Hot air cyclone drying equipment and its method for dehydration and drying of agricultural by-products

A technology for drying equipment and agricultural and sideline products, which is applied in the direction of lighting and heating equipment, drying gas arrangement, local agitation dryer, etc. It can solve the problems of uneven drying speed of materials, low product quality, small processing capacity, etc., and achieve the goal of maintaining proper Odor, competitiveness improvement, energy consumption reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples. It should be understood that the examples are used to understand the present invention, but not to limit the present invention.

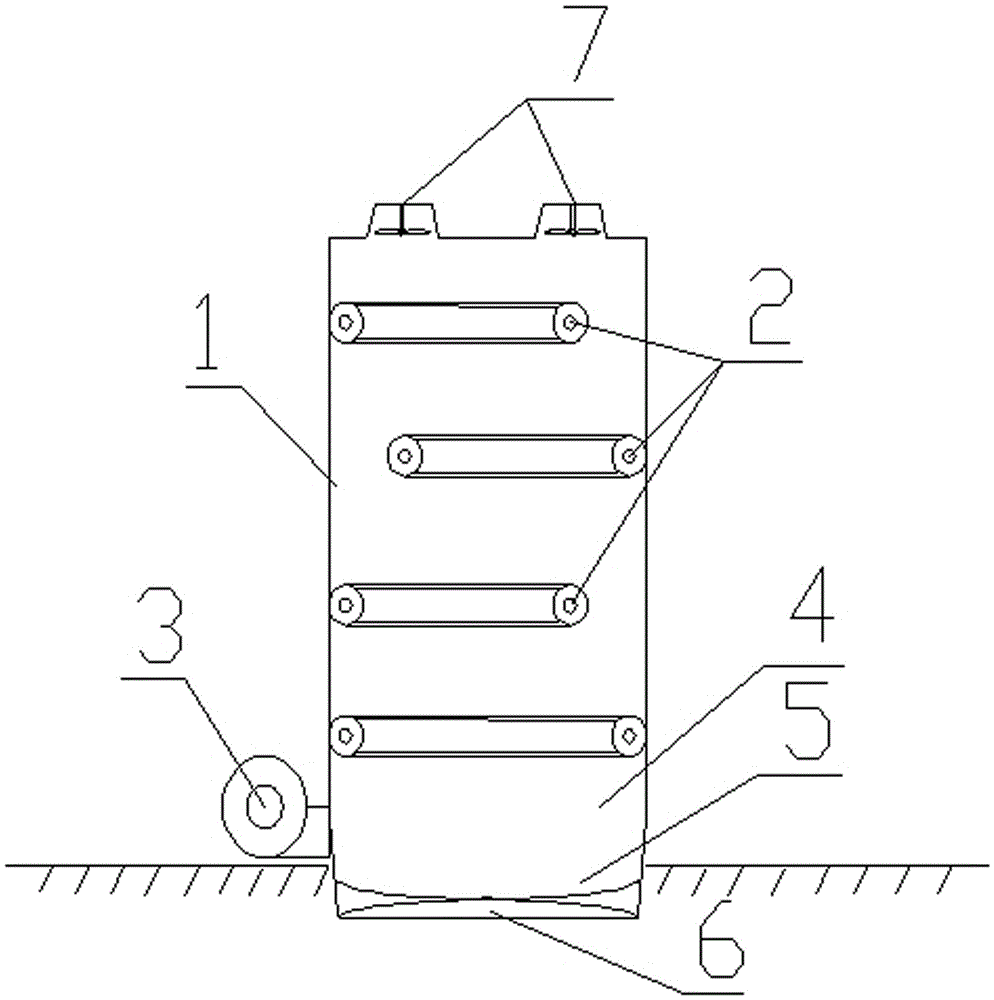

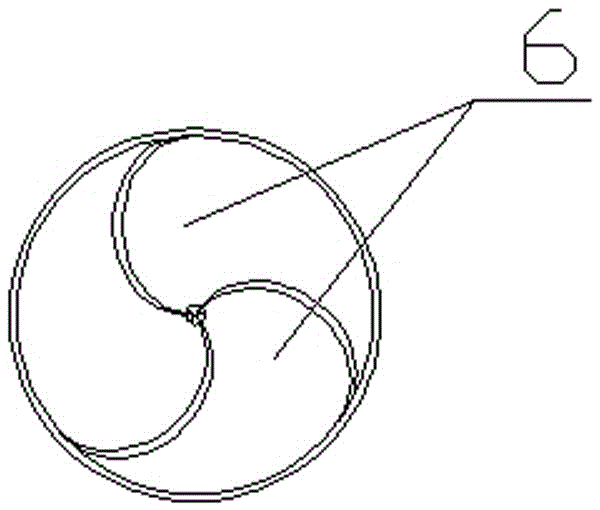

[0023] Such as figure 1 As shown above, a hot air cyclone drying equipment includes a complete machine shell 1 and a plurality of vents 7 arranged on the top of the complete machine shell, and a top-down three-layer loading turnover device is arranged on the inside of the complete machine shell 1 2. There is an air chamber under the loading flap device 2, and the air chamber is connected to the fan 3 on the outside of the machine casing through the air outlet. The air guiding chamber 5 takes the ground level as the interface, the swirling air guiding chamber 5 is located below the ground level, the height of the air distribution chamber is 1.5 meters, and the height of the swirling air guiding chamber is 0.45 meters.

[0024] The division of the air chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com