Low-resistance synchronous ring and synchronizer

A synchronous ring, low resistance technology, used in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of errors, affecting the uniformity of the synchronous ring force, obstacles, etc., to reduce the contact area, reduce resistance, and ensure uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

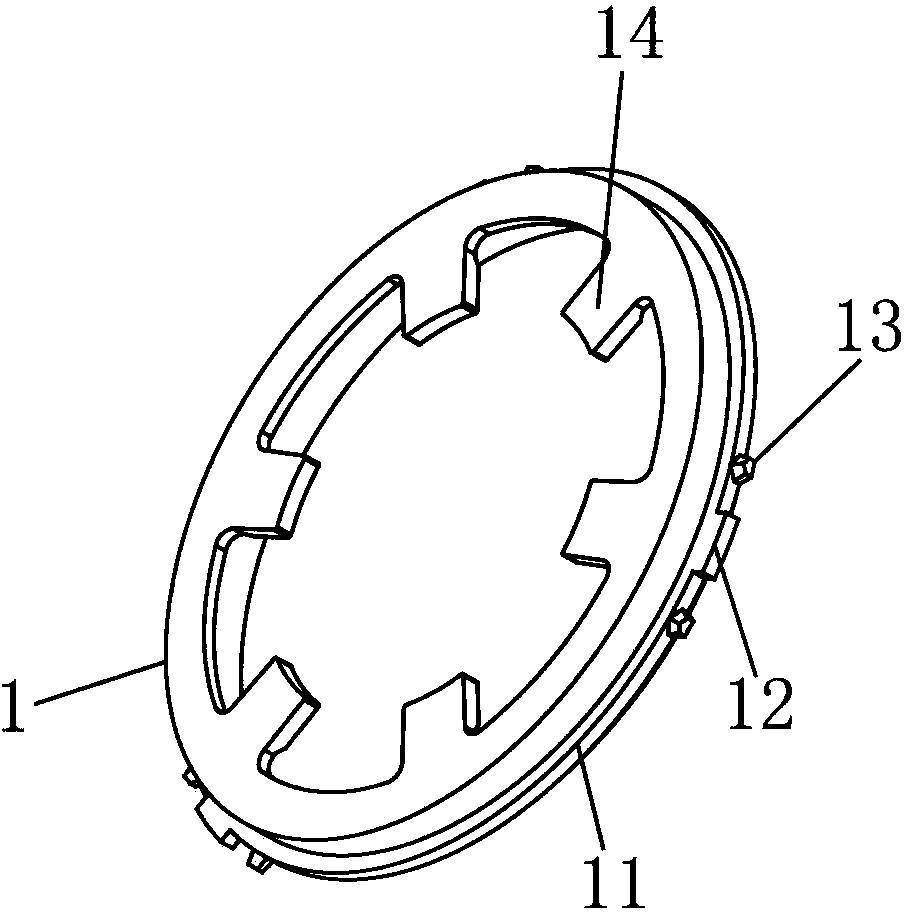

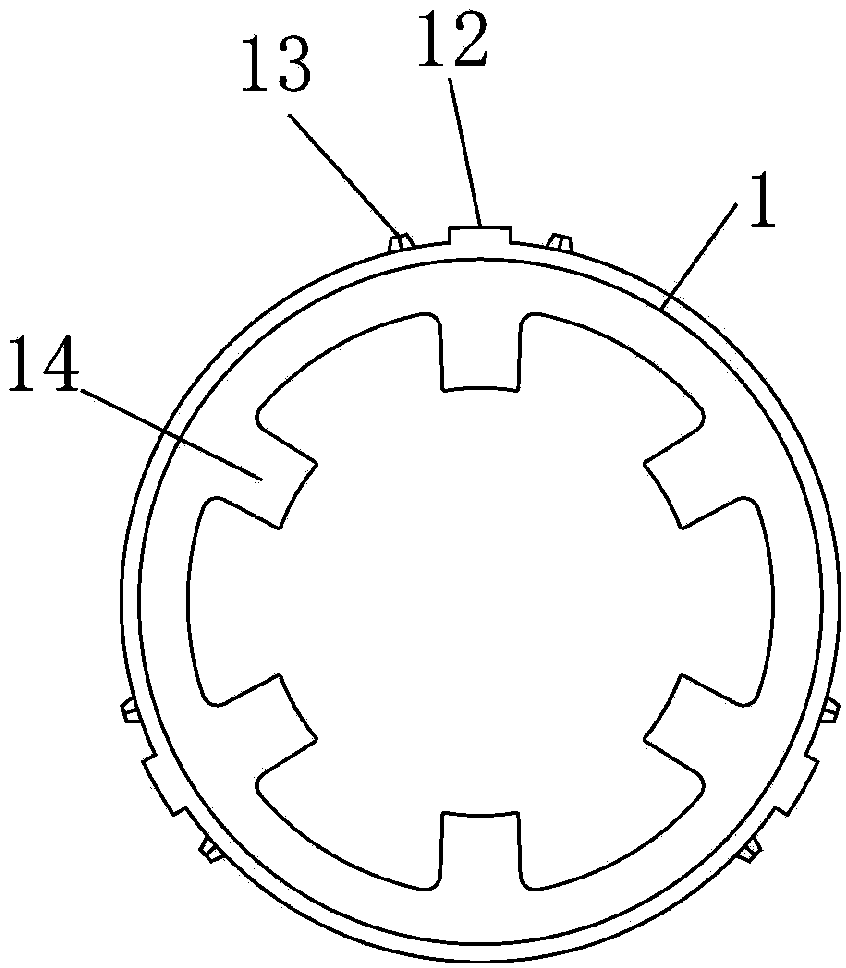

[0021] The specific embodiments created by the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The design idea created by the present invention is to change the existing design idea of completing synchronization and locking by controlling the multiple spline tooth directions in the gear sleeve to complete the synchronization and locking by sliding in the tooth grooves between the multiple coupling teeth on the synchronizing ring that matches it. , Changed to control the combination tooth on the synchronizing ring to slide in the tooth groove between the spline teeth in the gear sleeve to complete synchronization and lock. Although the essence is the relative sliding of the synchronizer ring and the gear sleeve, it can be concluded from this idea that reducing the number of coupling teeth not only can still ensure the stability of shifting, but also because of the multiple spline teeth and multiple coupling teeth. The hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com