A Method for Direct Preparation of Micro-arc Oxidation Ceramic Membrane Containing Hydroxyapatite

A technology of hydroxyapatite and micro-arc oxidation, which is applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of poor biocompatibility of ceramic films on the surface of titanium alloys, and promote early growth, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

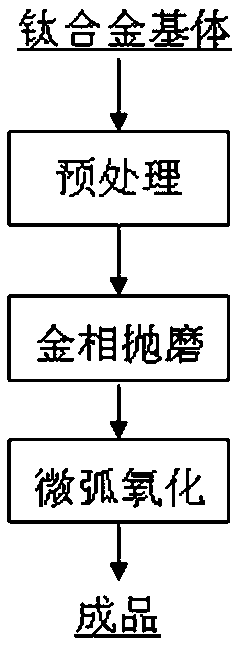

Image

Examples

Embodiment 1

[0025] A. Pretreatment of titanium alloy samples: the titanium alloy Ti 6 al 4 V is cut into a cylindrical titanium material, and a hole is drilled on the top of the sample; the surface of the titanium alloy is polished until there are no obvious scratches on the surface of the sample, and then degreased with ethanol, 1g / L sodium hydroxide solution, and alkali-washed. Wash with deionized water and dry naturally;

[0026] B. Micro-arc oxidation: Suspend the cylindrical titanium material after the aforementioned treatment in the electrolyte for micro-arc oxidation; the power supply used is a pulse power supply, and the power supply parameters are set as: voltage 450V, duty cycle 30%, frequency The frequency is 900Hz, the number of positive pulses is 1, the number of negative pulses is 1, and the oxidation time is 15min. The electrolyte is prepared as follows: calcium acetate 0.15mol / L, disodium EDTA 0.15mol / L, potassium dihydrogen phosphate 0.1mol / L.

[0027] C. Post-treatmen...

Embodiment 2

[0029] A. Pretreatment of titanium alloy samples: the titanium alloy Ti 6 al 4 V is cut into a cylindrical titanium material, and a hole is drilled on the top of the sample; the surface of the titanium alloy is polished until there are no obvious scratches on the surface of the sample, and then degreased with ethanol, 1g / L sodium hydroxide solution, and alkali-washed. Wash with deionized water and dry naturally;

[0030] B. Micro-arc oxidation: Suspend the cylindrical titanium material after the aforementioned treatment in the electrolyte for micro-arc oxidation; the power supply used is a pulse power supply, and the power supply parameters are set as: voltage 475V, duty cycle 40%, frequency The frequency is 900Hz, the number of positive pulses is 1, the number of negative pulses is 1, and the oxidation time is 20min. The electrolyte solution is prepared as follows: calcium acetate 0.2mol / L, disodium EDTA 0.15mol / L, potassium dihydrogen phosphate 0.1mol / L.

[0031] C. Post-...

Embodiment 3

[0033] A. Pretreatment of titanium alloy samples: the titanium alloy Ti 6 al 4 V is cut into a cylindrical titanium material, and a hole is drilled on the top of the sample; the surface of the titanium alloy is polished until there are no obvious scratches on the surface of the sample, and then degreased with ethanol, 1g / L sodium hydroxide solution, and alkali-washed. Wash with deionized water and dry naturally;

[0034] B. Micro-arc oxidation: Suspend the cylindrical titanium material after the aforementioned treatment in the electrolyte for micro-arc oxidation; the power supply used is a pulse power supply, and the power supply parameters are set as: voltage 450V, duty cycle 40%, frequency The frequency is 900Hz, the number of positive pulses is 1, the number of negative pulses is 1, and the oxidation time is 20min. The electrolyte is prepared as follows: calcium acetate 0.15mol / L, disodium EDTA 0.15mol / L, potassium dihydrogen phosphate 0.1mol / L.

[0035] C. Post-treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com