Curtain Wall System

A curtain wall and curtain wall panel technology, which is applied in the field of curtain wall systems, can solve problems such as broken glass panels, glass panels falling, and glass panels moving, and achieve the effects of simple structure, convenient installation, and improved integrity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

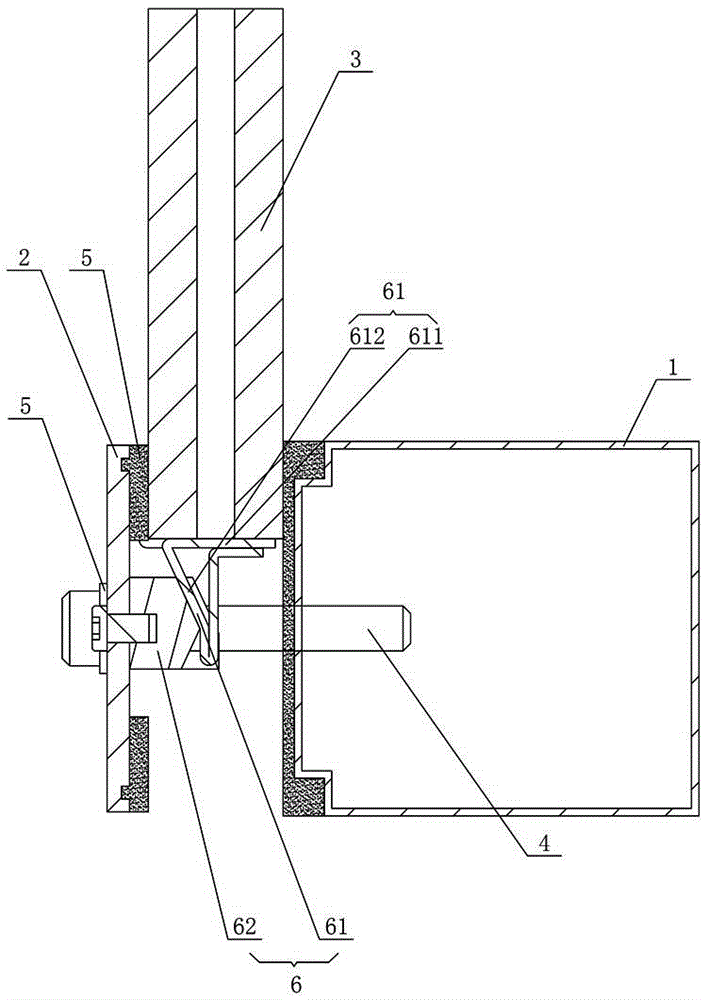

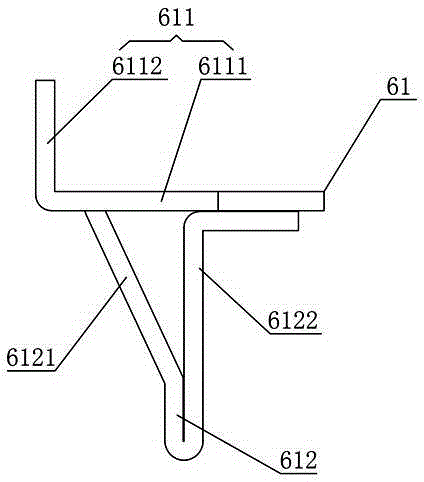

[0034] Figure 1 to Figure 6 The first embodiment of the curtain wall system of the present invention is shown, the curtain wall system includes a keel 1, a pressing plate 2 and a curtain wall panel 3, and the curtain wall panel 3 is clamped between the keel 1 and the pressing plate 2 by a fastener 4 , the two sides of the curtain wall panel 3 and / or between the fastener 4 and the pressure plate 2 are provided with a thermal insulation 5, the thermal insulation 5 can play the effect of breaking bridge heat insulation, its structure is simple, easy to install, and the keel 1 and the pressure plate 2 is installed with a driving and pressing device 6 for driving the curtain wall panel 3 to move to the keel 1 under the action of gravity of the curtain wall panel 3 when the heat insulating part 5 fails and disappears, and to press it against the keel 1. When the curtain wall When the thermal insulation 5 in the system is melted at the same time under high temperature, there will be...

Embodiment 2

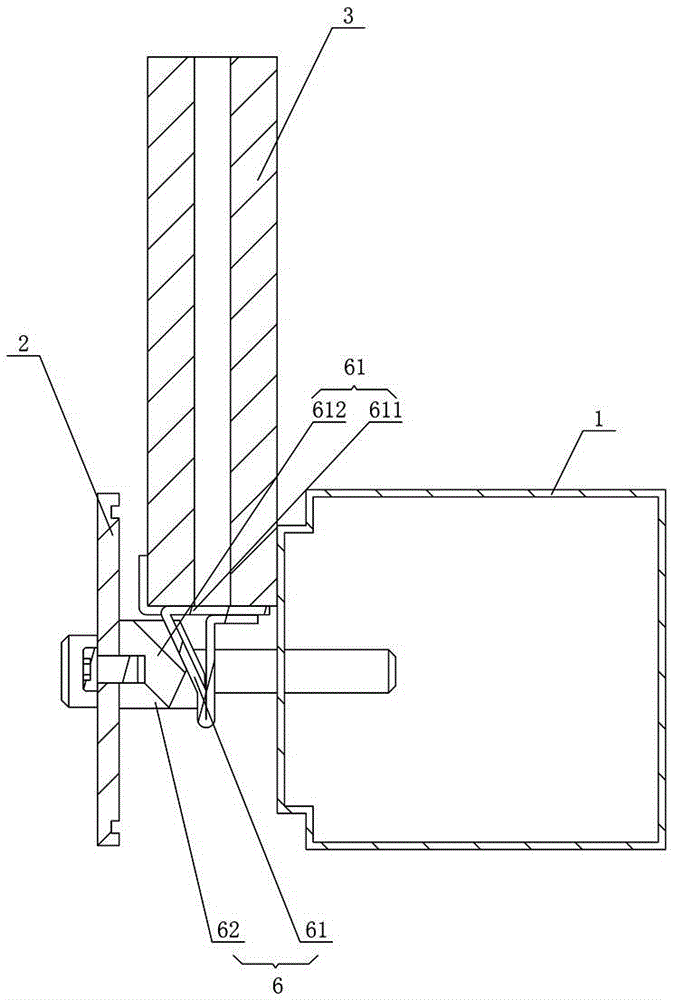

[0042] Figure 7 to Figure 11 It shows the second embodiment of the curtain wall system of the present invention, the curtain wall system is basically the same as that of Embodiment 1, the only difference is that the coupling part 612 is hinged with the limiter 62, and the two sides of the limiter 62 are hinged with locking blocks 624 The coupling part 612 is provided with a locking tooth 6123 that cooperates with the locking block 624. When the driving part 61 is subjected to the gravity of the curtain wall panel 3 falling, the coupling part 612 and the limiting part 62 form a rotation around the hinge point. , so the connecting part 612 will rotate along the limiter 62 and drive the push edge 6112 to drive the curtain wall panel 3 to move to the keel 1 and press on the keel 1, and then the locking block 624 will be locked and locked with the locking tooth 6123 to realize the alignment The entire driving member 61 is locked, and its structure is simple and easy to implement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com