Crankshaft position limiting system after flameout of automobile engine

A technology for the position of automobile engine and crankshaft, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as the inability to perform flexible control in the meshing process and damage to the engine flywheel teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

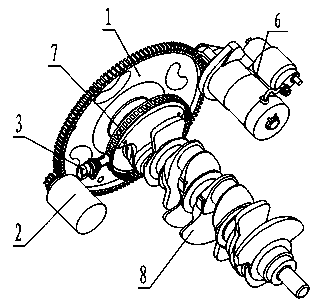

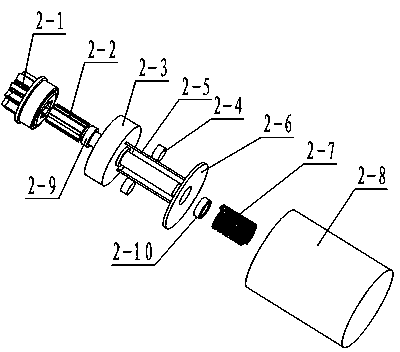

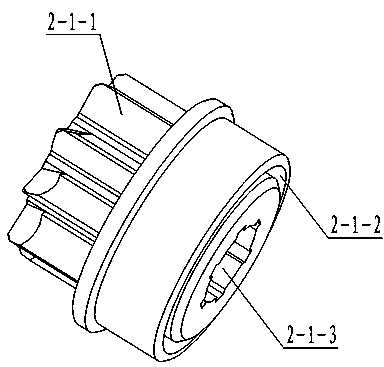

[0026] See Figure 1, figure 2 , the present invention includes engine flywheel 1, crankshaft position locking mechanism 2, crankshaft position sensor 3, crankshaft signal plate 7 and engine ECU 4, and described crankshaft position locking mechanism 2 includes locking gear 2-1, transmission shaft 2-2 , locking wheel 2-3, electromagnetic valve 2-4, traction push rod 2-5, traction disc 2-6, return spring 2-7 and body shell 2-8, and described locking gear 2-1 is installed on The front end of the transmission shaft 2-2, the transmission shaft 2-2 is assembled with the locking wheel 2-3, the electromagnetic valve 2-4 is arranged in front of the traction disc 2-6, and the traction disc 2-6 is connected with the traction pusher The rear end of the rod 2-5 is fixedly assembled, the front end of the traction push rod 2-5 passes through the locking wheel 2-3 and is fitted with the locking gear 2-1, and the return spring 2-7 is set on the body shell 2 -8 in the lumen.

[0027] see im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com