Patents

Literature

96results about How to "Realize the locking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

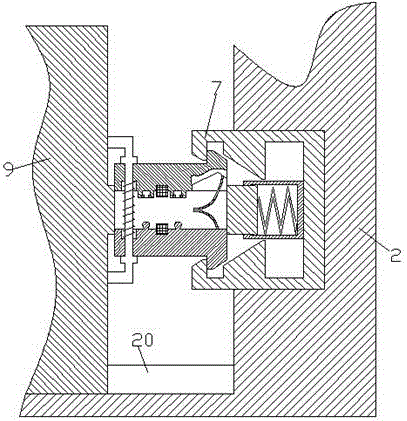

Power component locking device of power cabinet

InactiveCN105722365AEven by forceRealize the locking effectClamping/extracting meansPower componentEngineering

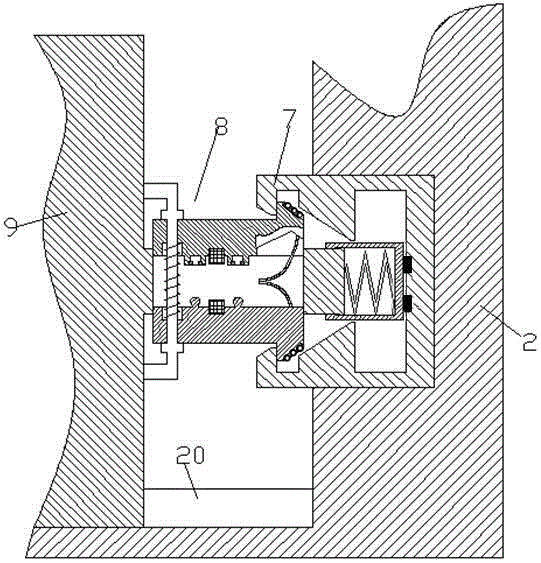

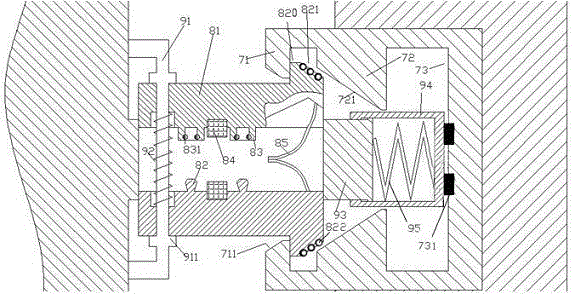

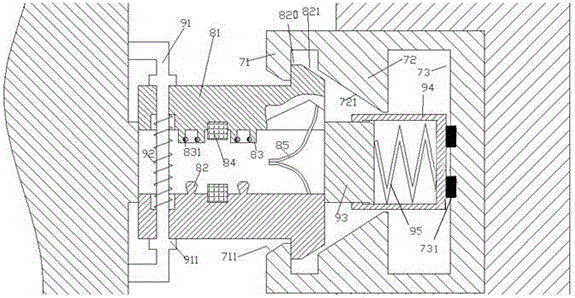

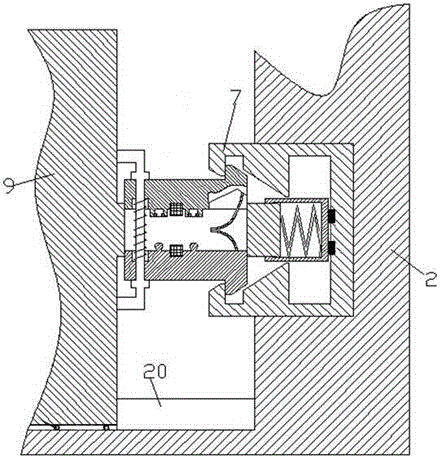

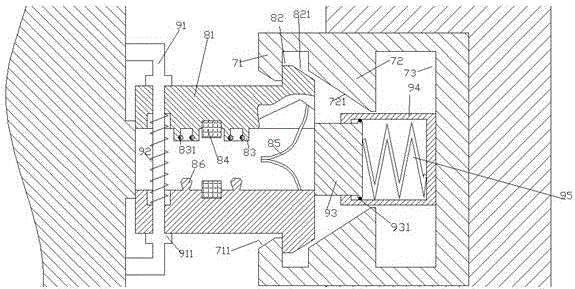

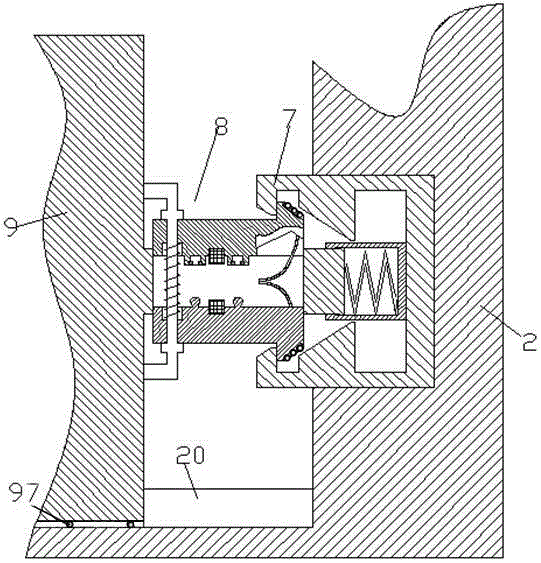

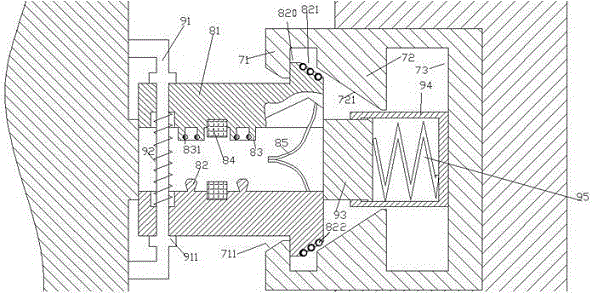

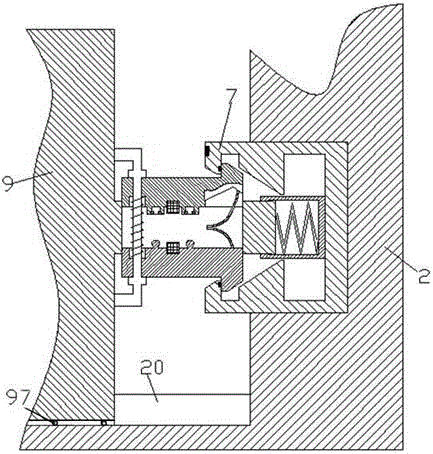

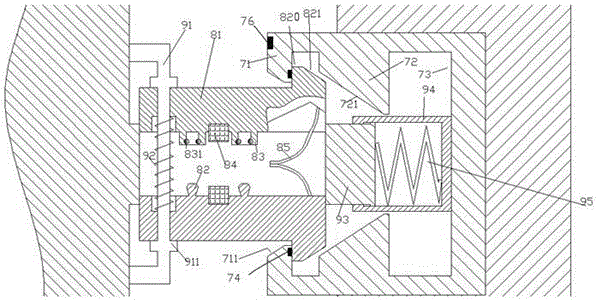

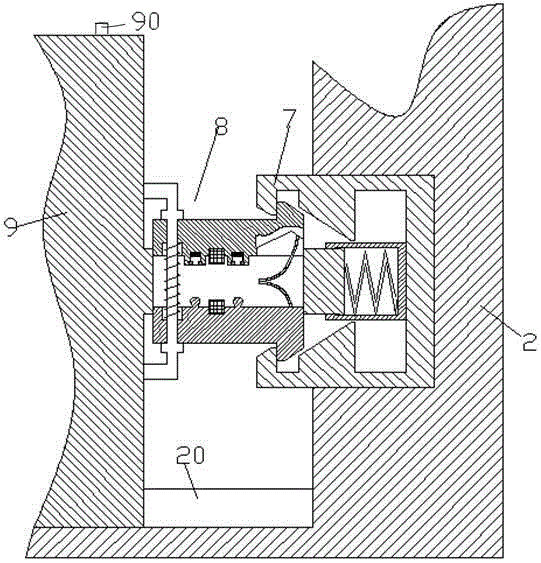

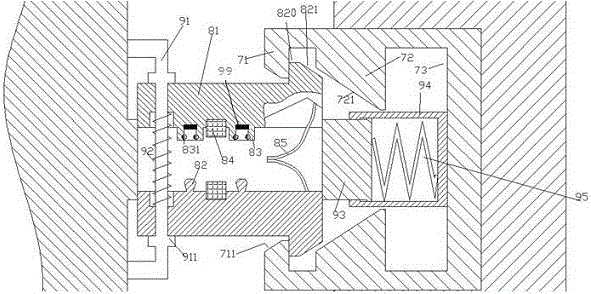

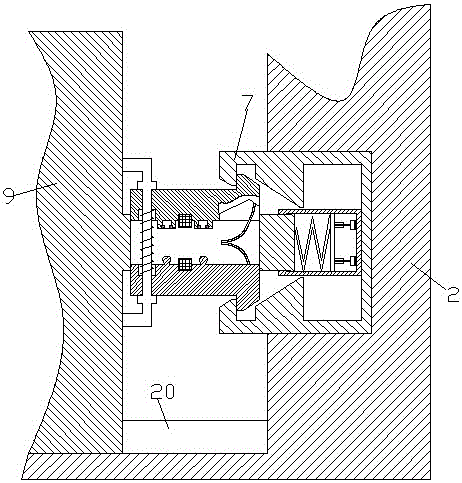

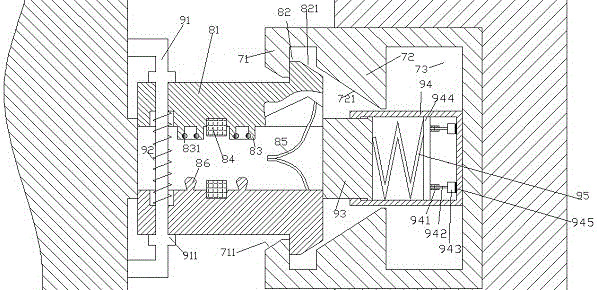

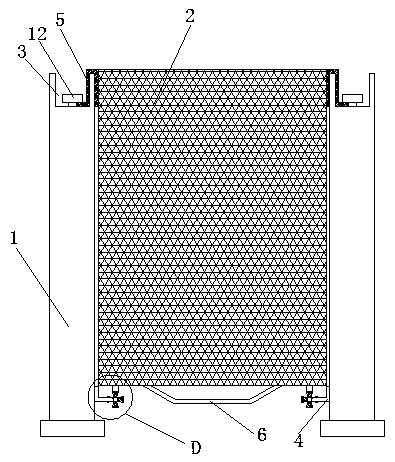

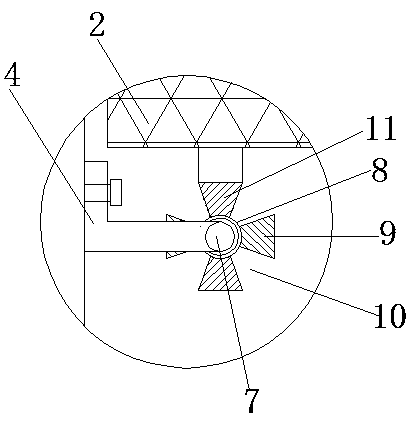

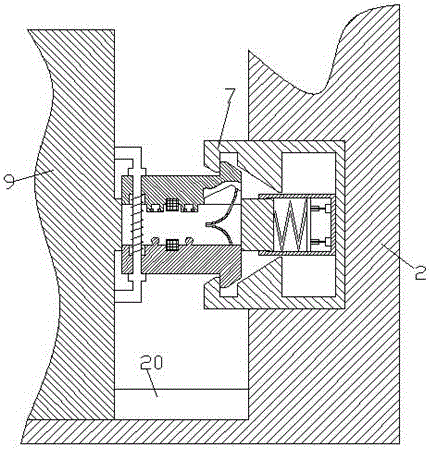

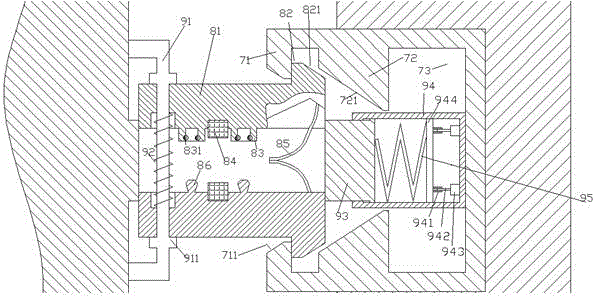

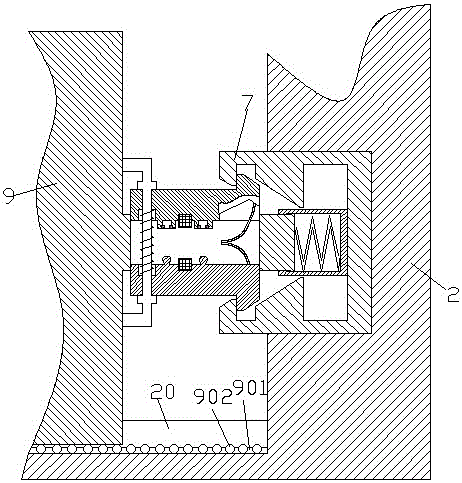

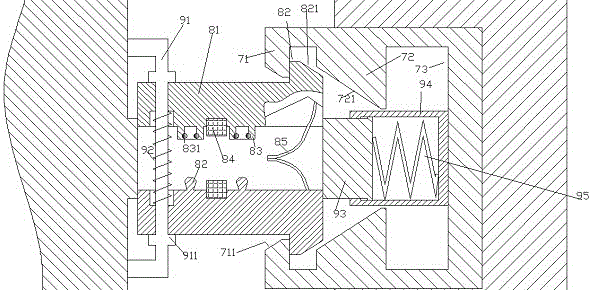

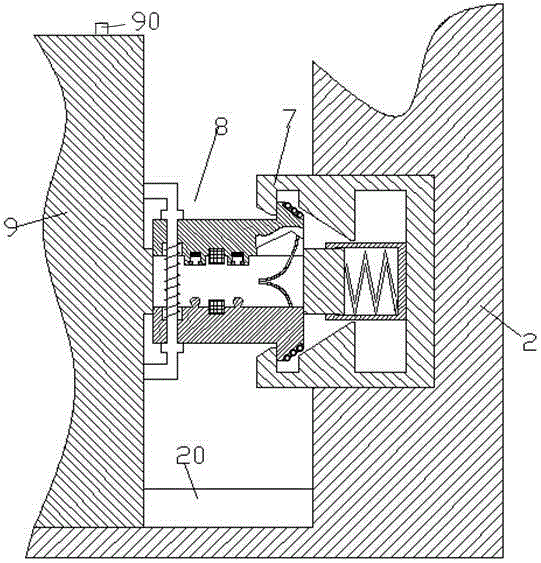

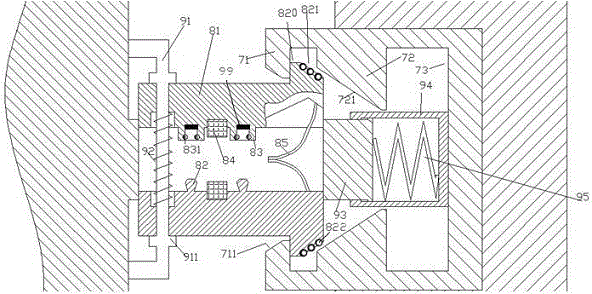

The invention discloses a power component locking device of a power cabinet. The device comprises an electrical cabinet body (2) with a horizontal track (20) and a power component (9) capable of sliding on the horizontal track (20); a locking and unlocking embedding element (7) is fixedly arranged on the vertical rear wall of the electrical cabinet body (2); wherein a lug boss (93) which is used for stretching into the cavity of the locking and unlocking embedding element (7) is fixedly arranged on the power component (9); a sliding cavity is arranged in the lug boss (93); and two locking sliding wedge blocks (81) are mounted in the sliding cavity symmetrically in a sliding mode.

Owner:BIWANGJIA MECHANICAL TECH SHENZHEN CO LTD

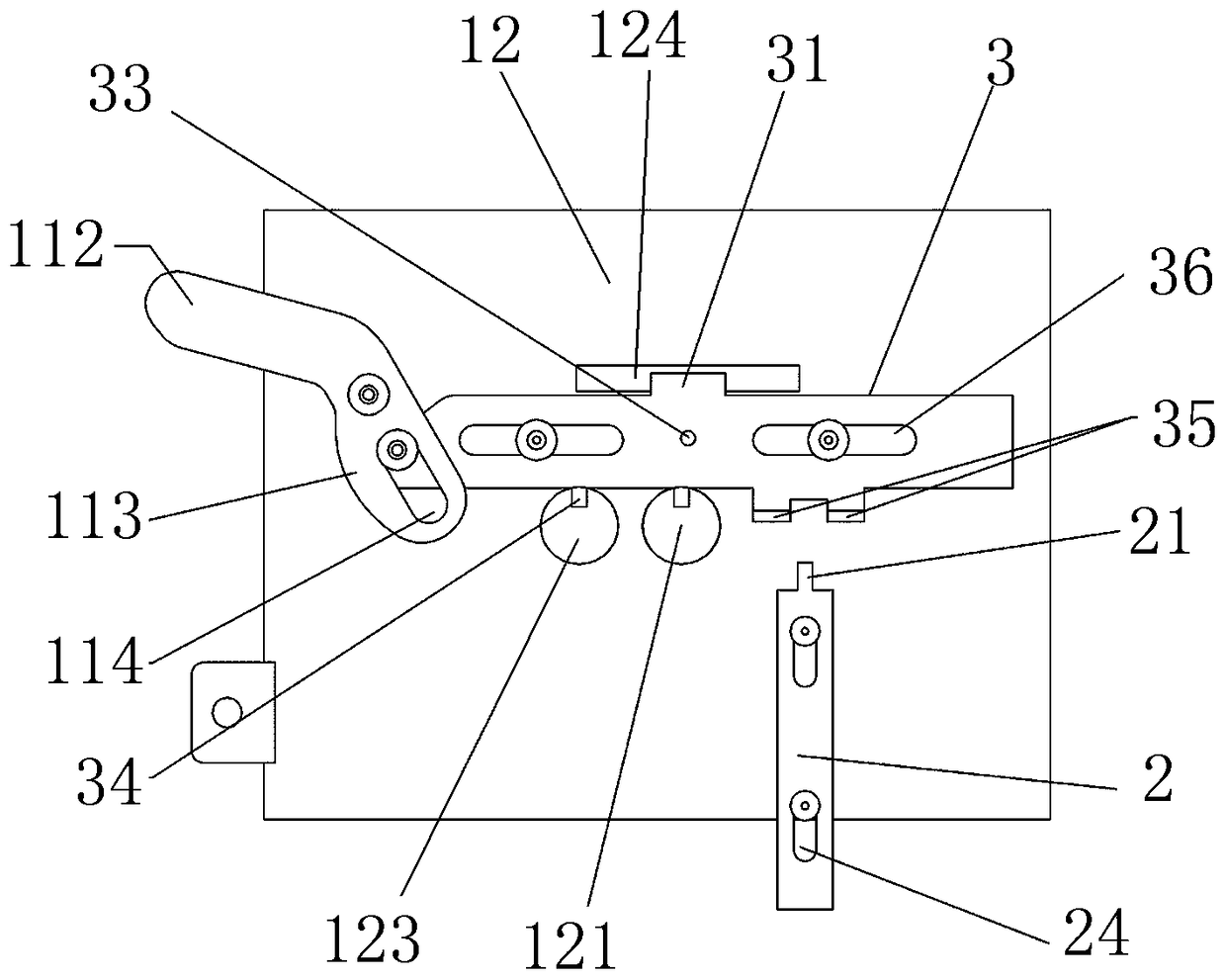

Switch cabinet and interlocking device used for isolation switch and circuit breaker of switch cabinet

PendingCN108320946AAvoid misuseWill not increase the burdenElectric switchesLocking mechanismEngineering

The invention relates to a switch cabinet and an interlocking device used for the isolation switch and the circuit breaker of the switch cabinet. The interlocking device comprises a flexible push plate, a button locking structure and a flexible push plate locking mechanism which is arranged between the operation shaft of the flexible push plate and the circuit breaker. The flexible push plate is provided with a shielding operation hole and an initial position corresponding to the closed circuit breaker and an avoidance operation hole and an avoidance position corresponding to the separated circuit breaker. The button locking structure and the flexible push plate are connected through a transmission structure so that the button locking structure is driven to lock the closing button when theflexible push plate moves to the avoidance position from the initial position and the button locking structure is driven to perform unlocking when the flexible push plate recovers to the initial position. The flexible push plate locking mechanism locks the flexible push plate at the initial position when the circuit breaker is closed and unlocks the flexible push plate when the circuit breaker isseparated. Mechanical interlocking control between the isolation switch and the circuit breaker can be realized so that the structure is simple and operation is convenient without increasing the burden of the isolation switch operation mechanism and the circuit breaker operation mechanism.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Electric device locking component with high security performance

InactiveCN105914587AAchieve lockingControl movement speedSubstation/switching arrangement boards/panels/desksEngineeringMechanical engineering

The invention provides an electric device locking component with a high security performance. The component comprises an electric cabinet body (2) with a horizontal track (20) and a sliding electric component (9) able to slide along the horizontal track (20). The upright back wall of the electric cabinet body (2) is fixedly provided with a locking and unlocking embedded piece (7). The electric component (9) is fixedly provided with a protruding part (93) which extends into the inner cavity of the locking and unlocking embedded piece (7). The protruding part (93) is provided with a sliding cavity, allowing two symmetrically arranged locking and sliding wedges to be mounted therein in a sliding manner.

Owner:QINGDAO HAITENGDA MACHINERY TECH CO LTD

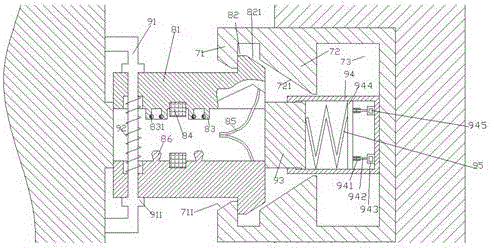

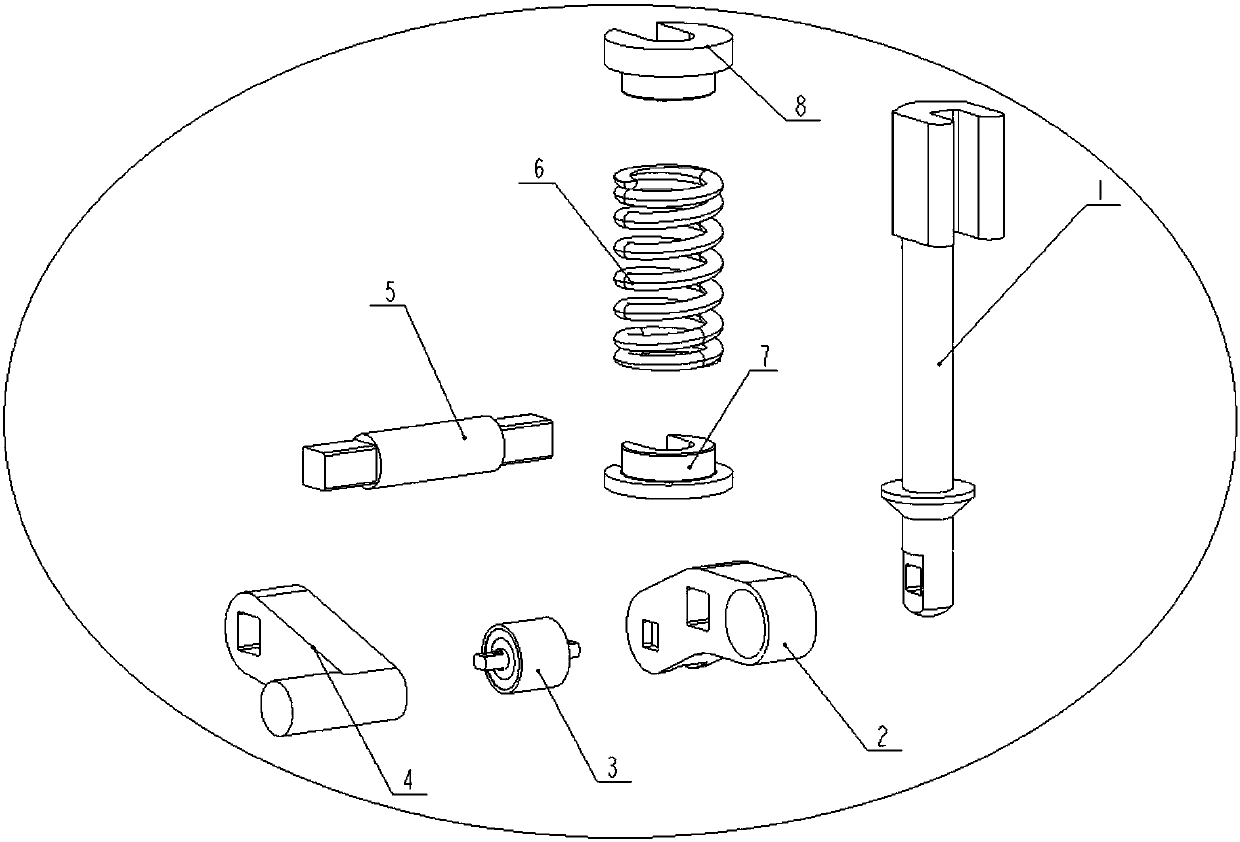

Locking mechanism for gauge-variable bogie of high-speed electric multiple unit

InactiveCN107757651AAchieve unlockRealize the locking effectAxle-boxesDifferent width rail tracksBogieLocking mechanism

A locking mechanism for a gauge-variable bogie of a high-speed electric multiple unit (EMU) comprises a locking rod, a working arm, a joint, a driving arm, a connecting rod, a spring, a lower stop block and an upper stop block, wherein the middle of the working arm is connected to the driving arm by the connecting rod; one end of the working arm is connected to a rotating arm hoop and the other end of the working arm is fixedly connected to the locking rod; the spring is mounted around the locking rod; and the upper end of the locking rod is inserted into an axle box body, an axle box rotatingarm beam and a locking keyway of the rotating arm hoop to realize locking. The locking mechanism for the gauge-variable bogie of the high-speed EMU locks a sliding device which is fixedly connected to the axle box body through the locking rod, so as to realize the function of unlocking and locking wheels by the gauge-variable bogie during the process of adjusting the inner distance of wheelsets.After unlocking the wheels, the locking mechanism ensures that the inner distance of the wheelsets can be freely and flexibly adjusted, and after locking the wheels, the locking mechanism ensures thata train can safely run on fixed-gauge tracks.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

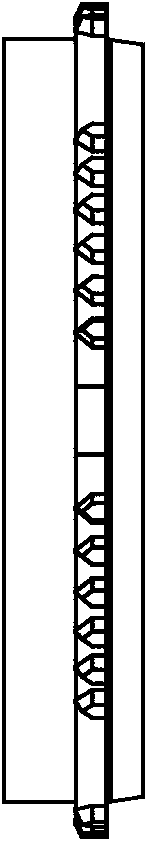

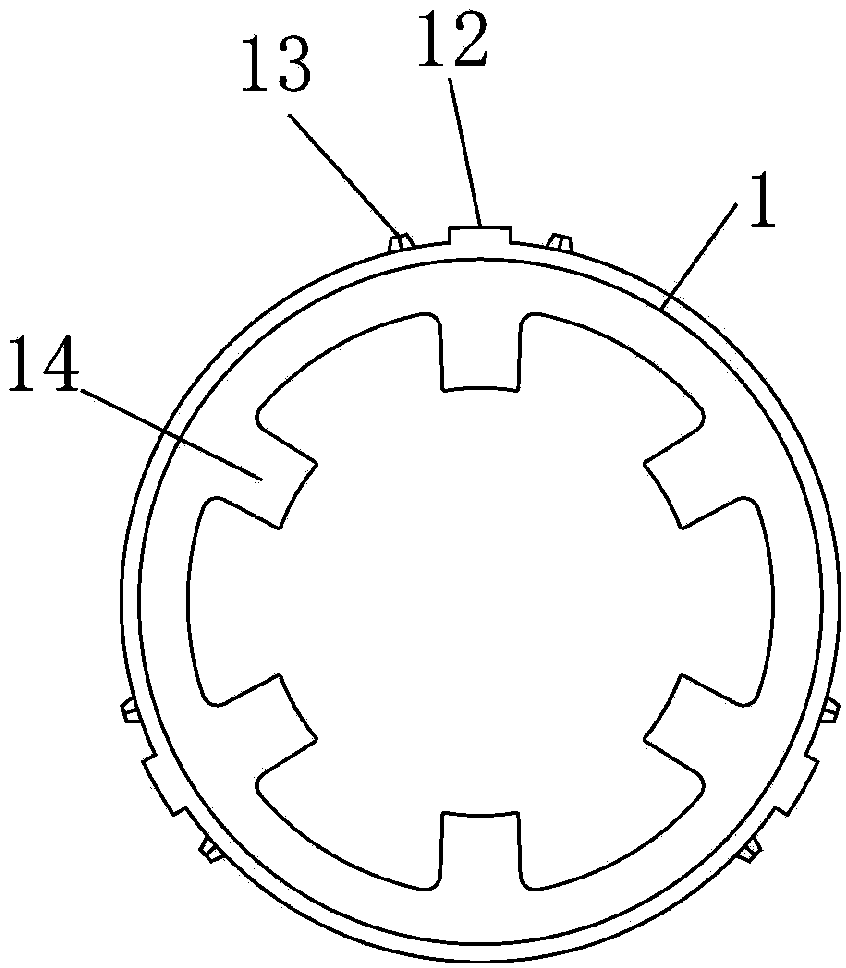

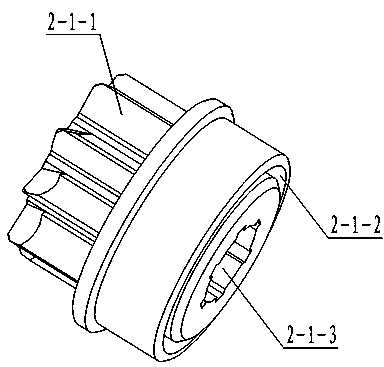

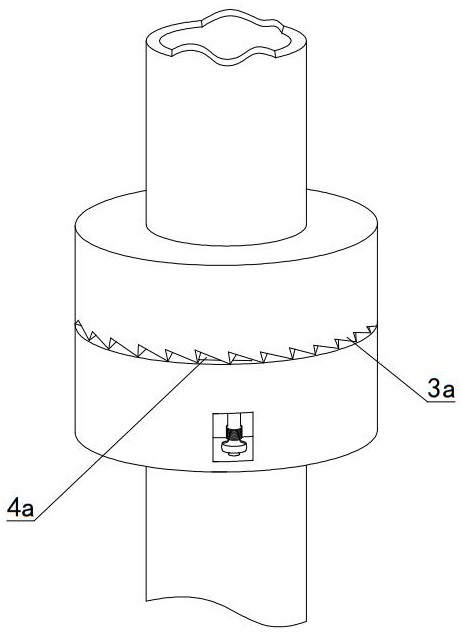

Low-resistance synchronous ring and synchronizer

InactiveCN103899671AReduce shift resistanceAchieve synchronizationMechanical actuated clutchesEngineeringLow resistance

The invention provides a low-resistance synchronous ring comprising a synchronous ring base which is conical and circular. The large diameter end of the synchronous ring base is provided with a flange. The outer periphery of the flange is evenly provided with three spline tooth sets. Each spline tooth set includes a slider push stopper and two connecting teeth; the connecting teeth are peripherally distributed on two sides of the slider push stopper at intervals; the small diameter end of the synchronous ring base is peripherally and evenly provided with jaws extending out of the center axis of the synchronous ring base. A synchronizer with the synchronous ring comprises a toothed sleeve matching with the synchronous ring, a tooth seat and the like. By decreasing the connecting teeth, uniform shifting force is guaranteed, area of contact of the connecting teeth with internal spline teeth of the toothed sleeve is reduced, extra resistance is decreased in the shifting process, the whole synchronous ring is evenly stressed, the synchronous ring can be used without changing other parts, and the shifting process is easier and smoother.

Owner:天津天海同步科技有限公司

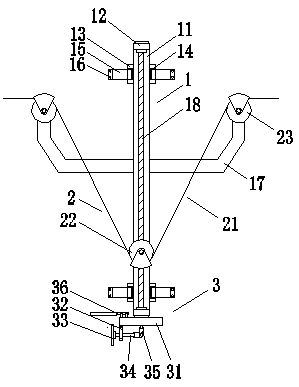

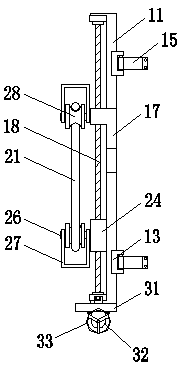

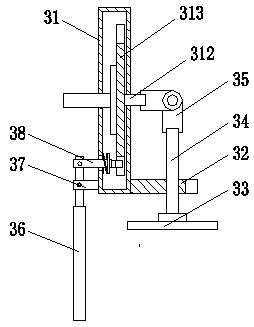

Electric power construction stringing device

InactiveCN110797801AAvoid bruisesAvoid breakingApparatus for overhead lines/cablesScrew threadThreaded rod

The invention discloses an electric power construction stringing device. The device comprises a stringing frame, a stringing mechanism and a locking mechanism, wherein the stringing mechanism is installed on one side of the stringing frame, the locking mechanism is installed at a lower end of the stringing frame, the stringing mechanism is connected with the locking mechanism, the stringing framecomprises a vertical plate, blocking supports, hinge seats, rotating pins, binding belts, positioning holes, extension rods and threaded rods, and an upper end and a lower end of one side of the vertical plate are fixedly connected with the blocking supports. The power construction stringing device is advantaged in that stringing frame hoops are sleeved on outer walls of electric power laying rods, the stringing degree is adjusted by the stringing mechanism, the locking effect is realized by the locking mechanism, the structure is reasonable, operation is simple, compared with a traditional construction stringing device, the power construction stringing device not only has the stringing effect, but further can realize gradual wire loosening operation in an unlocked state, so a problem of cable drawing damage or snapping caused by sudden loosening of the cable is avoided, and a wire pulling facility does not need to be additionally arranged.

Owner:YANTAI MUPING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

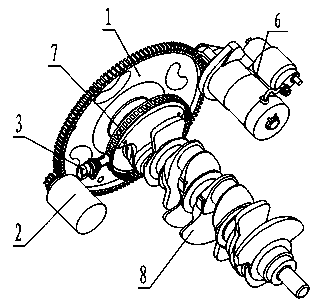

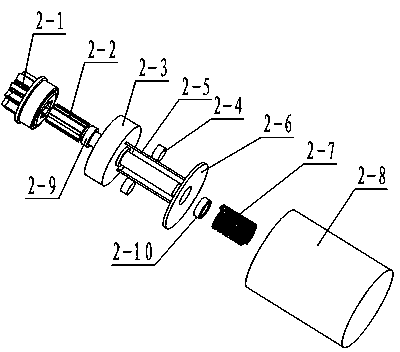

Crankshaft position limiting system after flameout of automobile engine

ActiveCN103388527AImprove dynamic responsivenessReduce fuel consumptionMachines/enginesEngine componentsLocking mechanismDrive shaft

The invention relates to a crankshaft position limiting system after flameout of an automobile engine, aiming at solving the problem that the engine cannot be quickly started up. The crankshaft position limiting system comprises an engine flywheel, a crankshaft position locking mechanism, a crankshaft position sensor, a crankshaft signal panel and an ECU (Engine Control Unit). The crankshaft position locking mechanism comprises a locking gear, a transmission shaft, a locking wheel, an electromagnetic valve, a traction pushrod, a traction disc, a return spring and an engine body shell. The locking gear is installed at the front end of the transmission shaft. The transmission shaft is assembled with the locking wheel. The electromagnetic valve is arranged at the front of the traction disc. The traction disc is fixedly assembled with the rear end of the traction pushrod. The front end of the traction pushrod penetrates through the locking wheel and then is assembled with the locking gear. The return spring is sheathed in the inner chamber of the engine body shell. The crankshaft position limiting system after the flameout of the automobile engine has the characteristics of simple structure and stable performance, the improvement of quick response performance of vehicle power is facilitated, the engine can be flamed out when the vehicle is stopped for waiting, and not only can the oil consumption of the vehicle be reduced, but also the emission of tail gas can be reduced.

Owner:GREAT WALL MOTOR CO LTD

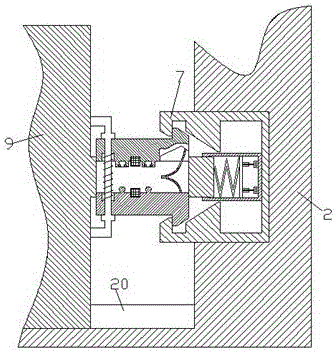

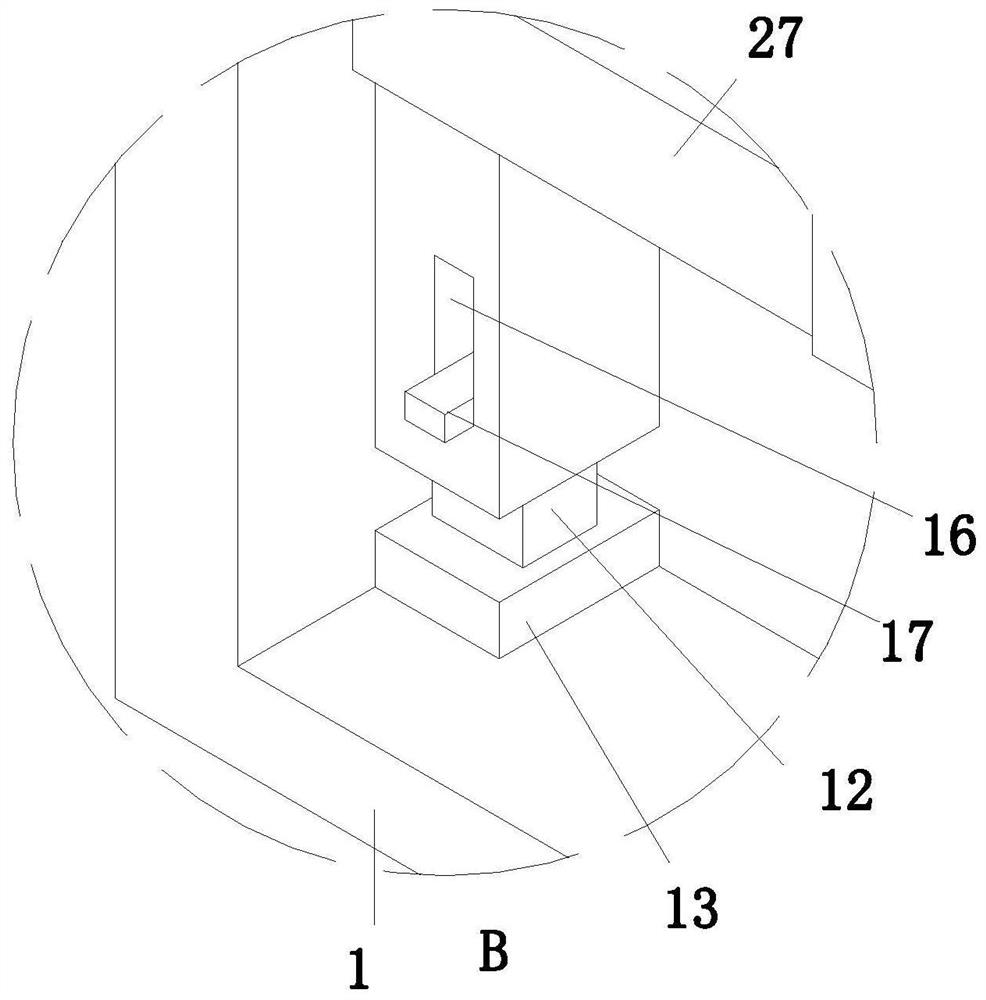

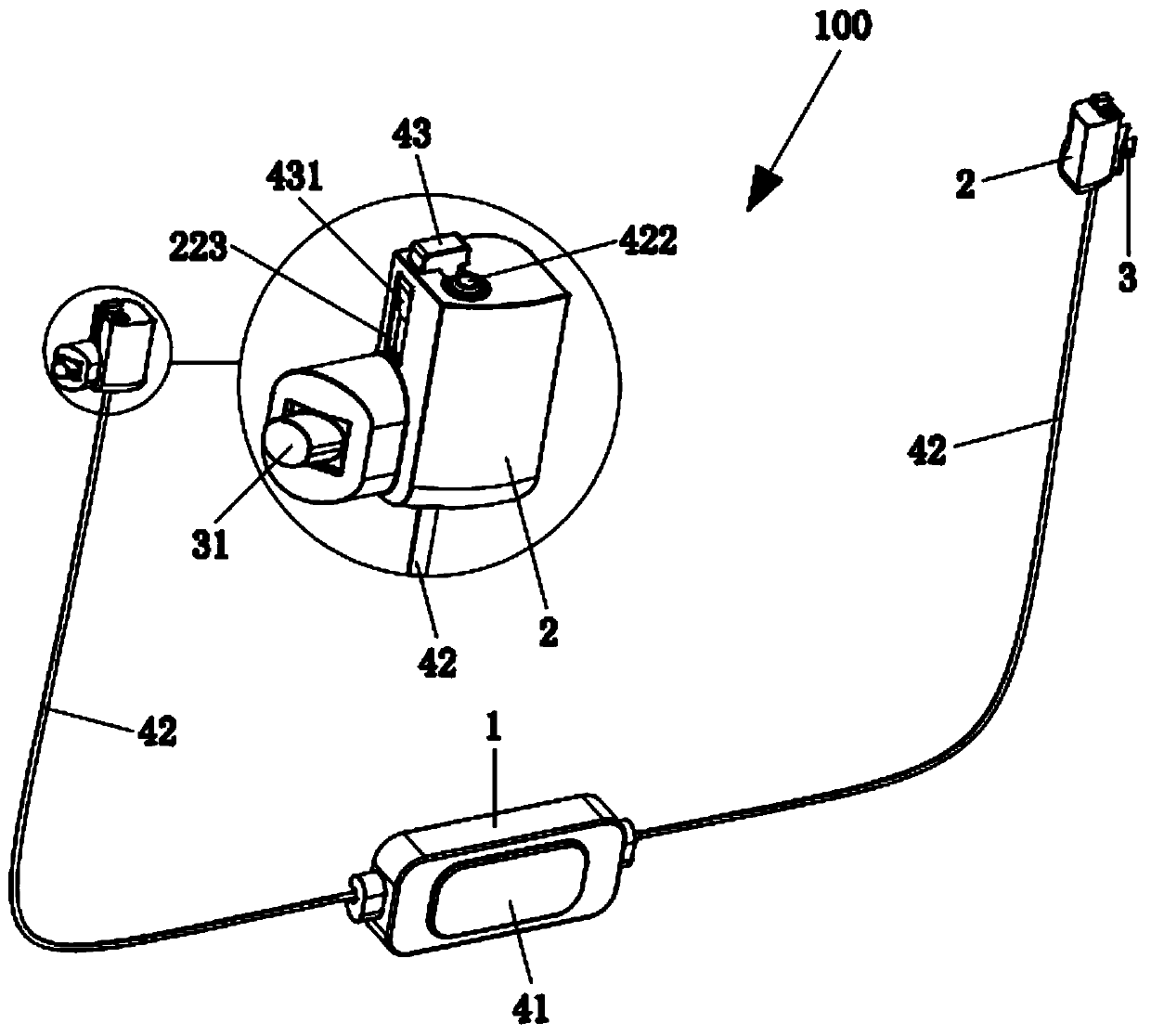

Power component locking installation device of electrical cabinet

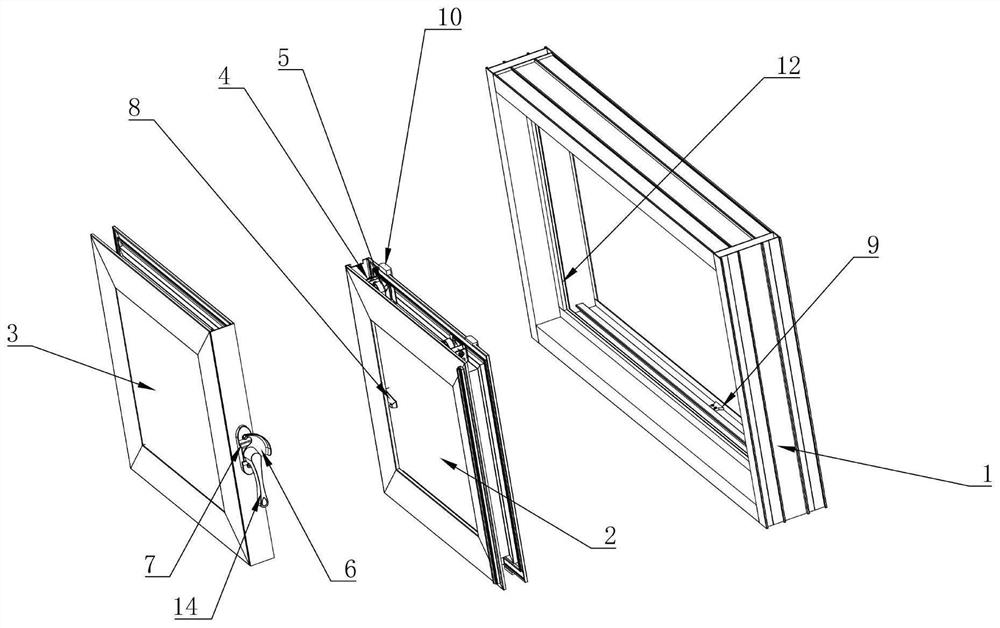

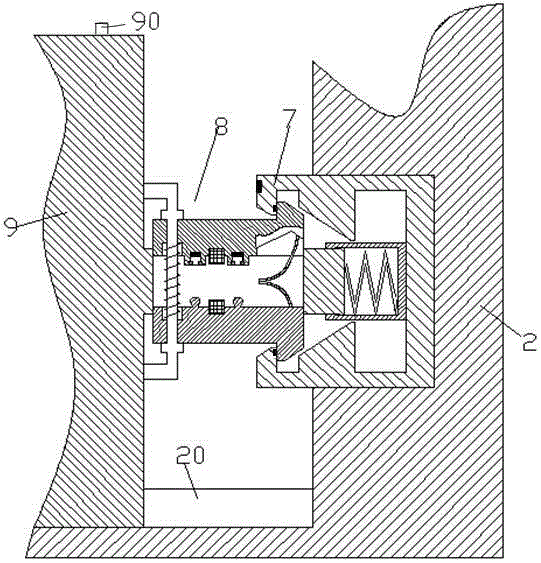

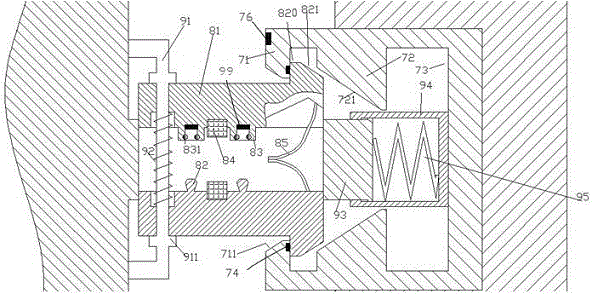

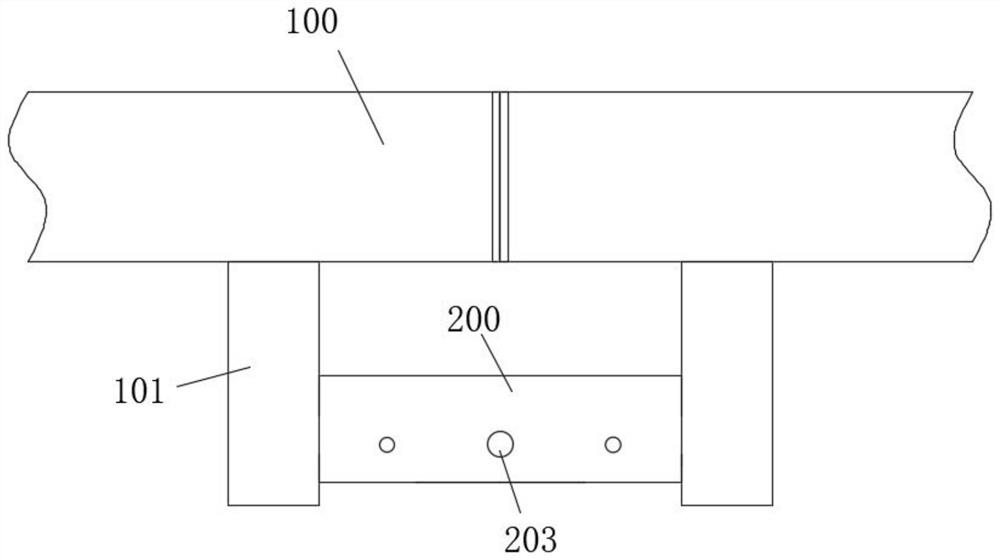

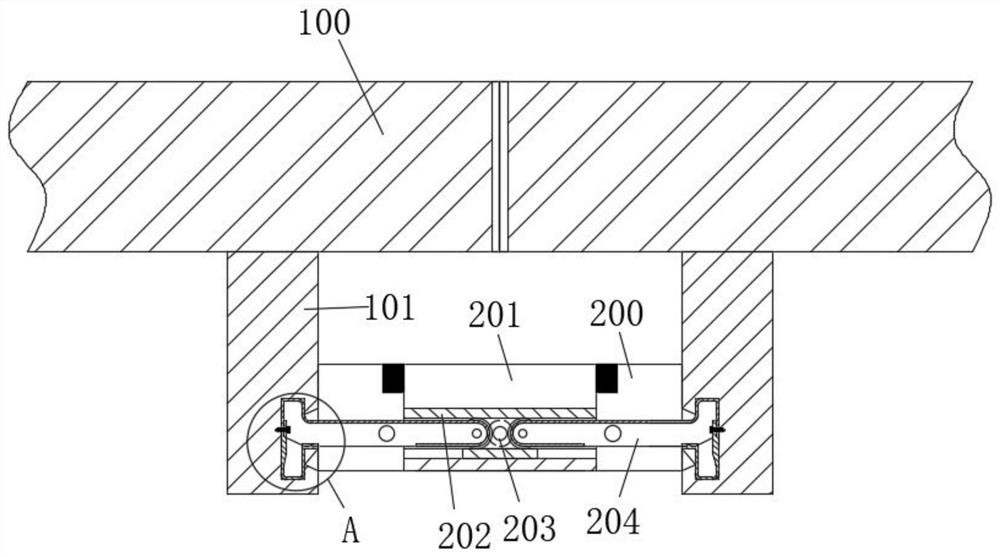

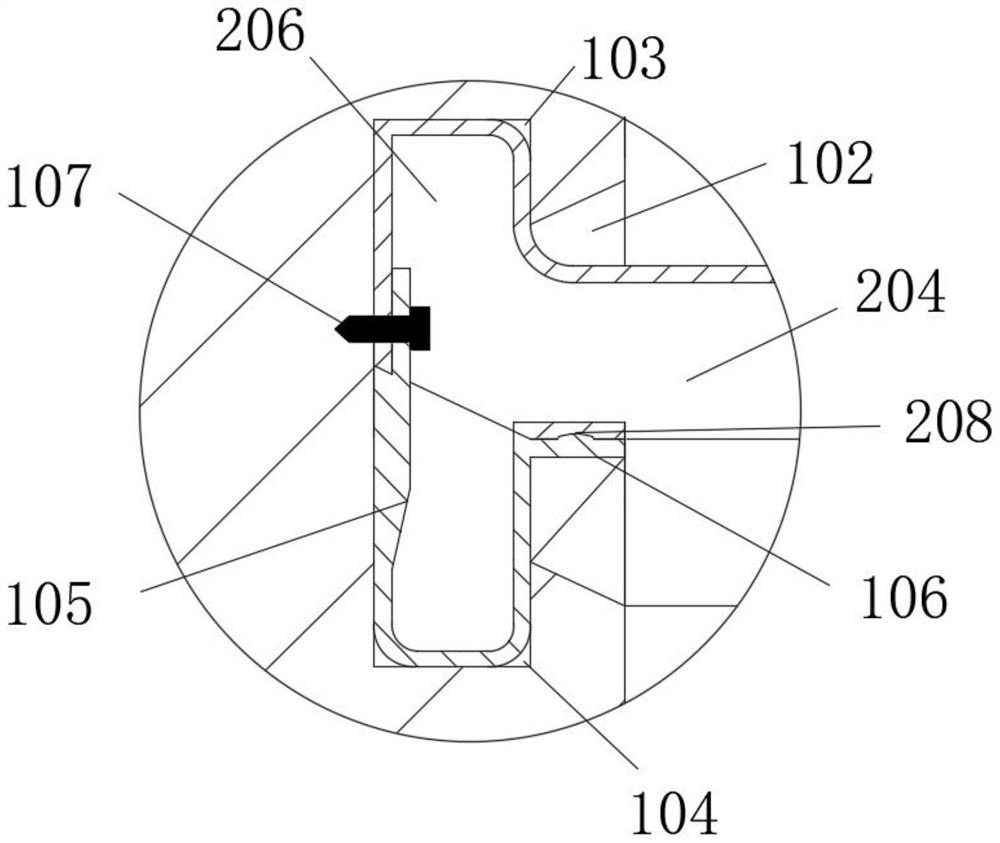

InactiveCN105704968AEven by forceRealize the locking effectClamping/extracting meansComponent plug-in assemblagesEngineeringPower component

A power component locking installation device for an electrical cabinet, comprising an electrical cabinet body (2) with a horizontal rail (20) and a power component (9) capable of sliding on the horizontal rail (20), the electrical cabinet A locking and unlocking insert (7) is fixedly arranged on the vertical rear wall of the body (2), wherein, the power element (9) is fixedly arranged with a device for protruding into the inner cavity of the locking and unlocking insert (7) The protruding part (93) is provided with a sliding cavity for slidingly installing two symmetrically arranged locking sliding wedges (81).

Owner:徐萍

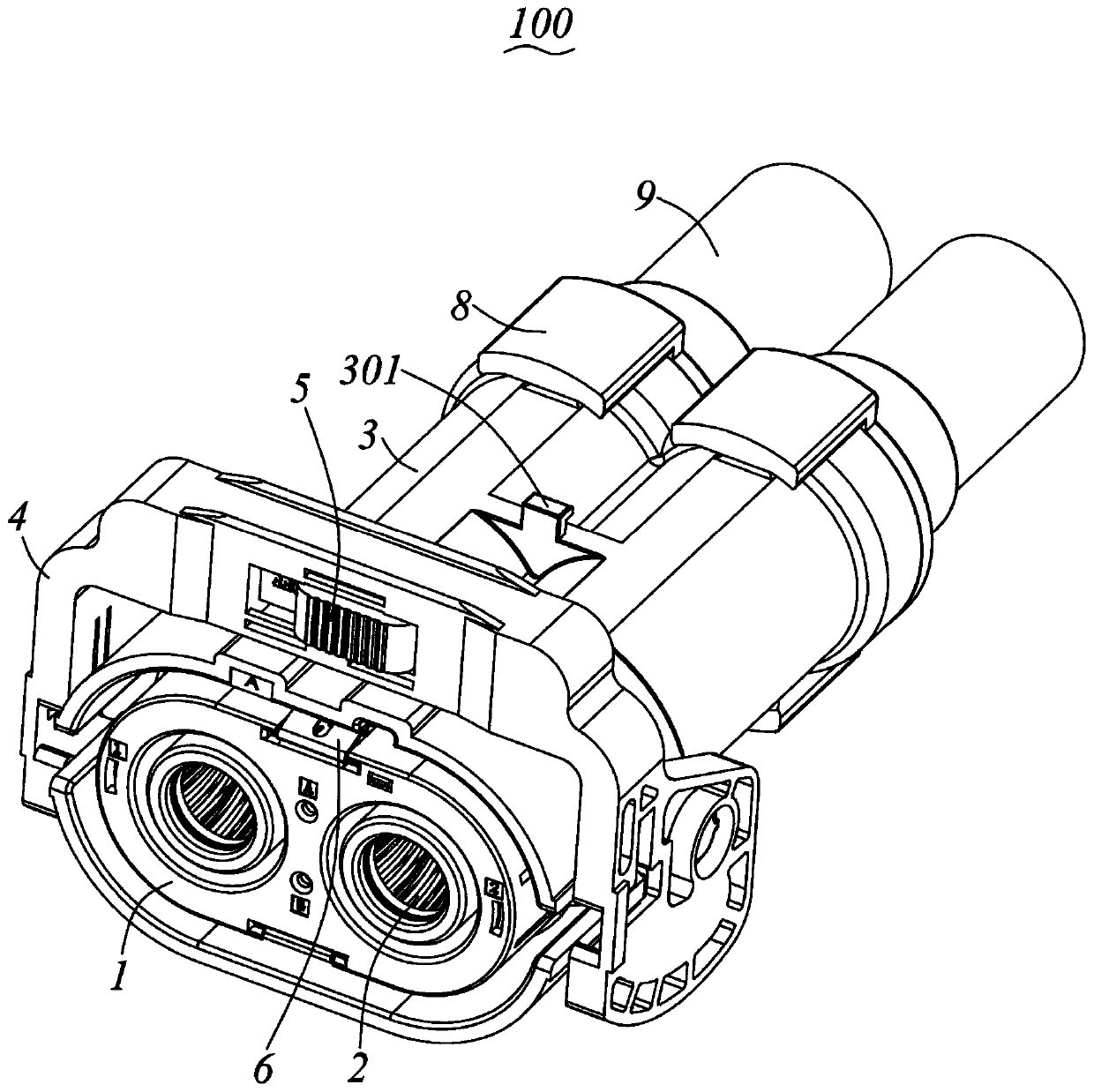

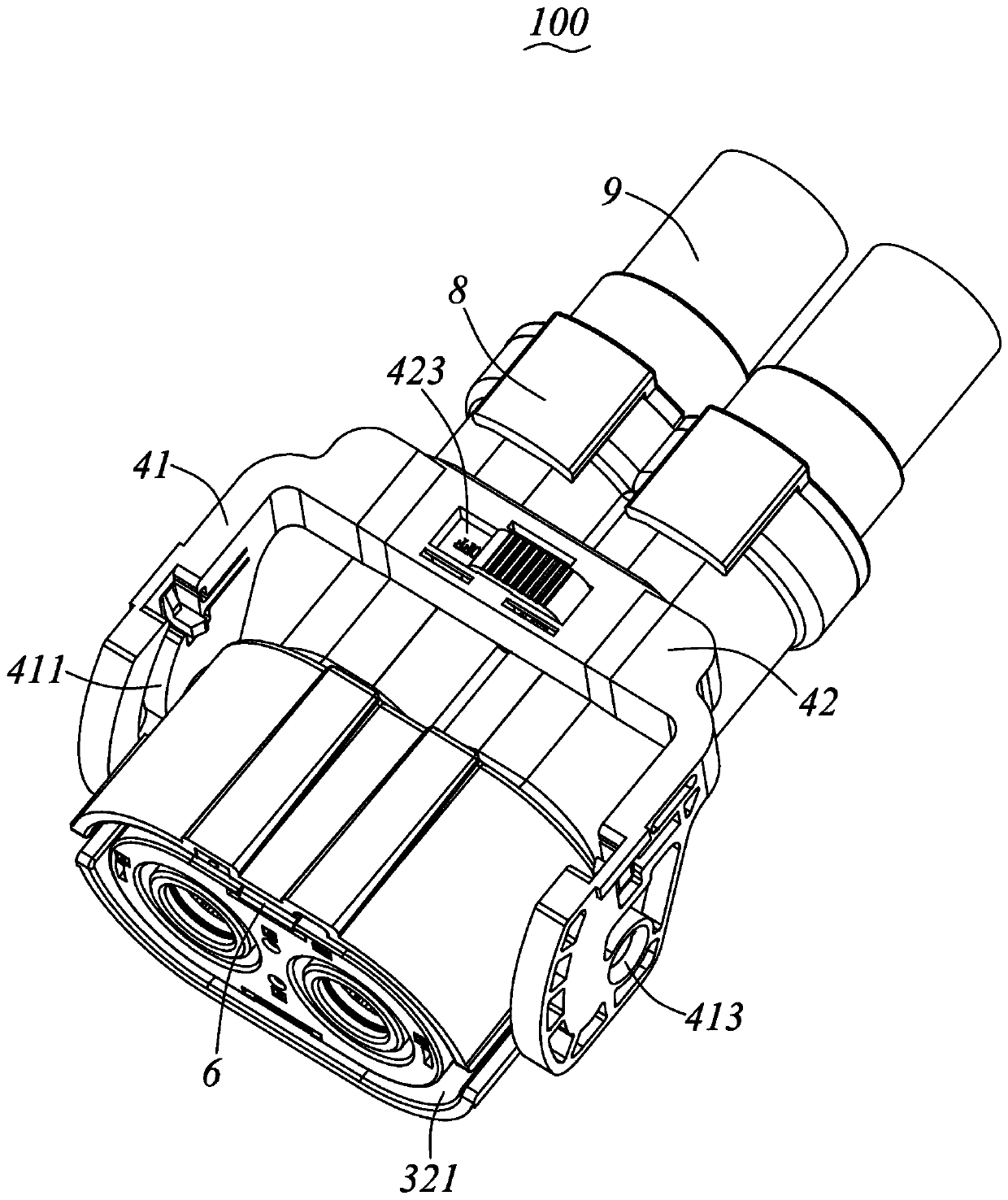

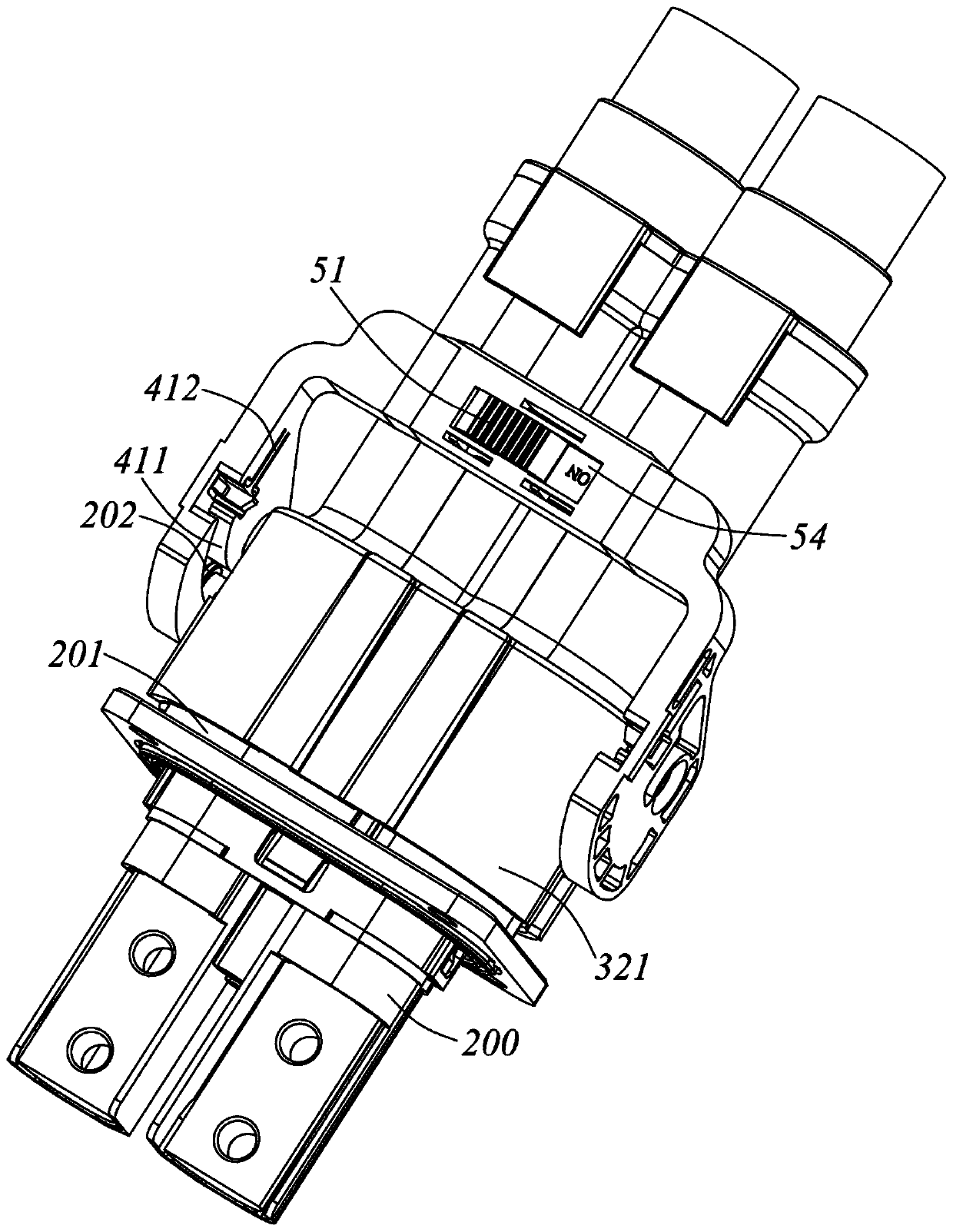

Electric connector and electric connector assembly

PendingCN110752485AImprove locking forceRealize the locking effectCoupling device detailsStructural engineeringMechanical engineering

The invention provides an electric connector and an electric connector assembly. The electric connector comprises an insulating body, a conductive terminal fixedly held on the insulating body, a shellsleeved outside the insulating body, and a rotating member rotatably arranged outside the shell, wherein the rotating member comprises a pair of rotating arms which are oppositely arranged and are rotationally connected with the shell and a connecting arm for connecting the pair of rotating arms. The electric connector is further provided with a padlock piece installed on the connecting arm, wherein the padlock piece is movably arranged relative to the connecting arm so as to realize hanging, buckling and separation with the shell. When the rotating arm rotates from an initial non-butt-jointstate to an initial lock catch state under the action of an insertion force of a butt-joint connector, the padlock piece translates from a first position to a second position, and then the padlock piece is buckled with a hanging lug arranged on the shell in a hanging mode so as to achieve secondary locking. The electric connector and the electric connector assembly have good locking force so as toensure the stability of electric connection.

Owner:东台正耀精密技术有限公司

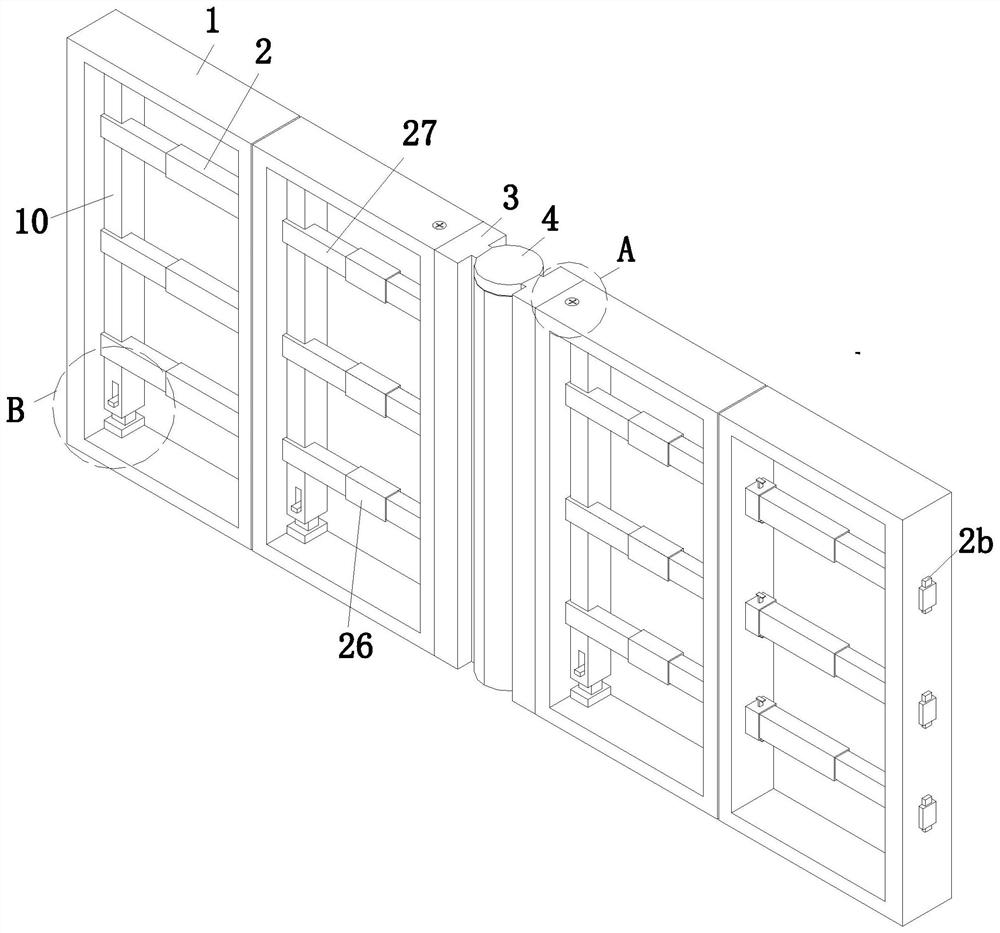

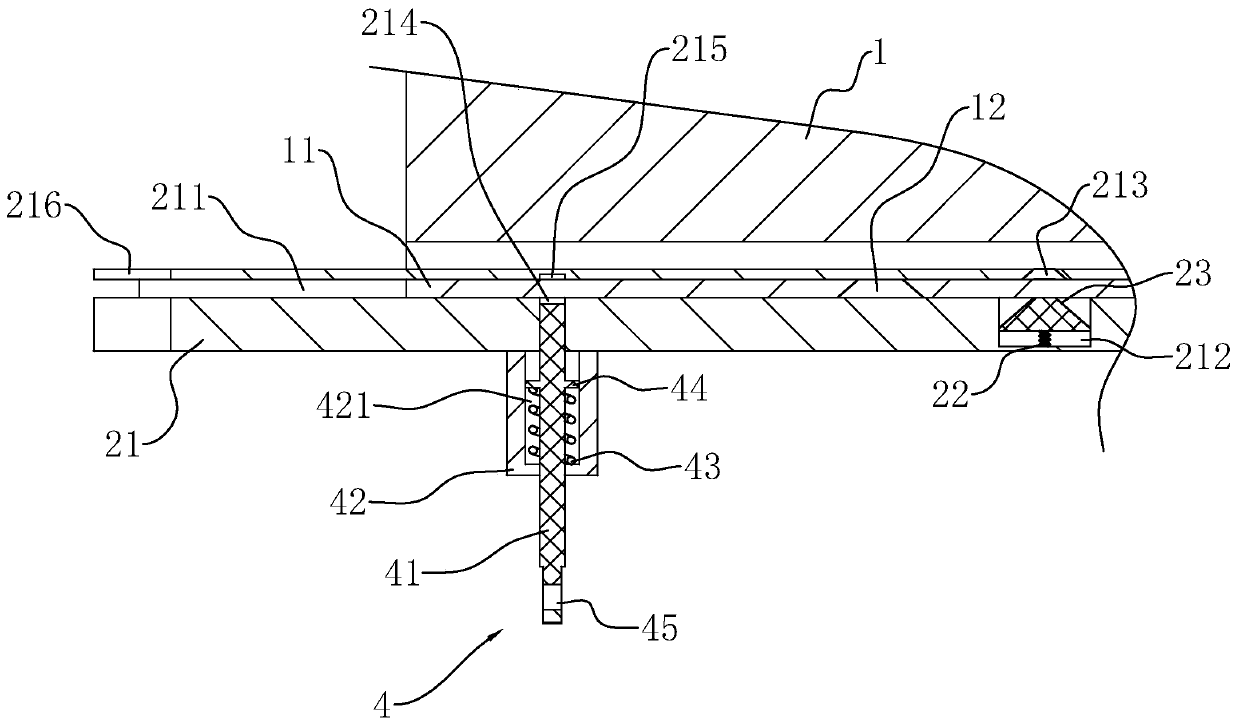

Module assembly type building aluminum alloy formwork

InactiveCN113216604AAvoid the phenomenon that the scope of use is reducedAvoid inconvenienceAuxillary members of forms/shuttering/falseworksForming/stuttering elementsEngineeringStructural engineering

The invention relates to a module assembly type building aluminum alloy formwork. The module assembly type building aluminum alloy formwork comprises unit modules, a connecting mechanism, an angle adjusting mechanism and a locking mechanism. According to the module assembly type building aluminum alloy formwork, the two unit modules can be spliced and installed by virtue of the connecting mechanism and can also be disassembled, the phenomena of inconvenience in transportation and inconvenience in disassembly and assembly due to fixed welding of a traditional aluminum alloy formwork are avoided, the working efficiency is greatly improved, additionally, the two spliced unit modules can be connected by virtue of the angle adjusting mechanism, and the angle can be adjusted, so that the multi-angle transformation effect is achieved between the unit modules, the use range of the unit modules is widened, and the phenomenon that the use range of the unit modules is reduced after the unit modules are fixedly welded is avoided.

Owner:海红社

Power component locking device for electrical cabinet

InactiveCN105704977AEven by forceRealize the locking effectPrinted circuit board receptaclesMounting boards securingPower componentElectric power

A power component locking device for an electrical cabinet, comprising an electrical cabinet body (2) with a horizontal rail (20) and a power component (9) capable of sliding on the horizontal rail (20), the electrical cabinet A locking and unlocking insert (7) is fixedly arranged on the vertical rear wall of the cabinet body (2), wherein, the power element (9) is fixedly arranged with a device for extending into the inner cavity of the locking and unlocking insert (7) The protruding part (93) in the protruding part (93) is provided with a sliding cavity for slidingly installing two symmetrically arranged locking sliding wedges (81).

Owner:叶葵

Novel type electric power component locking apparatus for electric cabinet

InactiveCN105916345AEven by forceRealize the locking effectClamping/extracting meansEngineeringMechanical engineering

The invention provides a novel type electric power component locking apparatus for electric cabinet. The component comprises an electric cabinet body (2) with a horizontal track (20) and a sliding electric component (9) able to slide along the horizontal track (20). The upright back wall of the electric cabinet body (2) is fixedly provided with a locking and unlocking embedded piece (7). The sliding electric component (9) is fixedly provided with a protruding part (93) which extends into the inner cavity of the locking and unlocking embedded piece (7). The protruding part (93) is provided with a sliding cavity, allowing two symmetrically arranged locking and sliding wedges (81) to be flexibly mounted.

Owner:YIWU PIKEYA IMPORT & EXPORT CO LTD

Electric element locking device of electrical cabinet

InactiveCN105764294AEven by forceRealize the locking effectSubstation/switching arrangement detailsResilient/clamping meansEngineeringMechanical engineering

Owner:徐萍

Electric power element locking device with disassembly indication

InactiveCN105846231AEven by forceRealize the locking effectCoupling device detailsEngineeringMechanical engineering

The present invention provides an electric power element locking device with a disassembly indication. The electric power element locking device with disassembly indication comprises an electrical cabinet body (2) with a horizontal track (20) and an electric power element (9) capable of sliding on the horizontal track (20); a locking unlock embedded part (7) is fixedly arranged at the vertical back wall of the electrical cabinet body (2), wherein a projecting part (93) stretching into the inner cavity of the locking unlock embedded part (7) is fixedly arranged on the electric power element (9), and a sliding cavity is arranged in the projecting part (93) and is configured to slidingly install two locking sliding wedges (81) symmetrically arranged.

Owner:HANGZHOU QIAOER ARTS & CRAFTS CO LTD

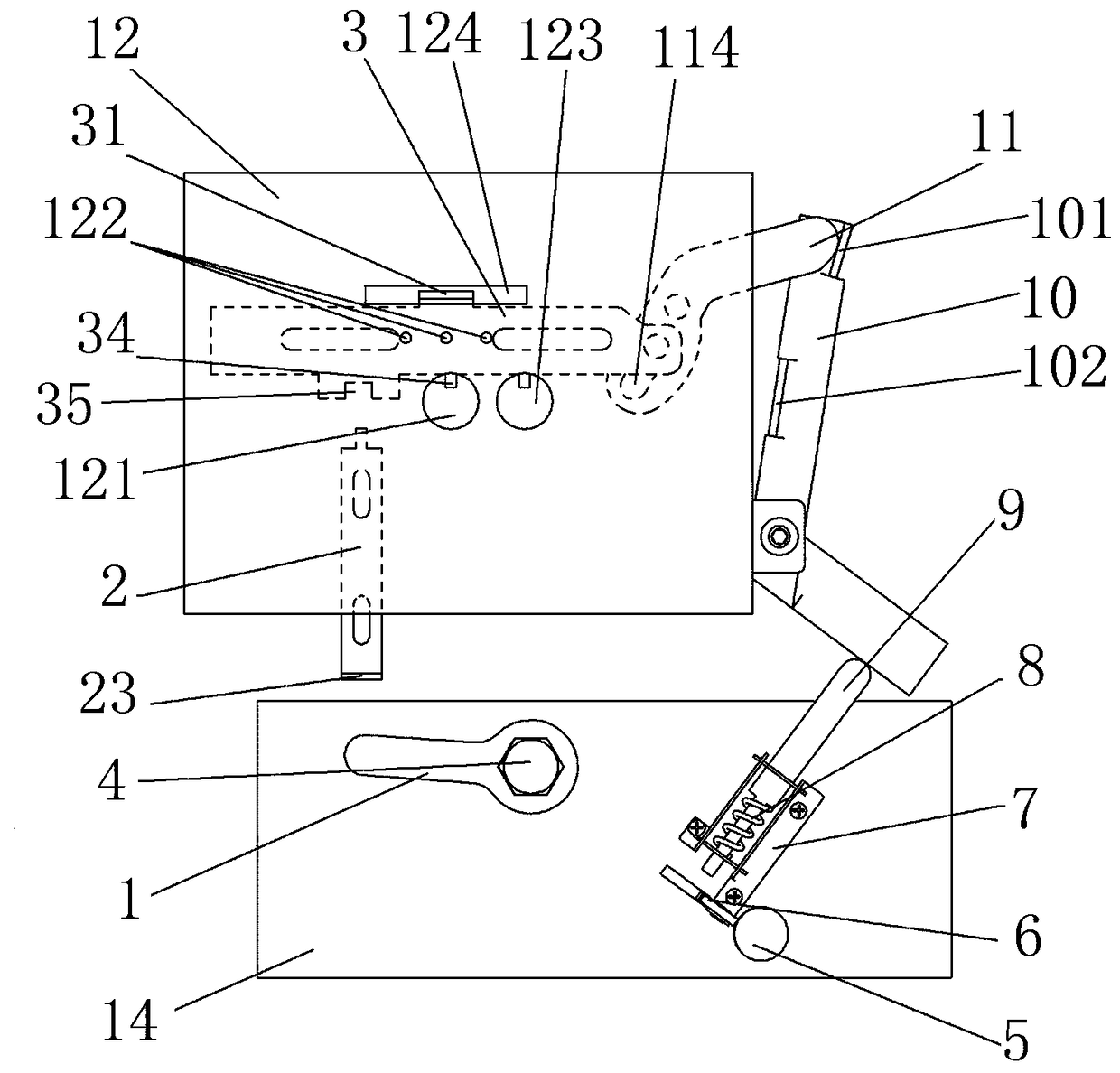

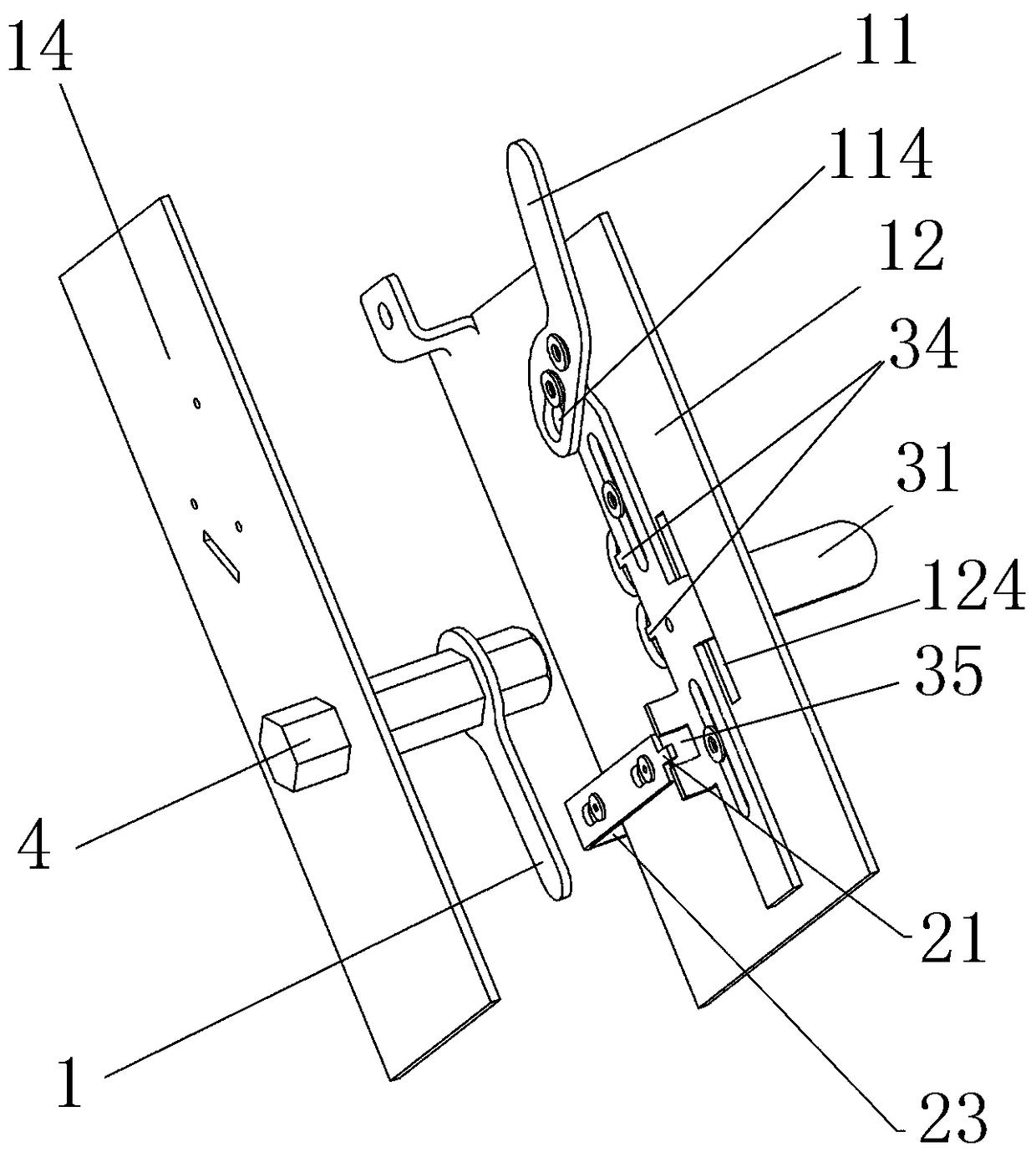

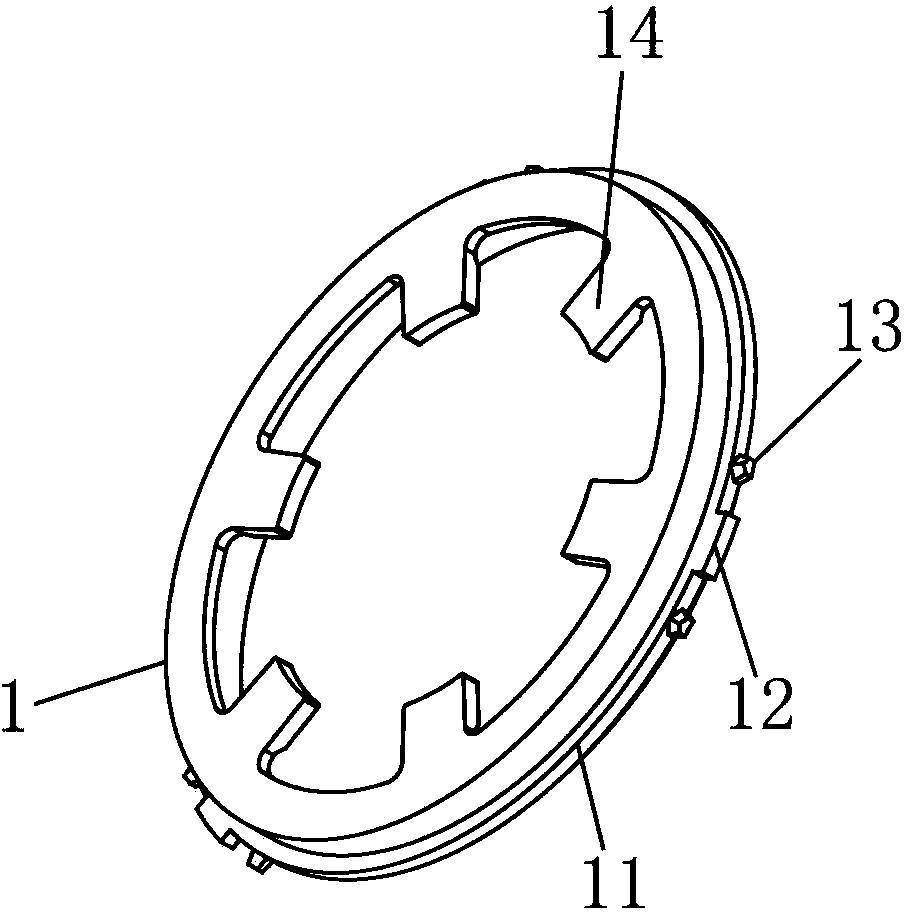

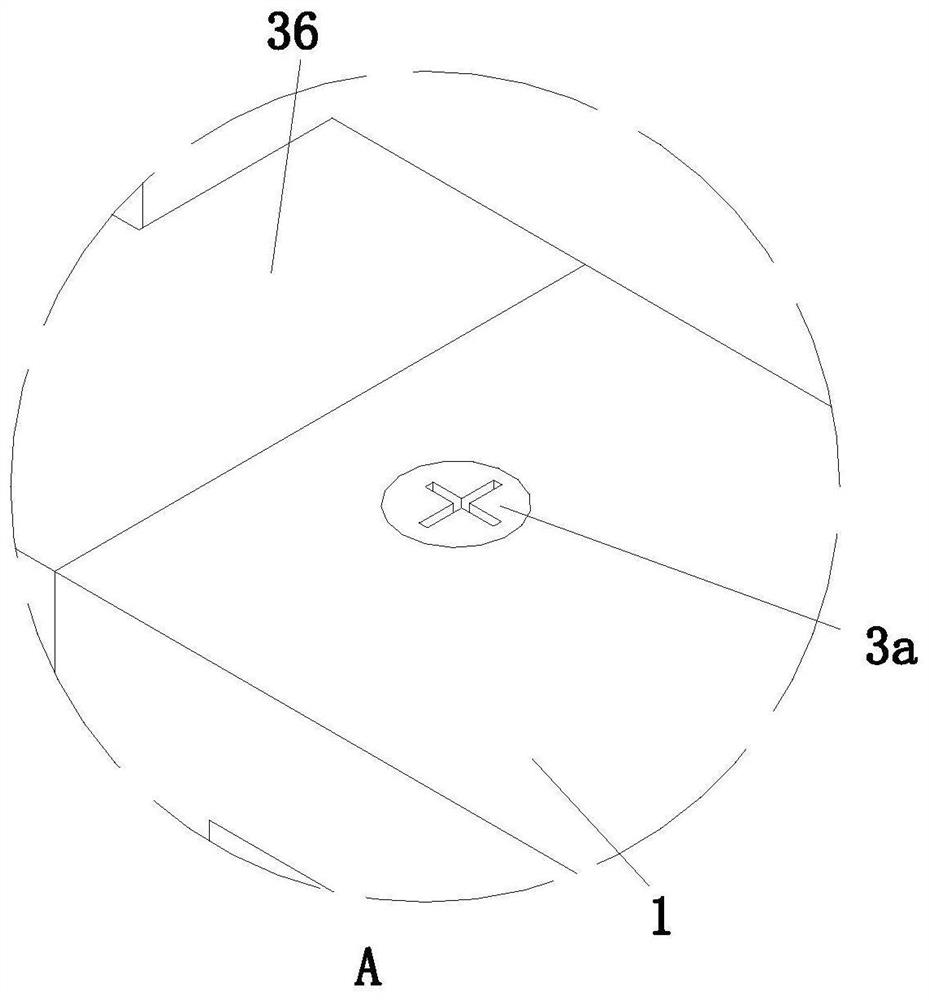

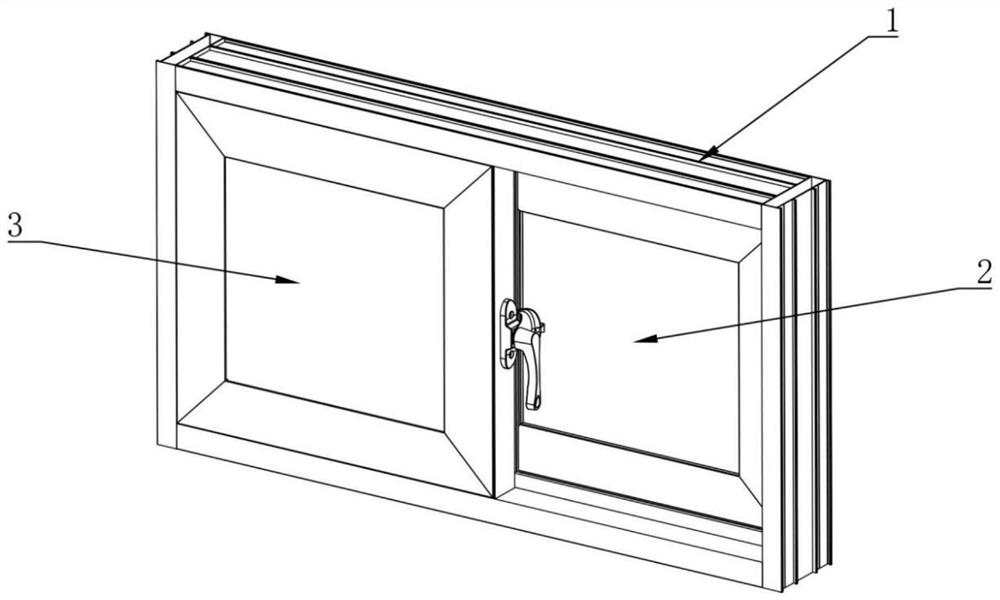

Simple translational seal window

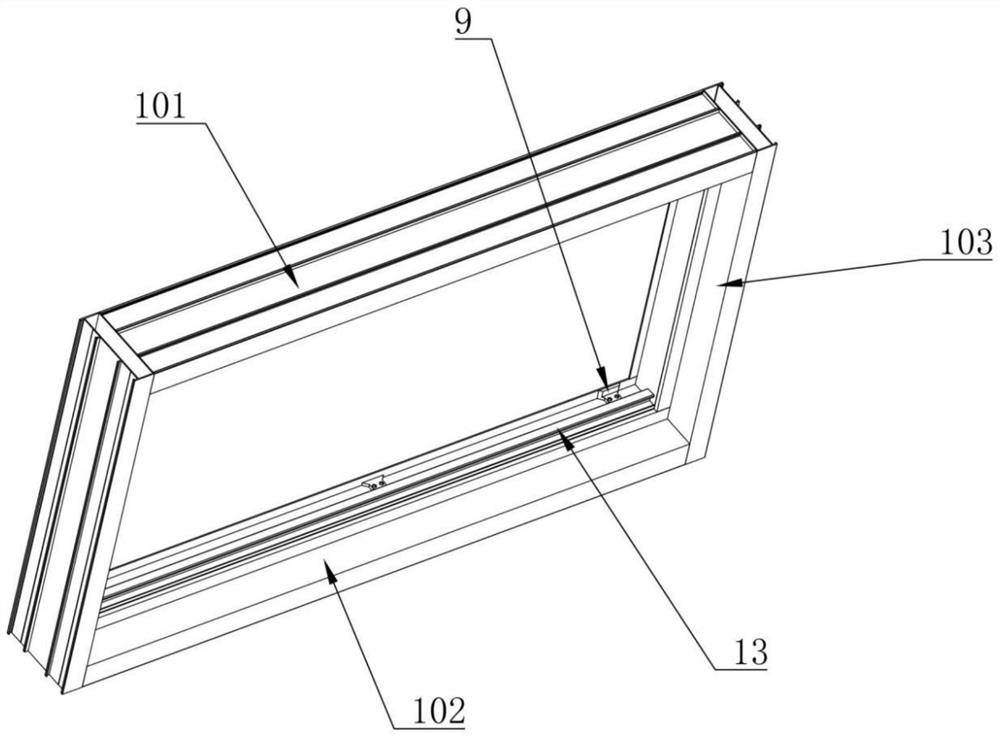

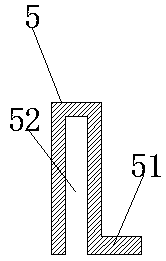

PendingCN111810020ASimple structureImprove sealingConstruction fastening devicesSealing arrangementsSash windowClassical mechanics

The invention provides a simple translational seal window. The simple translational seal window comprises an outer frame, a movable sash and a fixed sash; the fixed sash is fixedly arranged on the outer frame, and the movable sash is slidably arranged on a rail of the outer frame through a pulley assembly; the fixed sash and the movable sash are connected and locked through a crescent lock assembly; the pulley assembly comprises a pulley fixing seat and a pulley set; the pulley set is arranged on the movable sash through the pulley fixing seat; the crescent lock assembly comprises a handle, acrescent lock hook, a crescent lock disc and a base, the crescent lock disc and the handle are rotationally arranged on the base, and the crescent lock disc is matched with the crescent lock hook on the movable sash; and a sliding block assembly is further arranged between the outer frame and the movable sash and comprises a fixed block and a sliding block, the fixed block is fixedly arranged on the outer frame, and the sliding block is fixedly arranged on one side of the movable sash. The simple translational seal window is simple in overall structure, the opening, locking and sealing effectof sashes can be achieved through the crescent lock assembly, the sliding block assembly and the pulley assembly, and the sealing effect is better.

Owner:宁波锐驰科技有限公司

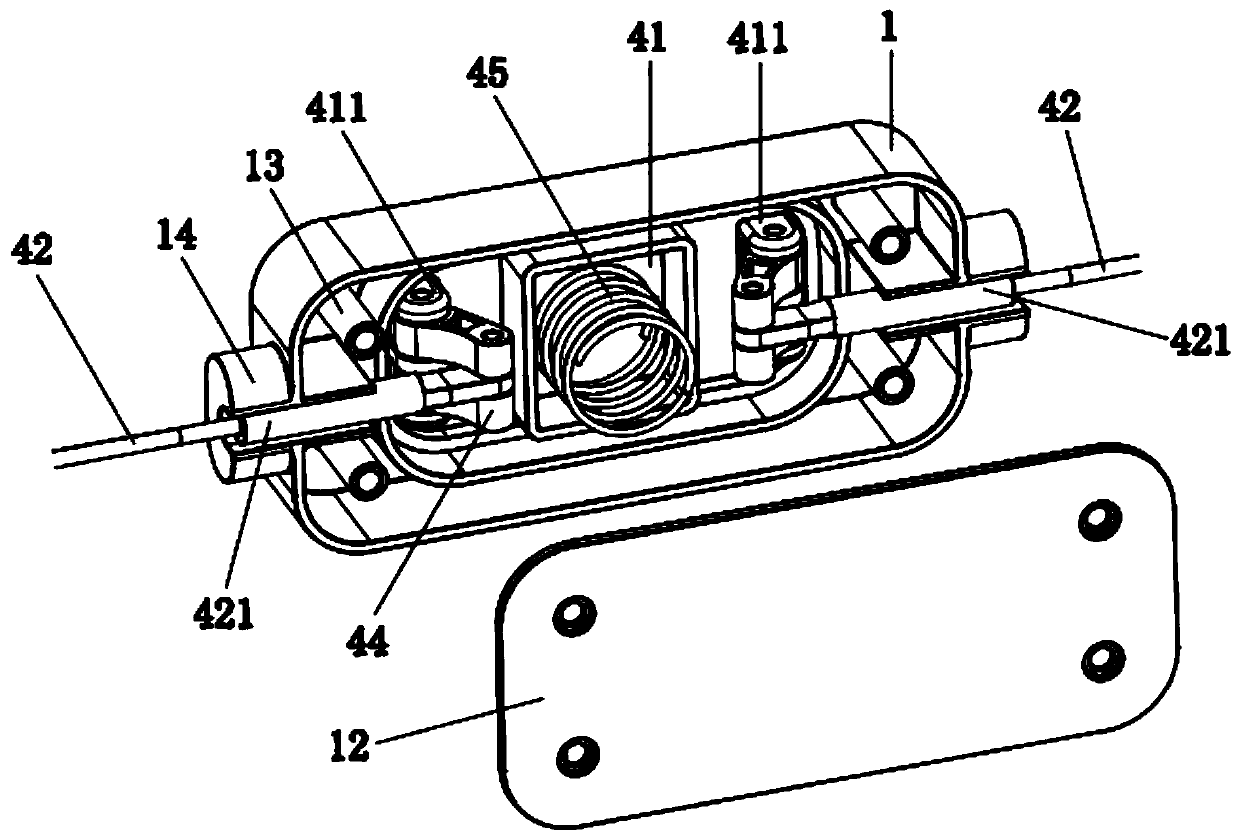

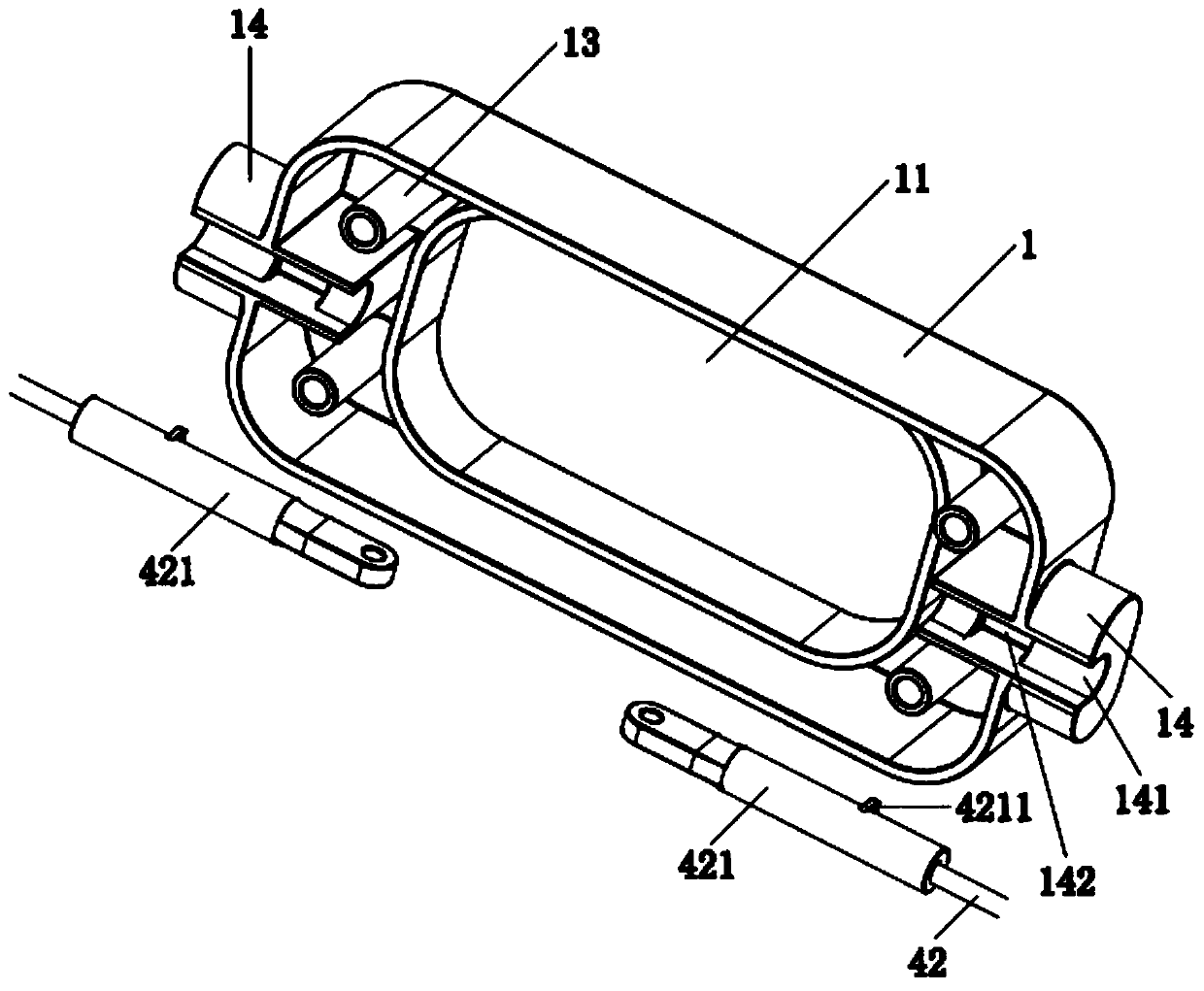

Power component locking and mounting device

InactiveCN105720486AEven by forceRealize the locking effectSubstation/switching arrangement detailsEngineeringPower component

A locking installation device for power components, comprising an electrical cabinet body (2) having a horizontal rail (20) and a power component (9) capable of sliding on the horizontal rail (20), the electrical cabinet A locking and unlocking insert (7) is fixedly arranged on the vertical rear wall of the body (2), wherein the power element (9) is fixedly arranged to protrude into the inner cavity of the locking and unlocking insert (7) The protruding part (93) of the protruding part (93) is provided with a sliding cavity for slidingly installing two symmetrically arranged locking sliding wedges (81).

Owner:HANGZHOU QIAOER ARTS & CRAFTS CO LTD

Locking device and luggage case with same

PendingCN111184330AEasy to operateLabor-saving operationLuggageOther accessoriesTrunk compartmentStructural engineering

The invention discloses a locking device. The locking device comprises a shell, a locking seat, a locking mechanism and a linkage mechanism, an accommodating cavity is formed on the locking seat, andthe locking mechanism comprises a lock pin and a first spring. The lock pin is arranged in the accommodating cavity, the first spring abuts against the lock pin, and the linkage mechanism comprises abutton, a pull rope and a thrust piece. The button is arranged on the shell, the lower end of the pull rope is connected with the button, the upper end of the pull rope is connected with the thrust piece, and one end of the lock pin retracts into / stretches out of the accommodating cavity through the thrust piece. The present invention further discloses a luggage case which comprises a lower case body, an upper case body and the locking device. A lower lock hole is formed on the lower case body, at least two upper lock holes are formed on the upper case body, and the lock pin extends into the lower lock hole and is inserted into one upper lock hole so as to connect the lower case body and the upper case body together. The locking device is very convenient and labor-saving to operate, and the luggage case disclosed by the invention not only can meet different requirements for use and placement, but also is very convenient to adjust the size.

Owner:张效益 +1

Simple-unlocking electric power element locking equipment

InactiveCN105790090AAchieve lockingReduce vibration forceSubstation/switching arrangement detailsEngineeringMechanical engineering

Simple-unlocking electric power element locking equipment comprises the components of an electrical cabinet body (2) with a horizontal track (20), and an electric power element (9) which can slide on the horizontal track (20). The vertical back wall of the electrical cabinet body (2) is provided with a locking / unlocking insert (7) which is arranged fixedly, wherein a projection (93) which is used for extending into the inner chamber of the locking / unlocking insert (7) is fixedly arranged on the electric power element (9). The projection (93) is internally provided with a sliding chamber for slidably mounting two locking / unlocking wedge blocks (81) which are symmetrically arranged.

Owner:HANGZHOU QIAOER ARTS & CRAFTS CO LTD

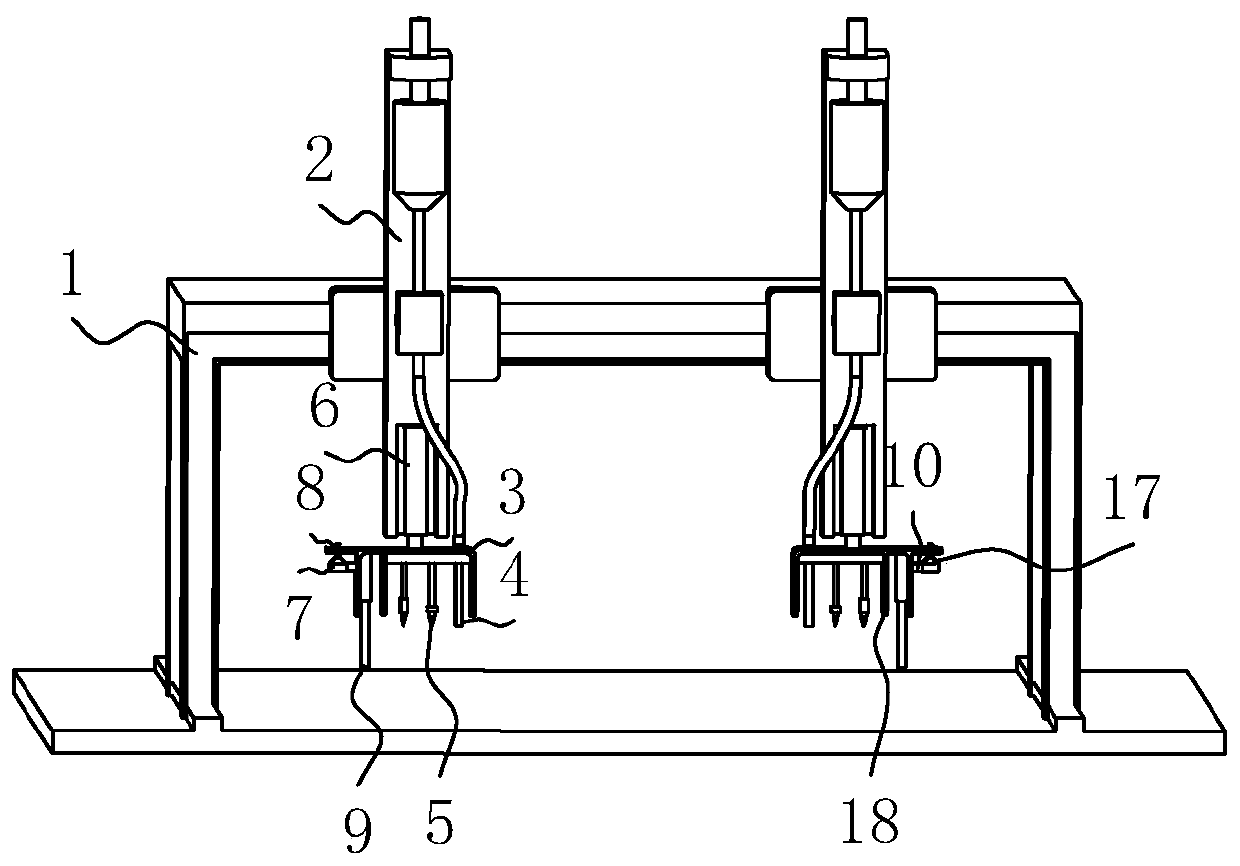

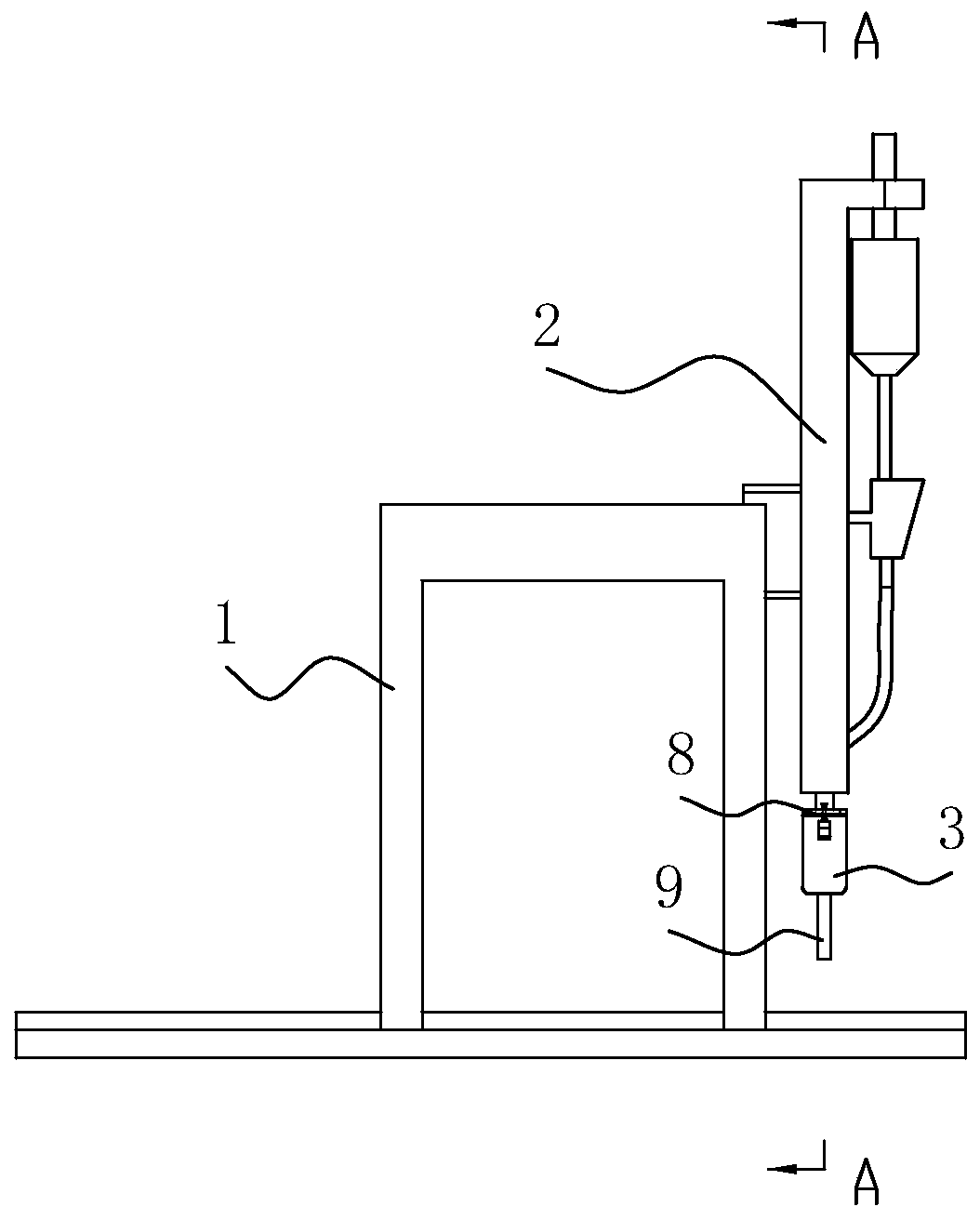

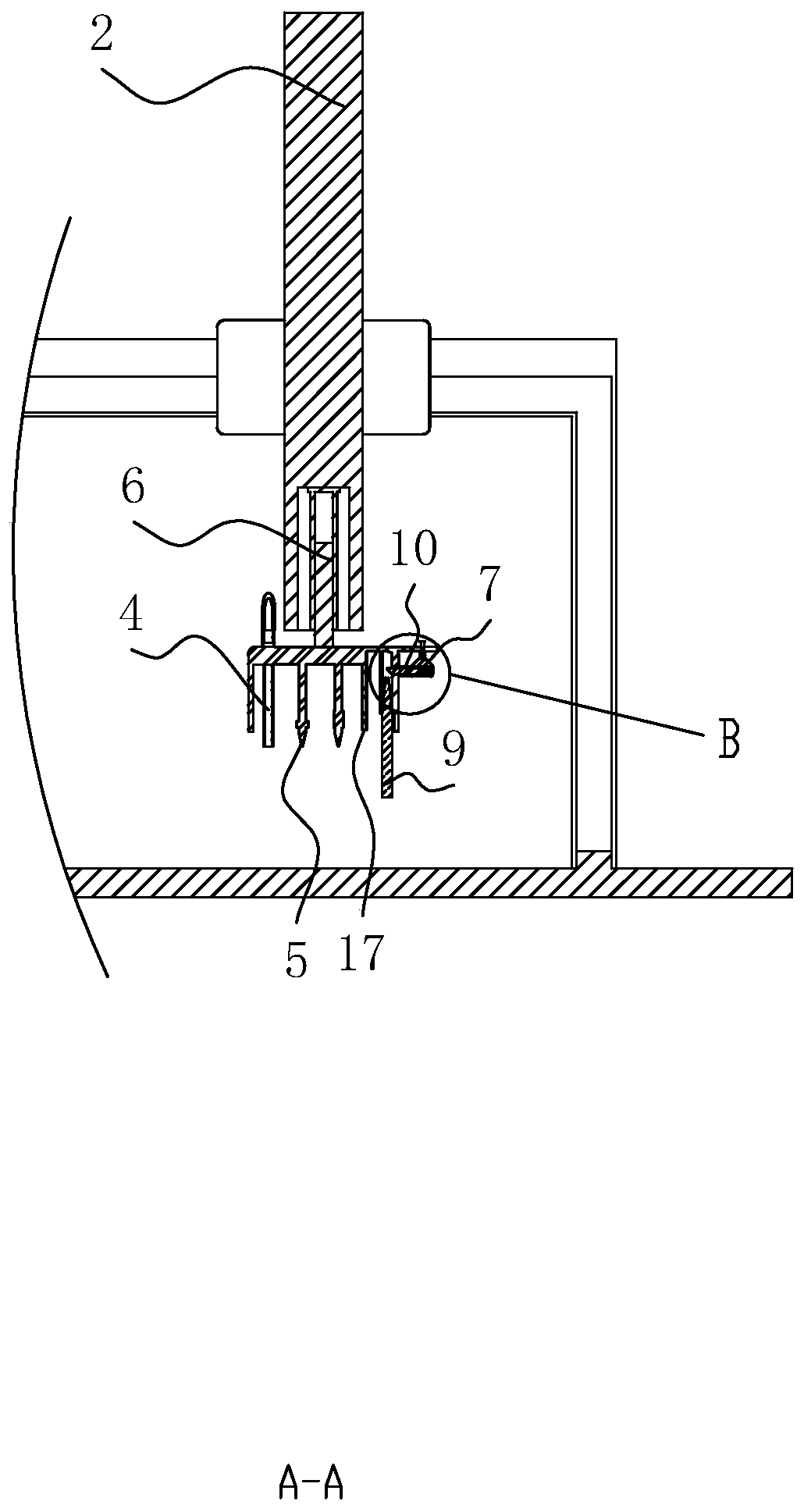

Double-wire automatic submerged arc welding machine

ActiveCN110899923ARealize the locking effectAchieve protectionSupport devices with shieldingWelding accessoriesStructural engineeringMechanical engineering

The invention discloses a double-wire automatic submerged arc welding machine, which comprises a machine body and a support, wherein an operation table is arranged on the support in a sliding mode, awelding flux pipe and a welding gun are fixedly arranged on the operation table, and an air cylinder for driving the operation table to move is fixedly arranged on the support; the operation table isprovided with an identification block used for identifying the position of the welding gun in a sliding mode, and a vertically-arranged first spring is fixedly connected between the operation table and the identification block; and a detection rod is arranged on the operation table in a sliding mode in the vertical direction, the detection rod abuts against the welding position of the workpiece, and a transmission assembly for achieving upward ejection of the identification block is arranged between the detection rod and the operation table. By means of the technical scheme, the effect of identifying the position of the welding gun is conveniently achieved, the welding gun is ensured to be controlled to move to the working position, the labor intensity of workers is reduced, and the welding working quality is improved.

Owner:武汉求精钢结构有限公司

Simple spliced safe fence for breeding livestock

The invention discloses a simple spliced safe fence for breeding livestock. The safe fence comprises a plurality of vertical pillars and fences connected between every two vertical pillars, wherein aU-shaped groove is formed in the top end of each vertical pillar; opening-closing parts which are correspondingly inserted with the U-shaped grooves and are provided with openings in the bottom ends are processed on two sides of the top end of each fence; two sides of the bottom end of each vertical pillar are in threaded connection with L-shaped groove plates; rotary positioners are arranged on the L-shaped groove plates; the bottom ends of the fences are welded with positioning blocks which are vertically clamped with the rotary positioners. According to the fence, the spliced structure is adopted; the spliced structure is simple and relatively convenient to mount and dismount; the mounted fence is high in stability.

Owner:泰州市润扬电气有限公司

High-stability power component locking device

InactiveCN105704976AAchieve lockingControl elastic forcePrinted circuit board receptaclesMounting boards securingEngineeringPower component

A power component locking device with high stability, comprising an electrical cabinet body (2) with a horizontal track (20) and a power component (9) capable of sliding on the horizontal track (20), the electrical cabinet A locking and unlocking insert (7) is fixedly arranged on the vertical rear wall of the body (2), wherein, the power element (9) is fixedly arranged with a device for protruding into the inner cavity of the locking and unlocking insert (7) The protruding part (93) is provided with a sliding cavity for slidingly installing two symmetrically arranged locking sliding wedges (81).

Owner:叶葵

Power component locking device mounted in power cabinet

InactiveCN105722359AEven by forceRealize the locking effectClamping/extracting meansComponent plug-in assemblagesPower component

The invention discloses a power component locking device mounted in a power cabinet. The device comprises an electrical cabinet body (2) with a horizontal track (20) and a power component (9) capable of sliding on the horizontal track (20); a locking and unlocking embedding element (7) is fixedly arranged on the vertical rear wall of the electrical cabinet body (2); wherein a lug boss (93) which is used for stretching into the cavity of the locking and unlocking embedding element (7) is fixedly arranged on the power component (9); a sliding cavity is arranged in the lug boss (93); and two locking sliding wedge blocks (81) are mounted in the sliding cavity symmetrically in a sliding mode.

Owner:BIWANGJIA MECHANICAL TECH SHENZHEN CO LTD

Installing and locking device for electric element

InactiveCN105934132AEven by forceRealize the locking effectClamping/extracting meansComponent plug-in assemblagesEngineeringMechanical engineering

Owner:XIAMEN MAIFENGWEI MACHINERY CO LTD

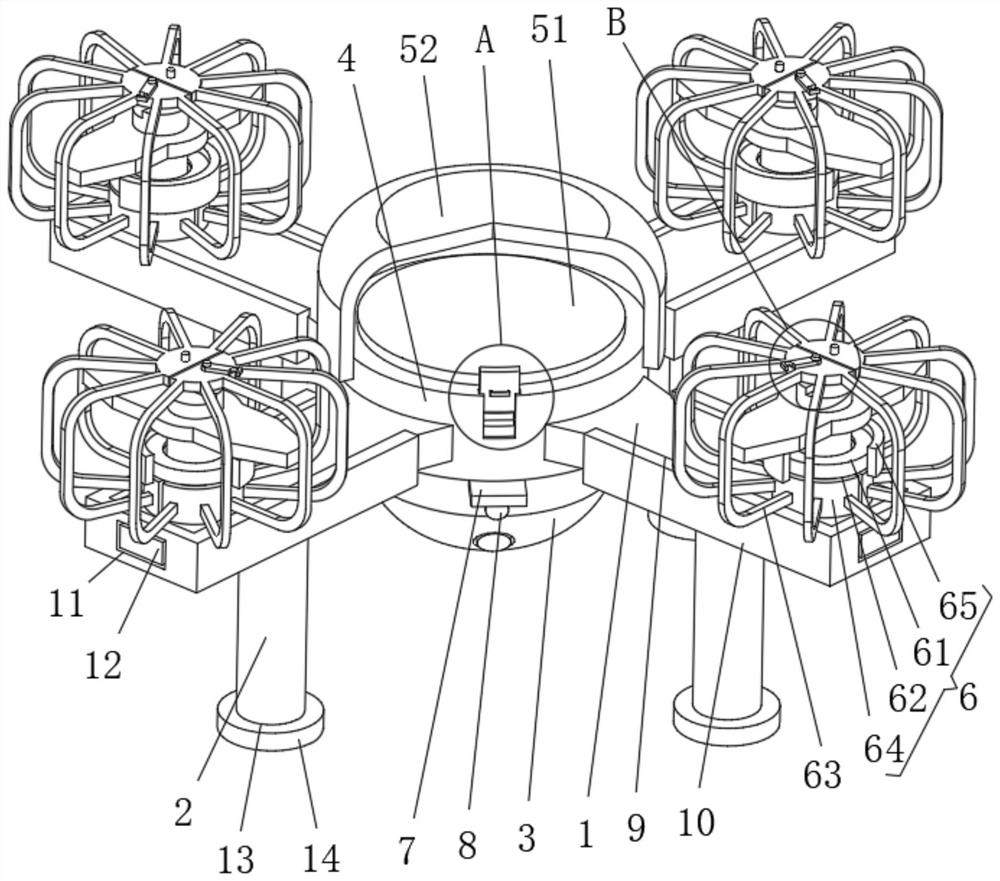

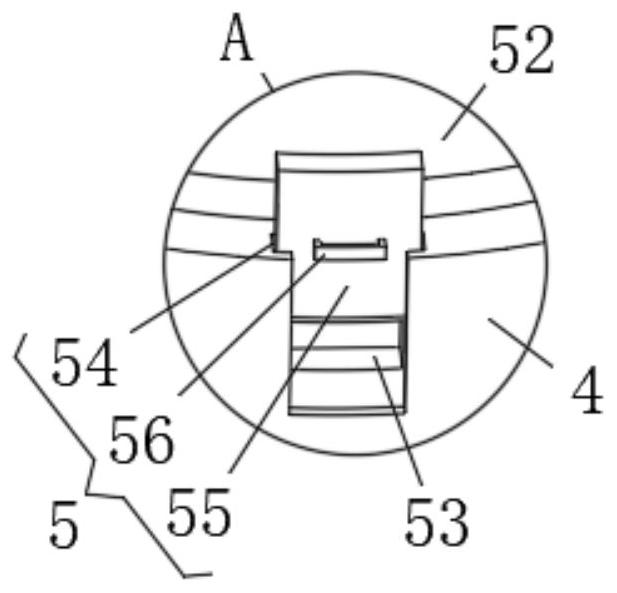

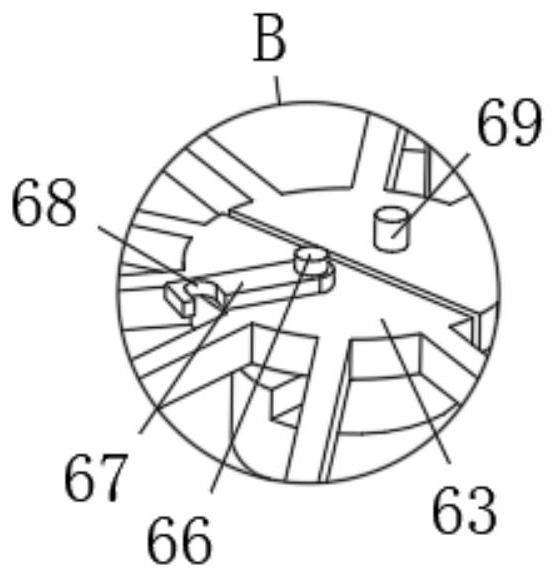

Unmanned aerial vehicle electric power inspection device

PendingCN113788141AAvoid collision situationsRealize the function of card connectionBatteries circuit arrangementsCharging stationsCircular discUncrewed vehicle

The invention discloses an unmanned aerial vehicle electric power inspection device which comprises an unmanned aerial vehicle body and a protection unit. The outer ends of the upper sides of four supporting rods of the unmanned aerial vehicle body are each provided with a paddle through a rotating shaft, four supporting legs are arranged on the lower side of the unmanned aerial vehicle body and located under the paddles, and a rotating camera is arranged in the middle of the lower side of the unmanned aerial vehicle body. A disc is arranged in the middle of the upper side of the unmanned aerial vehicle body, and a power unit is arranged on the disc. The protection unit comprises cylinders, circular ring grooves, eight semicircular frame protection shells, arc-shaped clamping blocks and locking assemblies, the four cylinders are arranged on the upper side of the unmanned aerial vehicle body and located on the outer sides of the corresponding rotating shafts correspondingly, the circular ring grooves are formed in the lower ends of the outer sides of the cylinders, wherein the two semicircular frame protection shells are clamped in a matched mode, under the action of threaded connection between the inner side of a circular ring and the outer side of an arc-shaped clamping block clamped in the matched mode, the effect of locking the lower ends of the two semicircular frame protection shells is achieved, and under the action of matched clamping between a connecting rod and a second pin shaft corresponding to a U-shaped groove, the locking effect on the upper ends of the two semicircular frame protection shells is achieved, so that damage to the unmanned aerial vehicle body caused by sudden collision of external flyers is prevented.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Metal roof mounting structure based on BIM technical design and construction method

ActiveCN113175098AStable and efficient connectionFirmly connectedRoof covering using slabs/sheetsStructural engineeringMechanical engineering

The invention discloses a metal roof mounting structure based on BIM technical design and a construction method, and belongs to the field of building roofs. The metal roof mounting structure comprises a plurality of sets of roof single bodies and mounting frames connecting every two adjacent roof single bodies, fixing pieces are arranged on the opposite sides of every two adjacent roof single bodies, a mounting groove is formed in the side wall of each fixing piece in the length direction, and connecting angle claws are rotationally mounted on the two sides of the interior of each mounting frame; one end of each connecting angle claw is slidably arranged on a corresponding push block, and the other end of each connecting angle claw is matched with a corresponding mounting groove after rotating by a certain angle; a guide groove is formed in the inner side wall of each mounting frame, each push block is slidably arranged in the corresponding guide groove, and the two ends of each push block are rotatably mounted on the corresponding connecting angle claws correspondingly; and locking pieces for fixing the push blocks are arranged on the mounting frames. The whole structure and operation are convenient to construct, the effect of reliable connection is achieved, and the design requirements for structural strength and safety are met.

Owner:CHINA MCC17 GRP

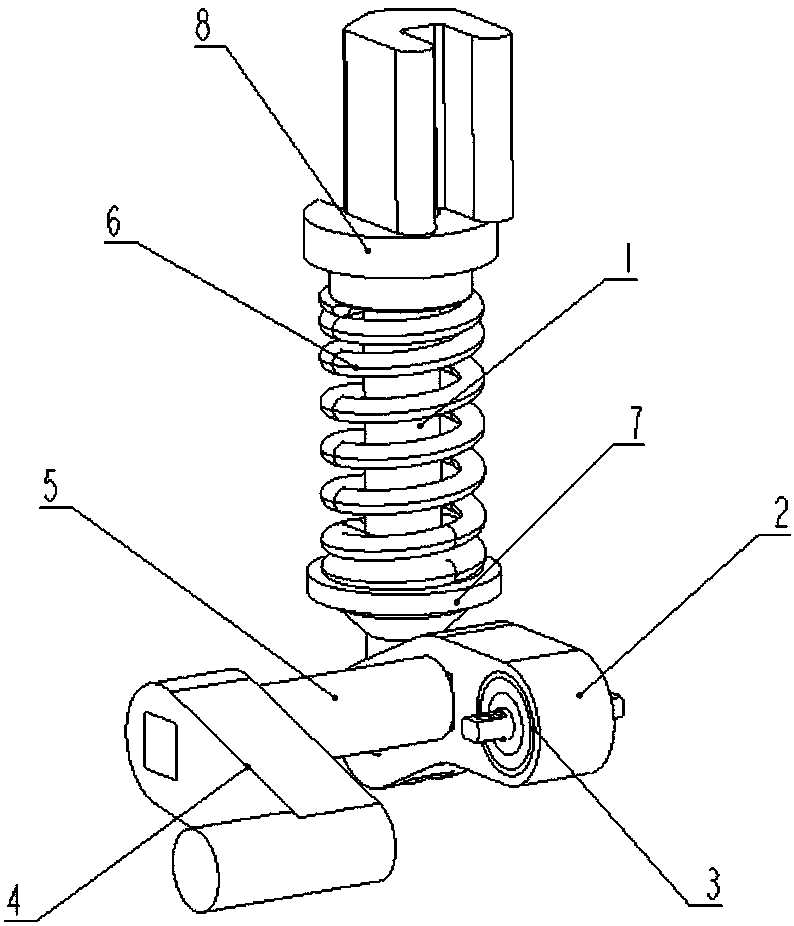

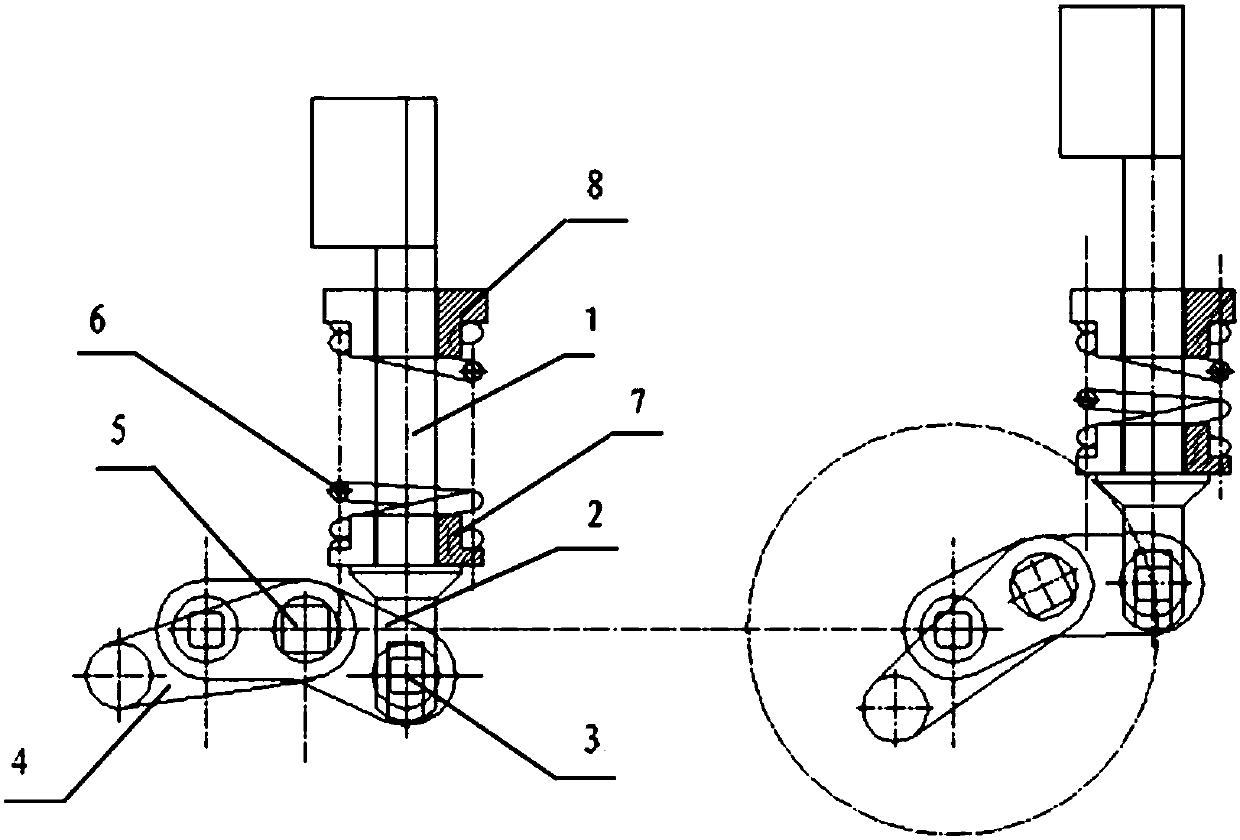

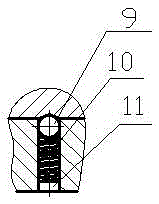

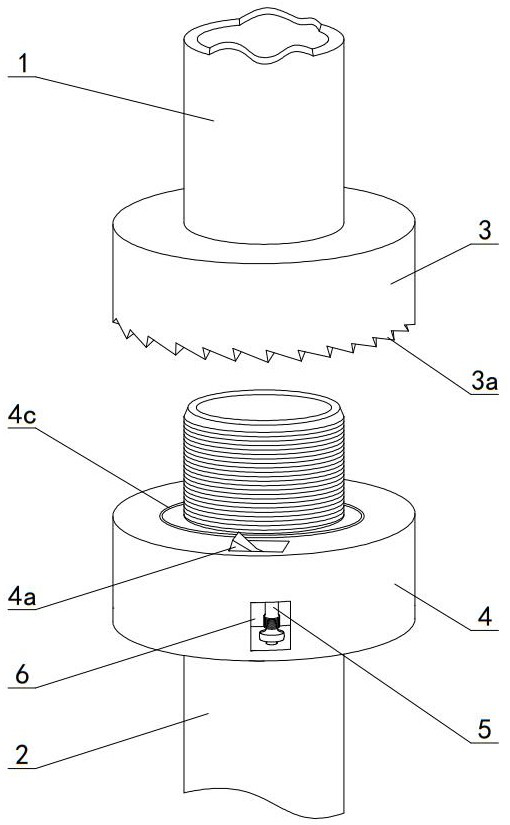

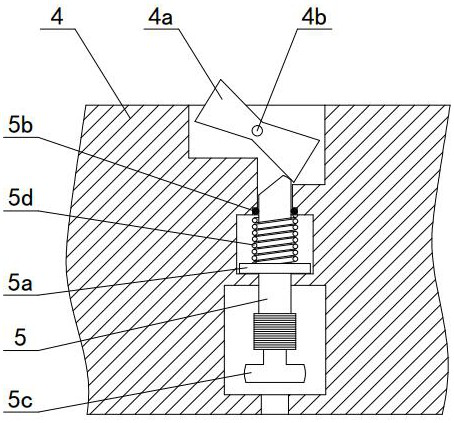

Locking device of machining tooling for cylinder body part holes

InactiveCN105750944ARealize the locking effectWork clamping meansPositioning apparatusPosition toleranceSet screw

An air cylinder body assembly is a key component consisting of an air cylinder body and a crankcase, and is an assembling substrate for all mechanisms and systems of an internal combustion engine; more parts of the air cylinder body assembly are used as components of a crankshaft connecting rod mechanism, an air distributing mechanism, a supplying system, a cooling system and a lubricating system. All holes, all surfaces and parts between the holes and the surfaces on the air cylinder body assembly have higher requirements on size, shape and position tolerance, and the machining difficulty is great. Style machining of the air cylinder body assembly adopts general technical equipment; a machining technical process comprises four stages, namely rough machining and semi-finish machining of the air cylinder body and crankcase parts, finish machining of air cylinder body assembly components and fine machining of key parts. Key links of the whole technical process are selection of technical standards at all machining stages, machining of the key parts (a spindle hole, a cylinder hole and a camshaft hole) and calculation of important dimensions (coordinate dimension of hole centre distances of a spindle hole, a cam hole and an idle wheel hole). The invention provides an important part for the machining tooling for the cylinder body part holes, which is used for locking the position of a feeding rack and mainly comprises a steel ball 9, a spring 10 and a locking screw 11.

Owner:NINGXIA JIHUA ENVIRONMENTAL SAFETY SCI & TECH CO LTD

Device for reinforcing concrete beam through fiber cloth and construction method thereof

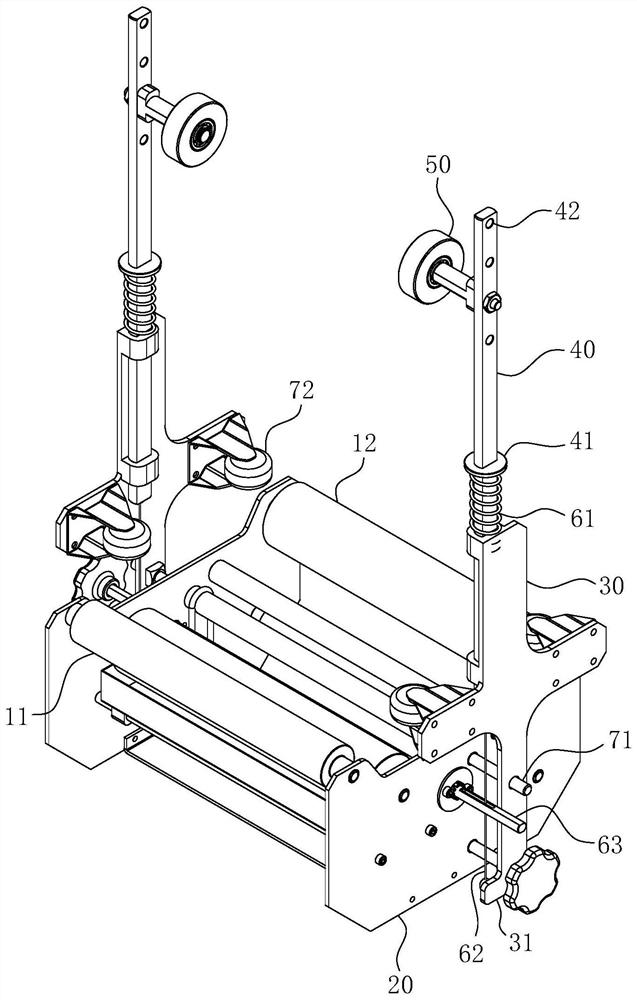

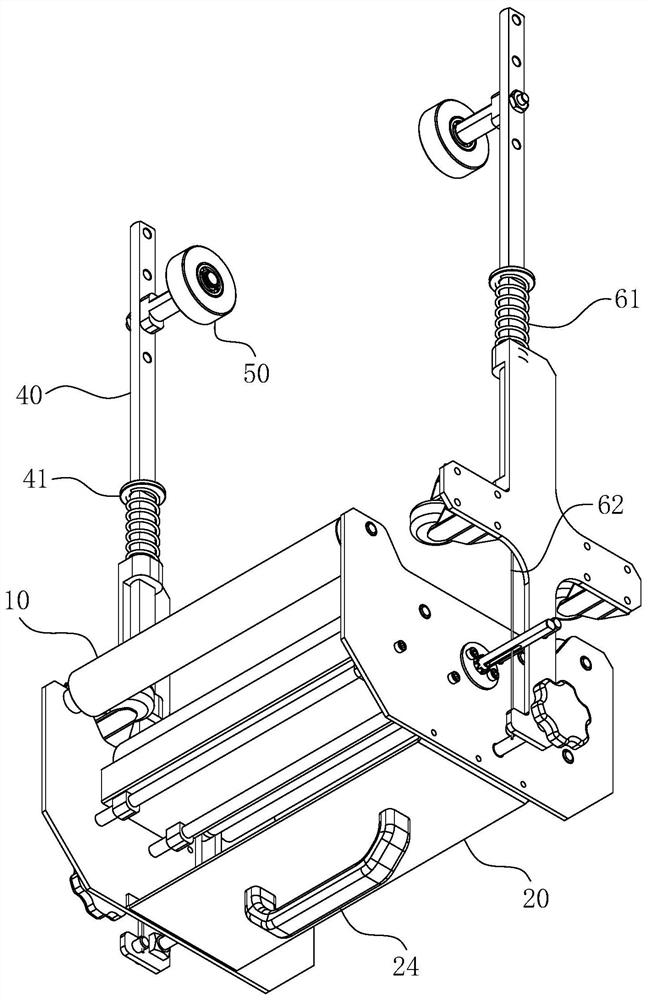

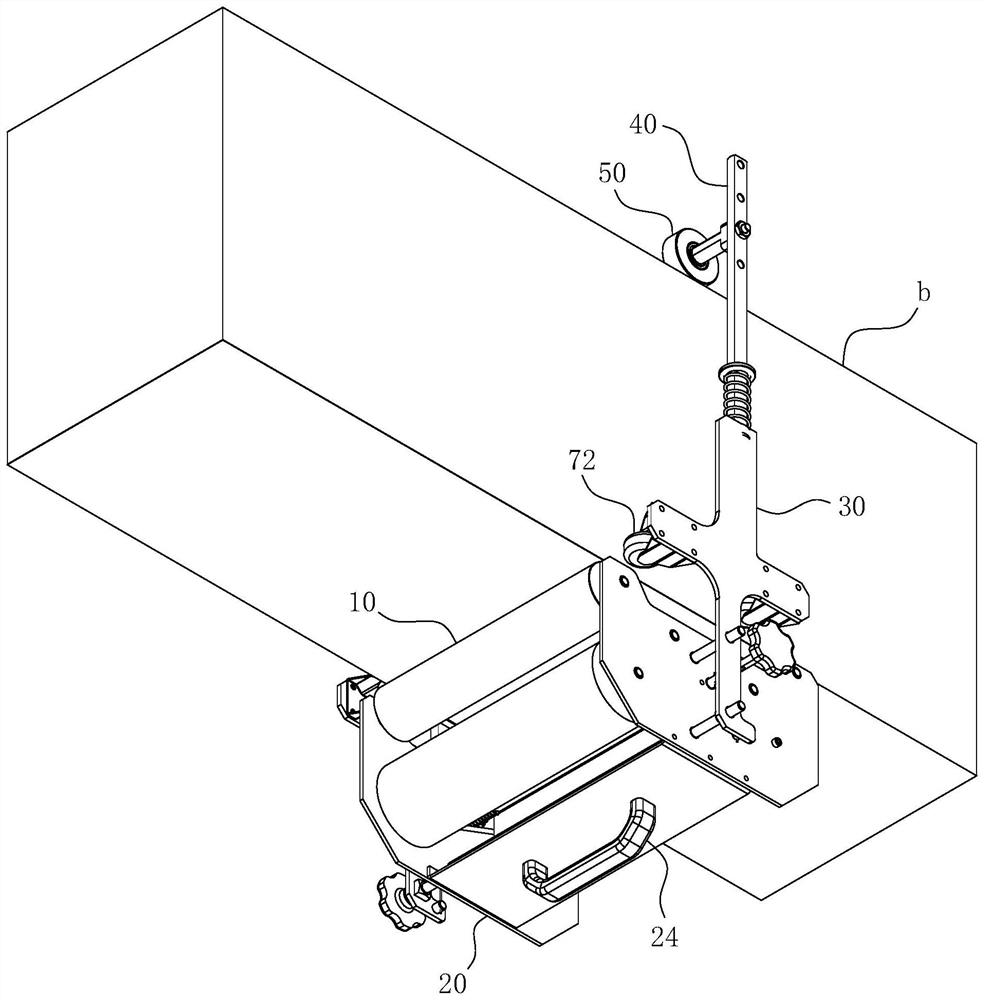

PendingCN113006526AReduce operating intensityPatch Quality AssuranceBuilding repairsFiberConcrete beams

The invention belongs to the technical field of civil engineering structure reinforcement and transformation construction, and particularly relates to a device for reinforcing a concrete beam through fiber cloth and a construction method thereof. The device comprises a roller frame provided with a pressing roller and adjusting supports, supporting rods are vertically arranged on the two sets of adjusting supports located on the two sides of the roller frame in a guiding fit mode, longitudinal adjusting wheels or limiting pins horizontally extend from the top ends of the supporting rods to the upper surface of the concrete beam, and therefore, the fiber cloth is pressed on the lower surface of the concrete beam through clamping cooperation of the longitudinal adjusting wheels or the limiting pins and the pressing rollers. The device further comprises a longitudinal adjusting assembly capable of enabling the supporting rod to generate vertical adjusting and positioning actions relative to the adjusting support. The device has the advantages of being easy and convenient to operate, high in reinforcing efficiency and good in finished product quality, time and labor are saved, and the actual construction period can be effectively shortened. The invention further provides a construction method applying the device, so that the purpose of on-site rapid construction of the fiber cloth is achieved specifically.

Owner:HEFEI UNIV +1

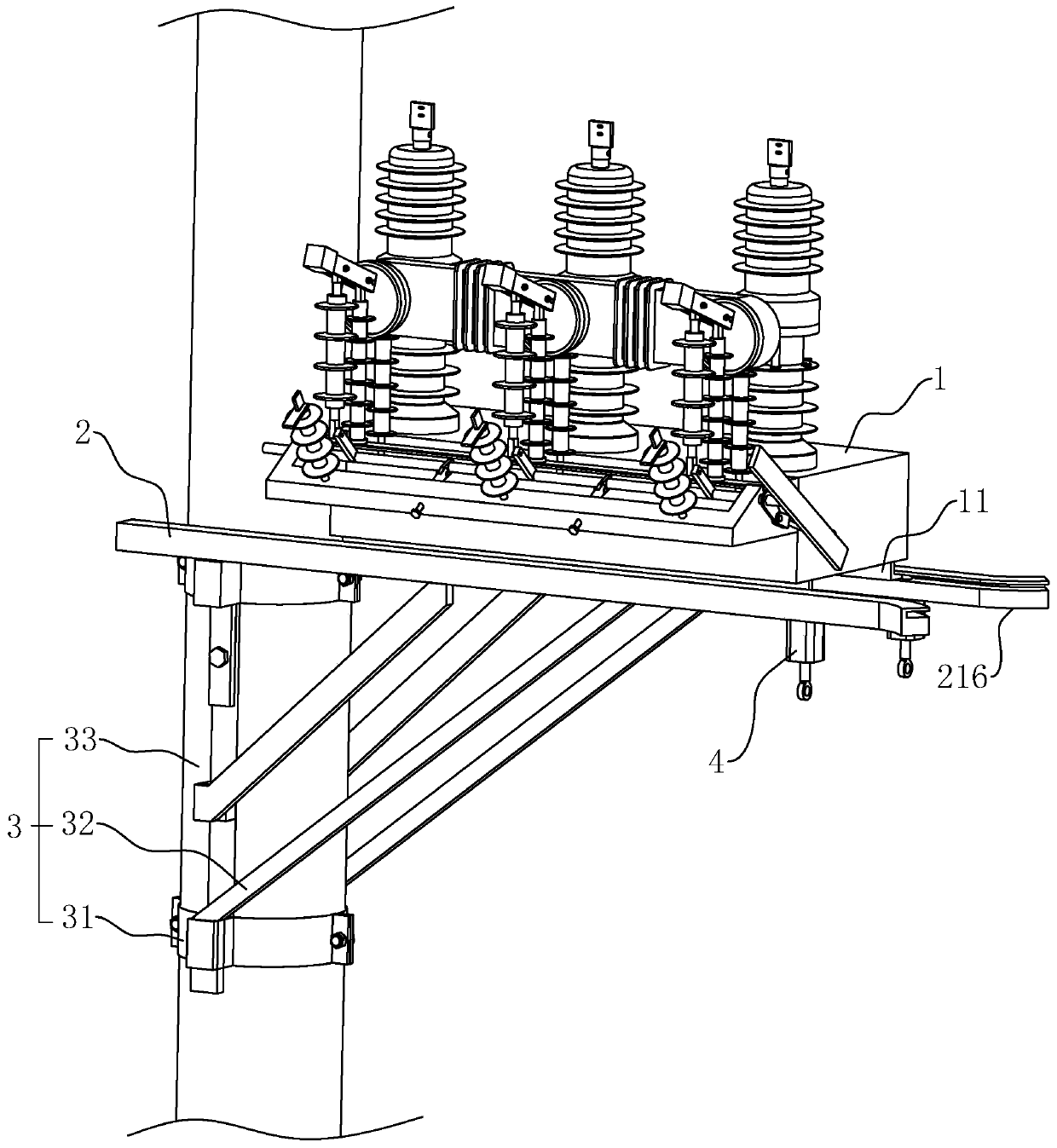

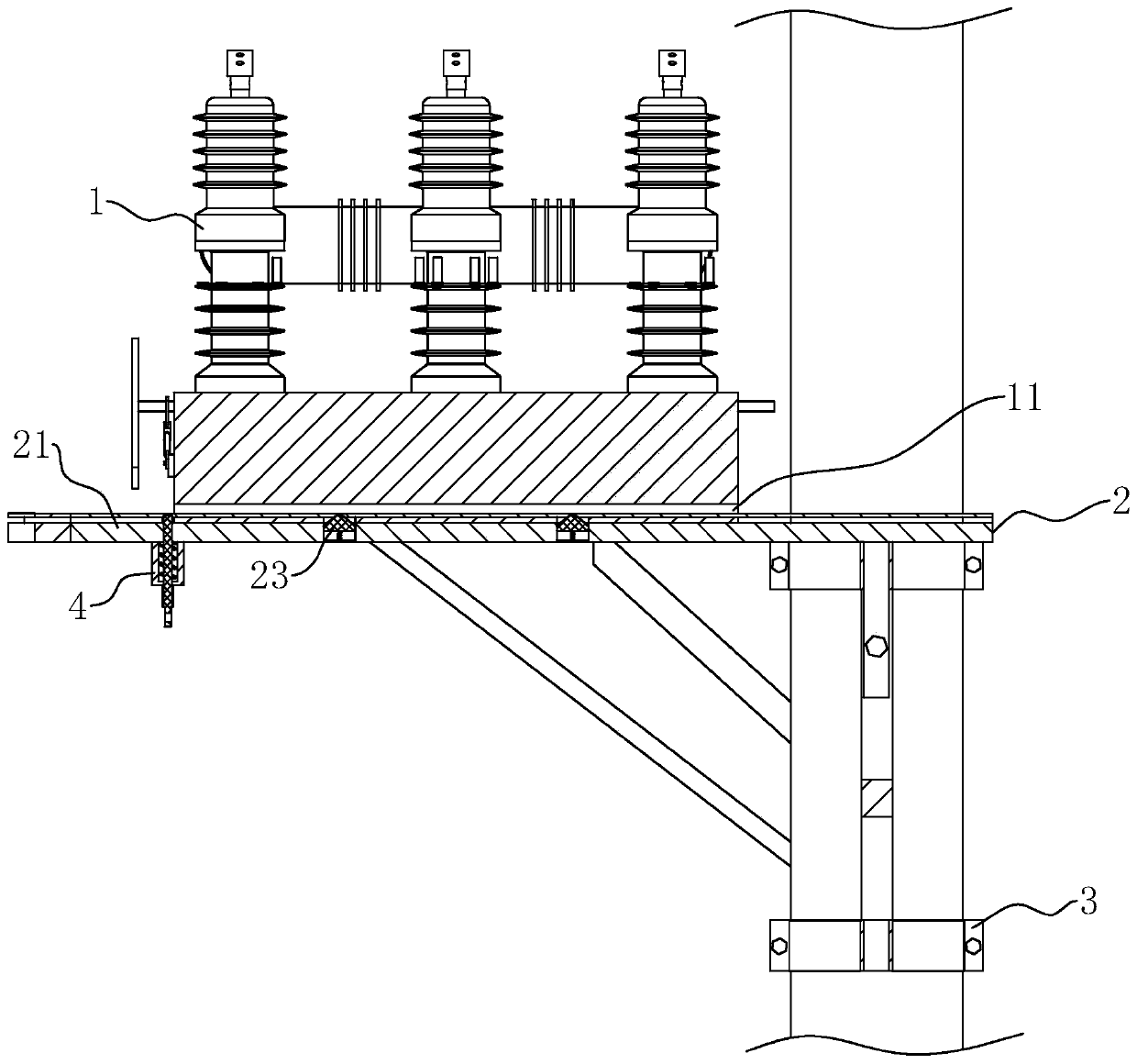

Outdoor pole-mounted vacuum circuit breaker

ActiveCN110349795ARealize the locking effectReduce labor intensityHigh-tension/heavy-dress switchesAir-break switchesVacuum interrupterEngineering

The invention discloses an outdoor pole-mounted vacuum circuit breaker, and relates to the technical field of vacuum circuit breakers. The vacuum circuit breaker comprises a vacuum circuit breaker body, a mounting assembly and a supporting assembly. The mounting assembly comprises mounting rods which are horizontally, symmetrically and fixedly arranged on a carrier; an opening is formed in the side surface of each mounting rod; the openings of the two mounting rods are arranged oppositely; mounting plates are fixedly arranged at the two sides of the bottom end of the vacuum circuit breaker body; the two mounting plates are respectively mounted in the openings of the two mounting rods in a sliding manner; mounting cavities are respectively formed in one side walls of the openings of the twomounting rods; elastic pieces are installed in the installation cavities and connected with lock rods, lock holes matched with the lock rods are formed in the two installation plates respectively, the elastic pieces drive the lock rods to be inserted into the lock holes, locking assemblies used for closing the openings are installed at the ends, away from the ends connected with the carrier, of the installation rods, and the supporting assemblies are connected with the installation rods. The vacuum circuit breaker is convenient to install and operate, improves the installation efficiency, andreduces the labor intensity of an operator.

Owner:威倍智能科技有限公司

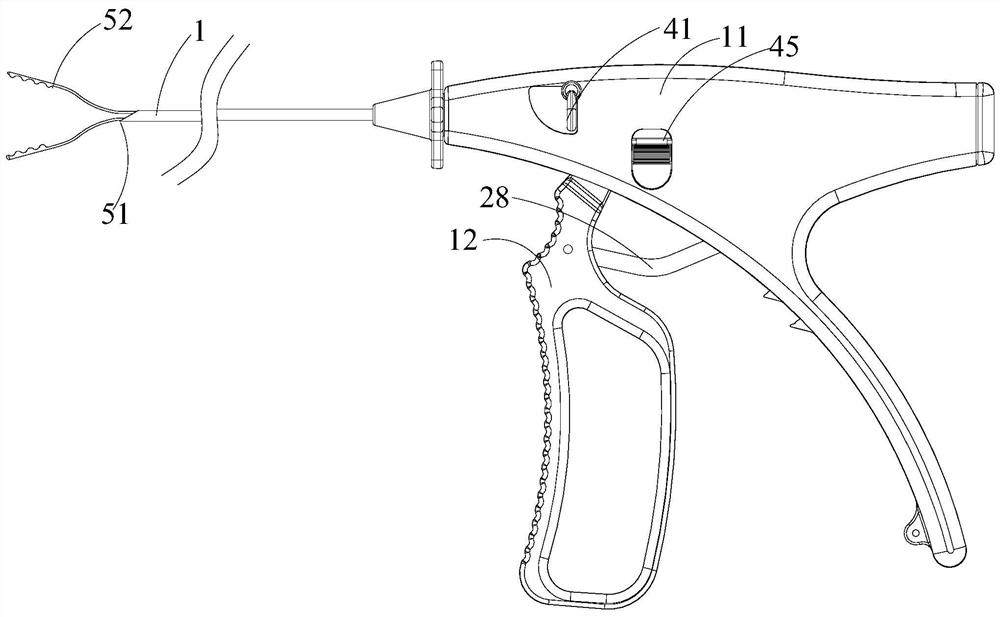

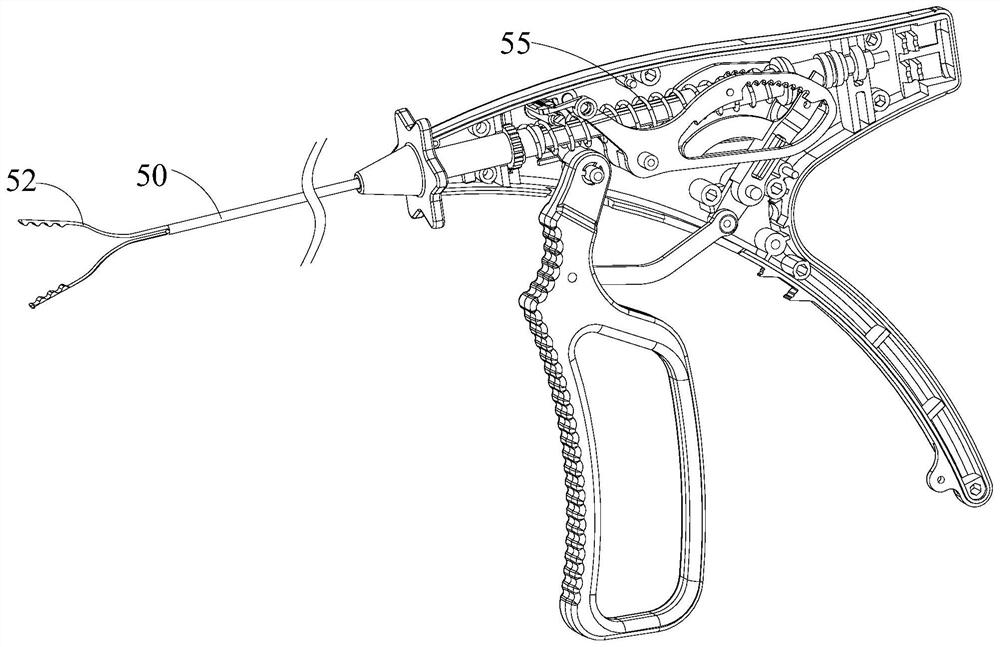

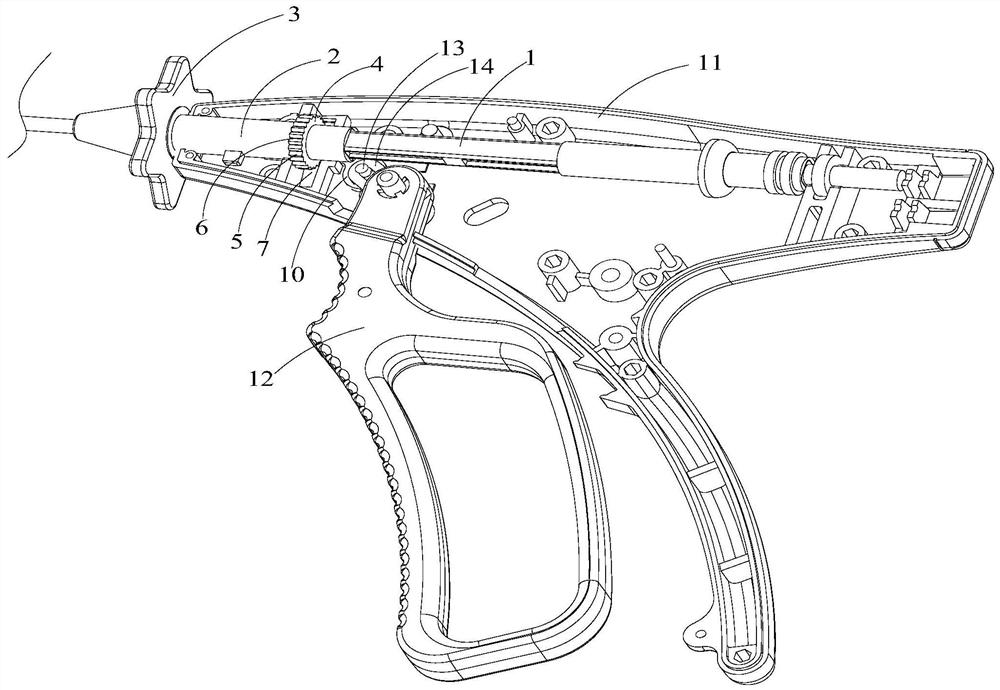

Puncture forceps and use method thereof

ActiveCN113558722AFast postoperative recoveryLower surgery costsSurgical needlesVaccination/ovulation diagnosticsForcepsBiomedical engineering

The invention discloses puncture forceps and a use method thereof. The puncture forceps comprise a device body, a forceps rod and a movable handle mathced with the device body; the forceps rod is provided with a hollow containing cavity penetrating through the two axial ends, and a forceps body suitable for axially moving relative to the forceps rod penetrates through the containing cavity; one end of the forceps rod away from the device body is provided with a conical tip; a pair of forceps wings suitable for being opened is arranged at the end, suitable for extending out of the conical tip, of the forceps body. The puncture forceps provided by the invention can be used to complete establishment of a channel and clamping of tissue at the same time through one instrument.

Owner:昊越(常州)医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com