Module assembly type building aluminum alloy formwork

An aluminum alloy formwork and assembled technology, which is applied in the direction of formwork/formwork components, construction, formwork/formwork/work frame connectors, etc., can solve the inconvenience of disassembly and installation of aluminum alloy formwork and reduce the scope of use of aluminum alloy formwork , Reduce work efficiency and other issues, to avoid the angle cannot be converted, avoid the reduction of the scope of use, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

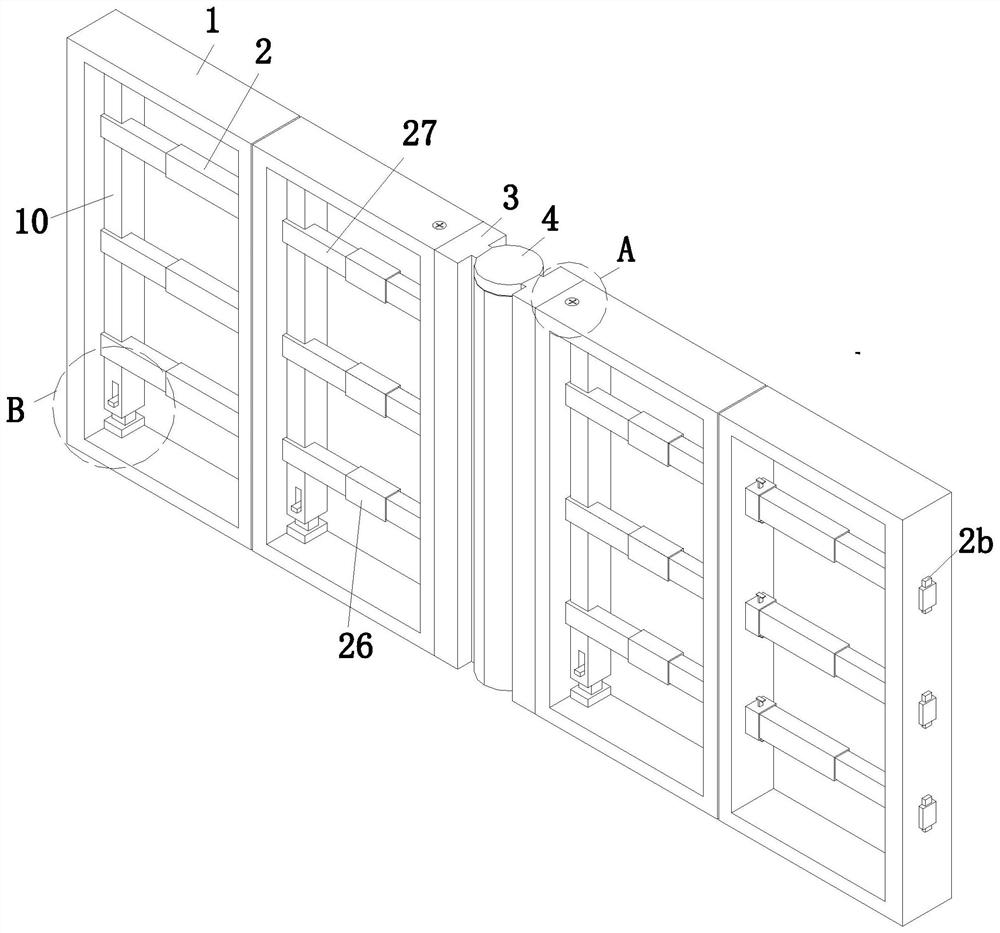

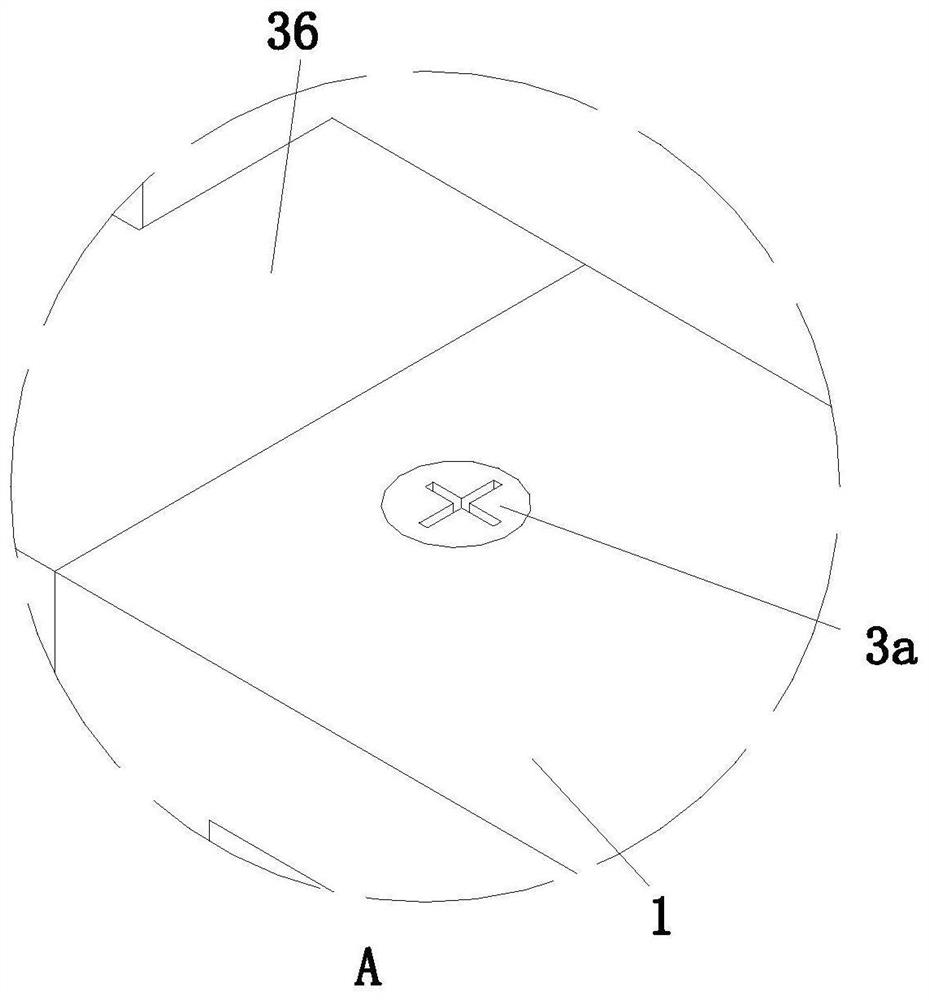

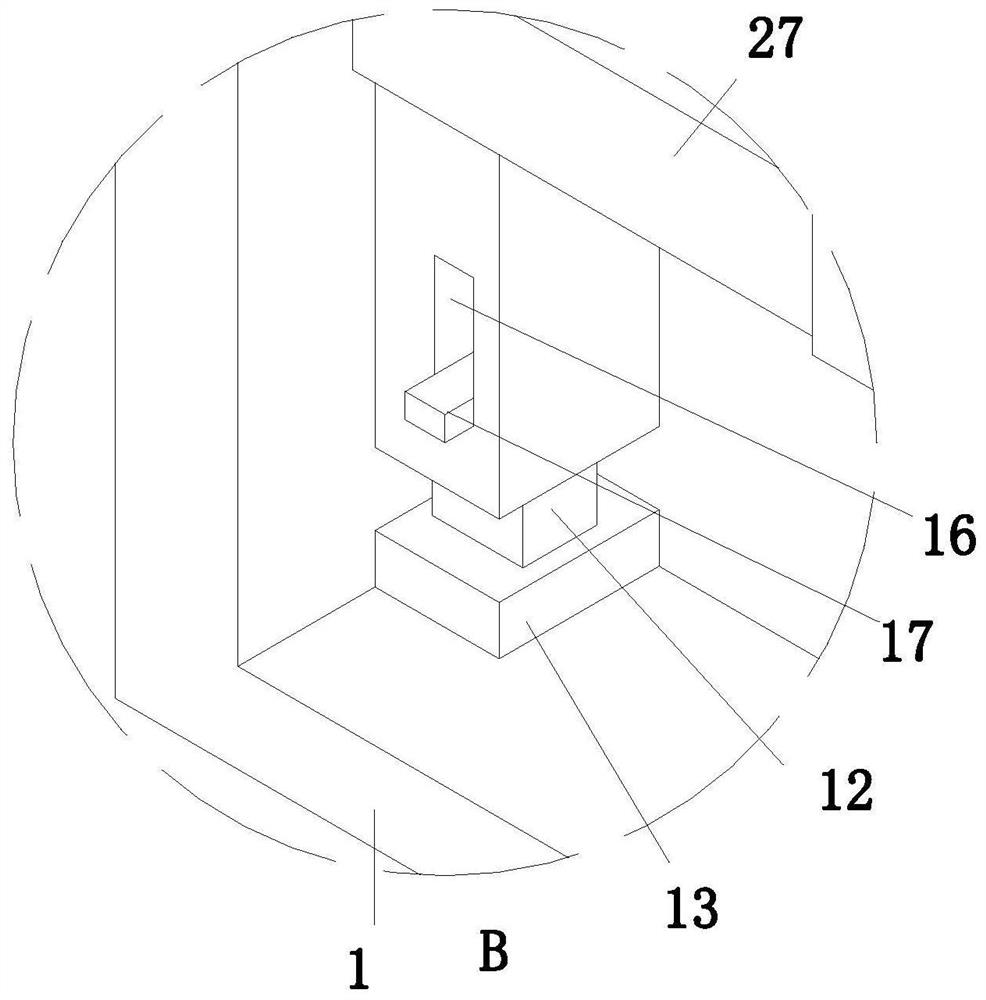

[0029] Such as Figure 1 to Figure 9 As shown, a modular assembled building aluminum alloy formwork includes a unit module 1, a connection mechanism 2, an angle adjustment mechanism 3 and a locking mechanism 4, and every two unit modules 1 are connected by a connection mechanism 2, Every two unit modules 1 form a group, the left and right two groups of unit modules 1 are symmetrically arranged, and the left and right groups of unit modules 1 are connected through an angle adjustment mechanism 3, and the angle adjustment mechanism 3 is provided with a locking mechanism 4;

[0030] The inner walls of the unit modules 1 are all provided with reinforcing plates 10, and the reinforcing plates 10 in the unit modules 1 on both sides of the hollow column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com