A method of using formamide-double metal hydroxide as concrete early strength agent

A hydroxide, formamide technology, applied in the field of concrete early strength agent, formamide-double metal hydroxide, double metal hydroxide, can solve the problems of reduced early strength performance, LDH nanosheet aggregation, etc. Early strength, early growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete processing steps of the present embodiment are:

[0020] (1), Mg(NO 3 ) 2 and Al(NO 3 ) 3 Dissolve in 50ml of deionized water to prepare a mixed salt solution with a total concentration of metal ions of 0.2mol / l; the ratio of the amount of Mg to Al is 2:1; prepare 50ml of ammonia solution with a mass concentration of 7%;

[0021] (2), using the common co-precipitation method, drop the ammonia solution into the mixed salt solution, and fully stir for 30 minutes; the reaction temperature is 30°C;

[0022] (3) Continue stirring the precipitate at 30°C for 2 hours, centrifuge at 8000rpm for 3 minutes, wash with deionized water and dry at 60°C;

[0023] (4) Take 1 g of dried LDH and disperse it in 15 mL of formamide, observe and observe a gel-like substance after ultrasonication for 30 minutes;

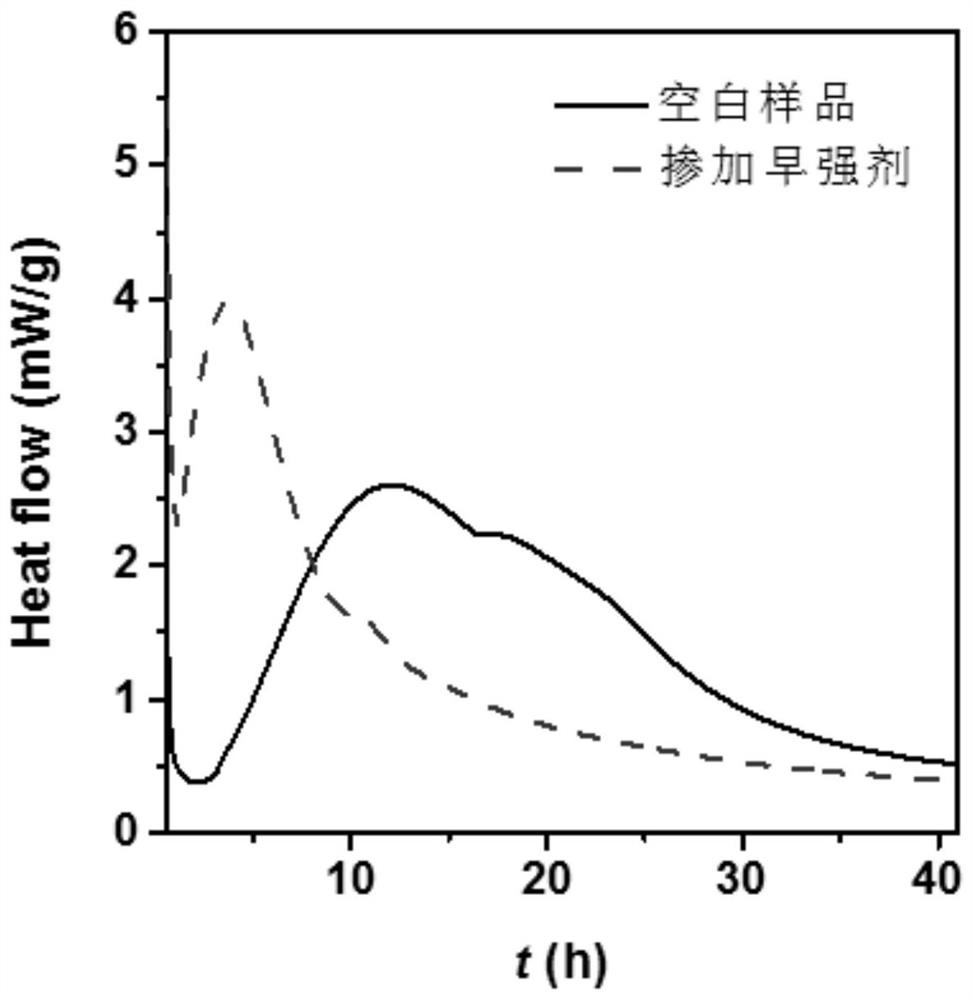

[0024] (5) Take 0.32g of the above-mentioned LDH formamide stripped product and 1.44g of water for 3 minutes, then add 4g of ordinary Portland cement P.O.42.5 and ...

Embodiment 2

[0028] The concrete processing steps of the present embodiment are:

[0029] (1), Mg(NO 3 ) 2 and Al(NO 3 ) 3 Dissolve in 50ml of deionized water to prepare a mixed salt solution with a total concentration of metal ions of 1.0mol / l; the ratio of the amount of Mg to Al is 2:1; prepare 50ml of ammonia solution with a mass concentration of 7%;

[0030] (2), using the common co-precipitation method, drip the ammonia solution into the mixed salt solution, and fully stir for 30 minutes; the reaction temperature is 25 ° C;

[0031] (3), continue to stir the precipitate at 40°C for 2 hours, centrifuge at 8000rpm for 3 minutes, wash with deionized water and dry at 60°C;

[0032] (4) Take 1 g of dried MgAl-LDH and disperse it in 15 mL of formamide, observe and find a gel-like substance after ultrasonication for 30 minutes;

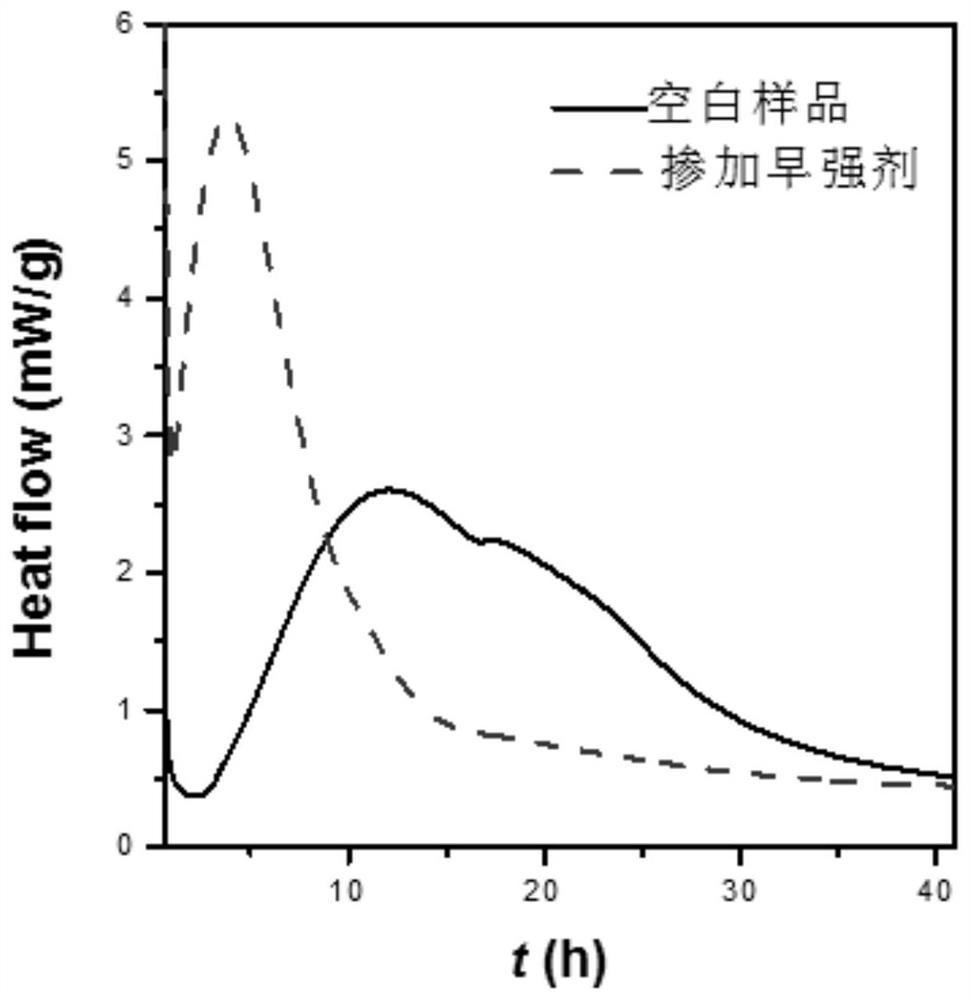

[0033] (5) Take 0.32g of the above-mentioned MgAl-LDH formamide stripped product and 1.44g of water for ultrasonication for 3 minutes, then add 4g of ordinary ...

Embodiment 3

[0037] (1), Mg(NO 3 ) 2 and Al(NO 3 ) 3 Dissolve in 50ml of deionized water to prepare a mixed salt solution with a total concentration of metal ions of 0.2mol / l; the ratio of the amount of Mg to Al is 3:1; prepare 50ml of ammonia solution with a mass concentration of 7%;

[0038] (2), using the common co-precipitation method, drop the ammonia solution into the mixed salt solution, and fully stir for 30 minutes; the reaction temperature is 30°C;

[0039] (3) Continue stirring the precipitate at 160°C for 2 hours, centrifuge at 8000rpm for 3 minutes, wash with deionized water and dry at 60°C;

[0040] (4) Take 1 g of dried LDH and disperse it in 30 mL of formamide, observe and observe a gel-like substance after ultrasonication for 30 minutes;

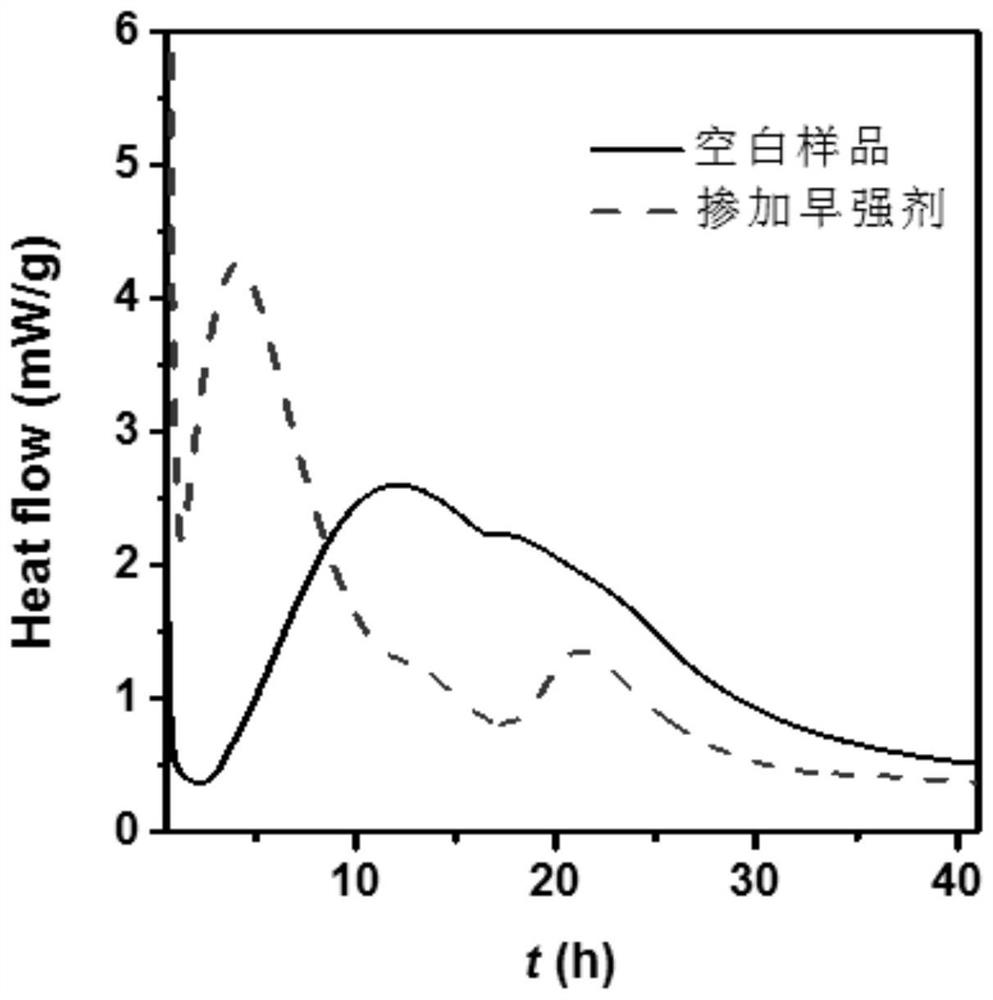

[0041] (5) Take 0.96g of the above-mentioned LDH formamide stripped product and 0.80g of water for ultrasonication for 3 minutes, then add 4g of ordinary Portland cement P.O.42.5 and mix well;

[0042] (6), the mixture in (5) is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com