A vertical ultrasonic paper thickness measuring device

An ultrasonic and thickness measurement technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems such as very high surface precision requirements for winding paper, ultrasonic can not achieve high-precision measurement, and it is difficult to promote and use on a large scale. , to achieve the effects of improving detection accuracy, low production cost, and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

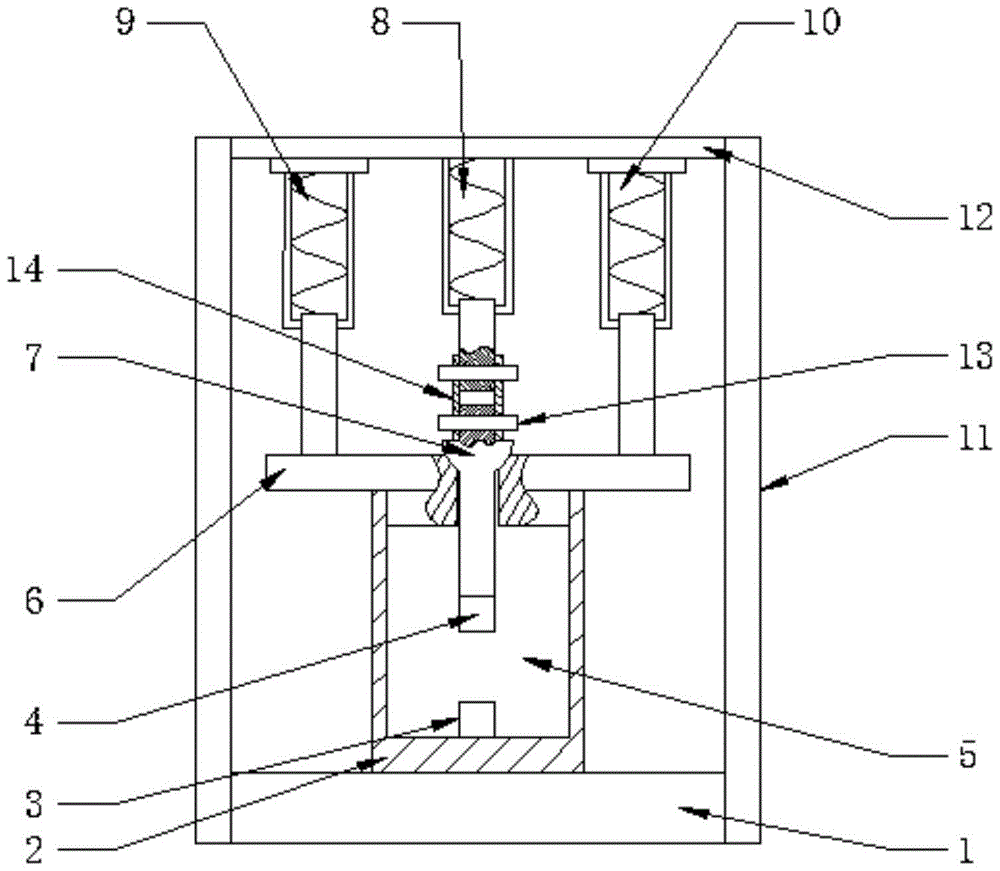

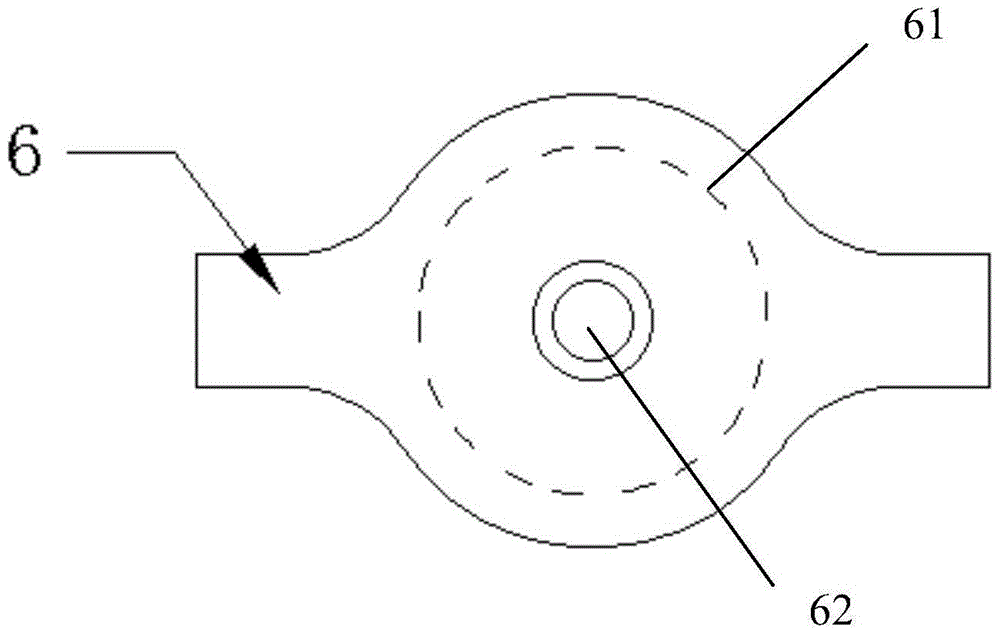

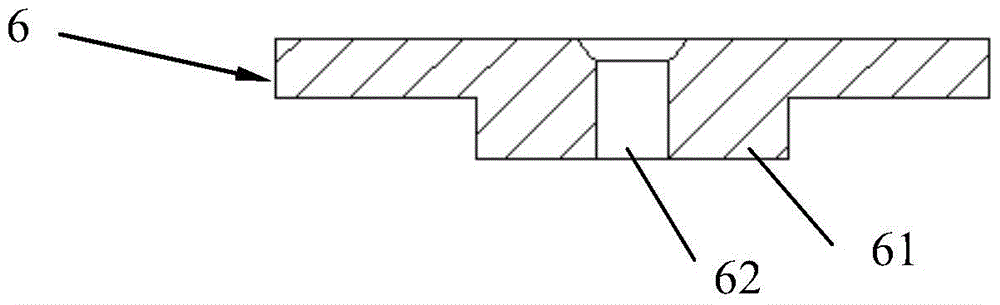

[0017] The vertical ultrasonic paper thickness measuring device designed by the present invention (abbreviation device, see Figure 1-4 ), characterized in that the device includes: paper holder 1, tank body 2, upper ultrasonic probe 4, lower ultrasonic probe 3, tank upper cover 6, hemispherical valve 7, No. 1 electromagnet 8, No. 2 electromagnet 9, No. 3 electromagnet 10, frame bracket 11, frame upper frame 12, fixed pin 13 and sleeve pipe 14, this device is a vertical frame structure as a whole, and its upper, lower, left and right are frame upper frame 12, paper holder 1 and The two frame supports 11 are connected as a whole, and there are no baffles in the front and rear; the paper holder 1 is connected with the frame holders 11 on both sides, and the tank body 2 is placed on the paper holder 1; the lower ultrasonic probe 3 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com