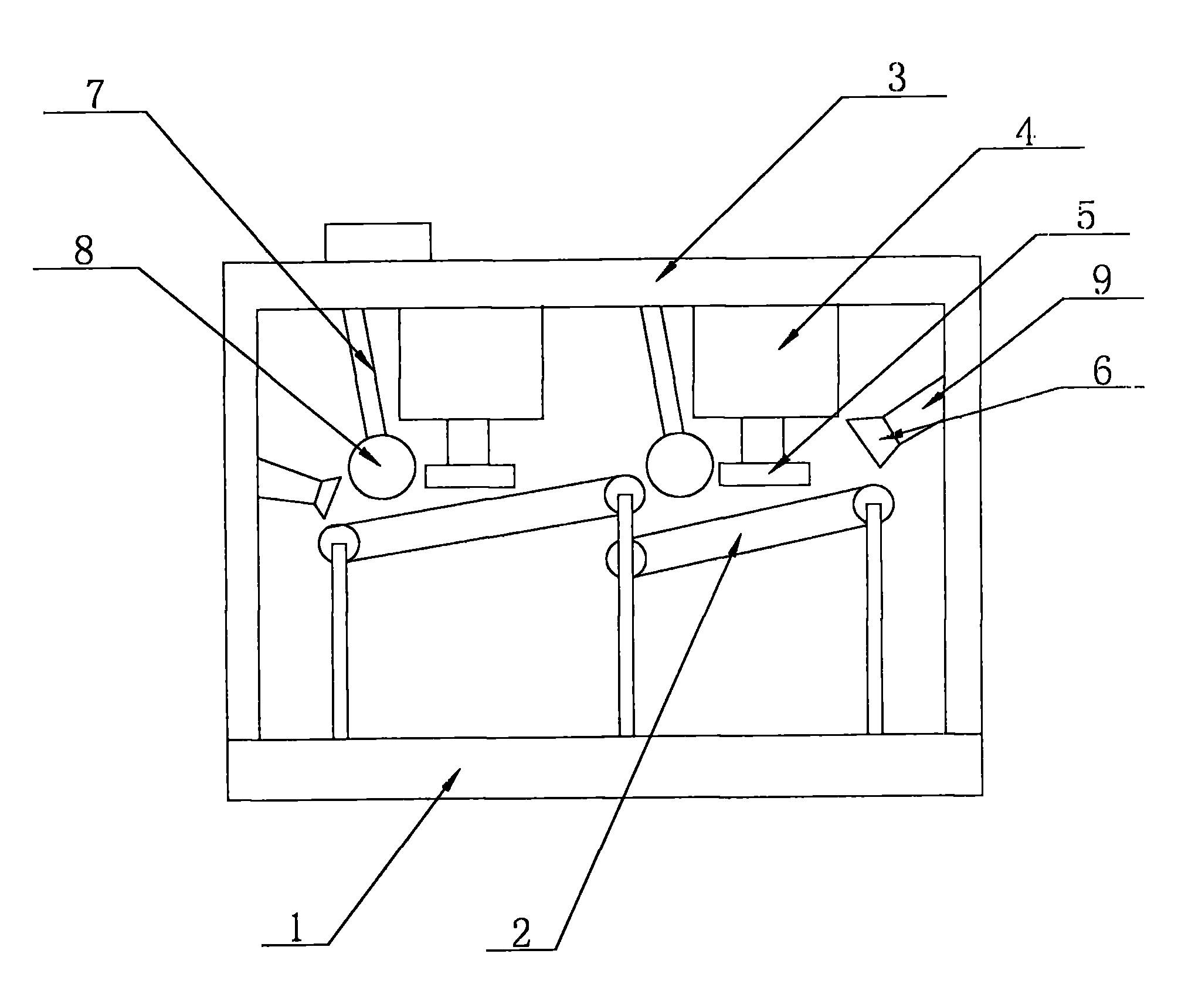

[0012] See attached figure 1 , a feeding belt conveyor with a baffle mechanism disclosed in the present invention, comprising a support 1, a multi-section conveyor belt 2 arranged on the support 1, the support 1 is provided with a cylinder frame 3, and the cylinder frame 3 is A cylinder 4 corresponding to the conveyor belt 2 is provided, and a baffle 5 corresponding to the conveyor belt 2 is provided on the cylinder 4, and a mirror mechanism for reflecting the distance between the baffle 5 and the working surface of the conveyor belt 2 is provided near the baffle 5 The two sides of the cylinder frame 3 are respectively provided with lighting lamps 6 , and the lighting lamps 6 are all arranged towards the direction of the working surface of the conveyor belt 5 .

[0013] The mirror mechanism includes a connecting rod 7 and a mirror 8, one end of the connecting rod 7 is fixedly connected to the upper end of the cylinder frame 3, the other end of the connecting rod 7 extends to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com