Unbalance amount measuring device and method thereof

A measurement device and measurement method technology, applied in the direction of measurement device, static/dynamic balance test, machine/structural component test, etc. problems, to achieve the effect of reducing adverse effects, improving the accuracy of test data, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

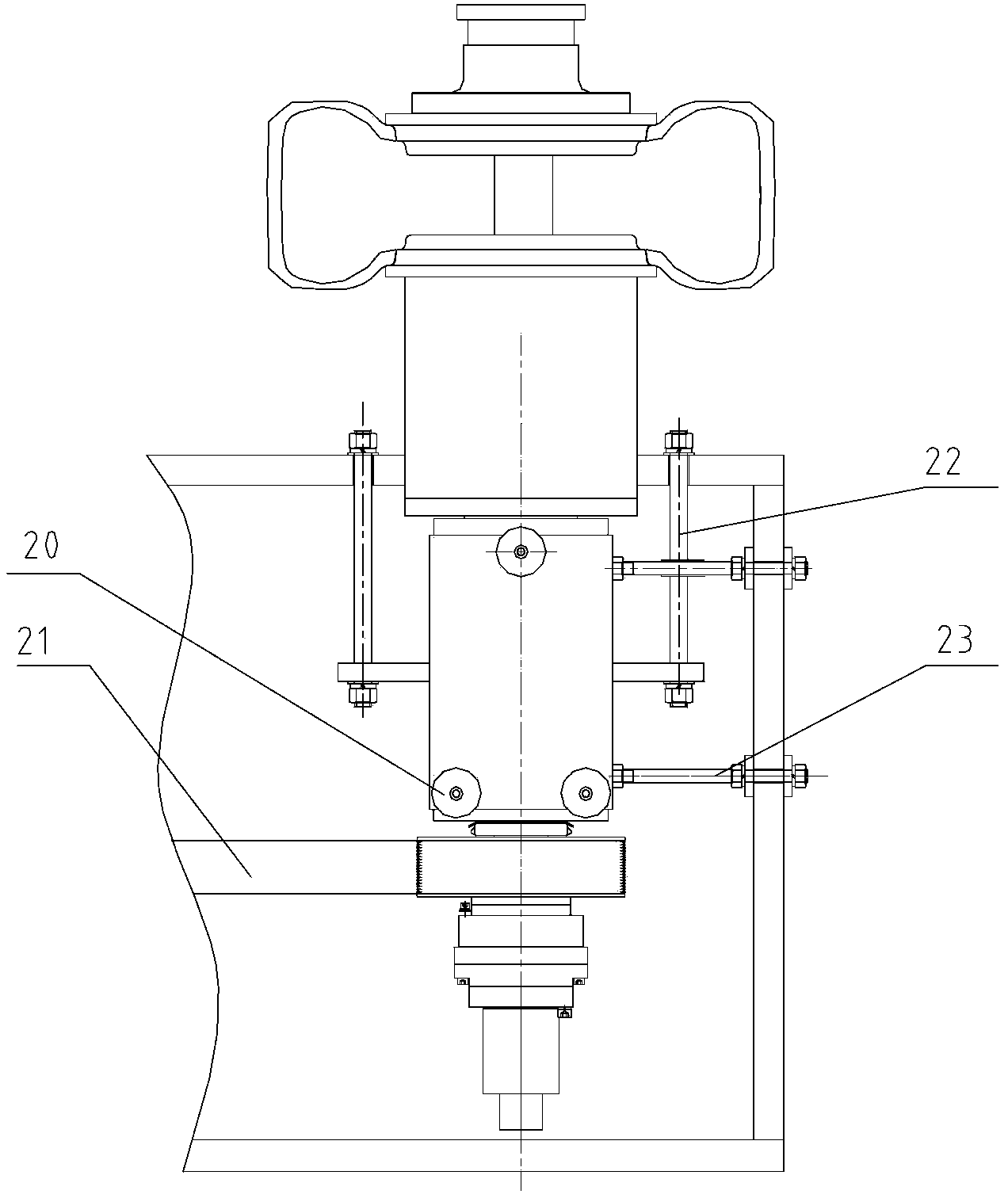

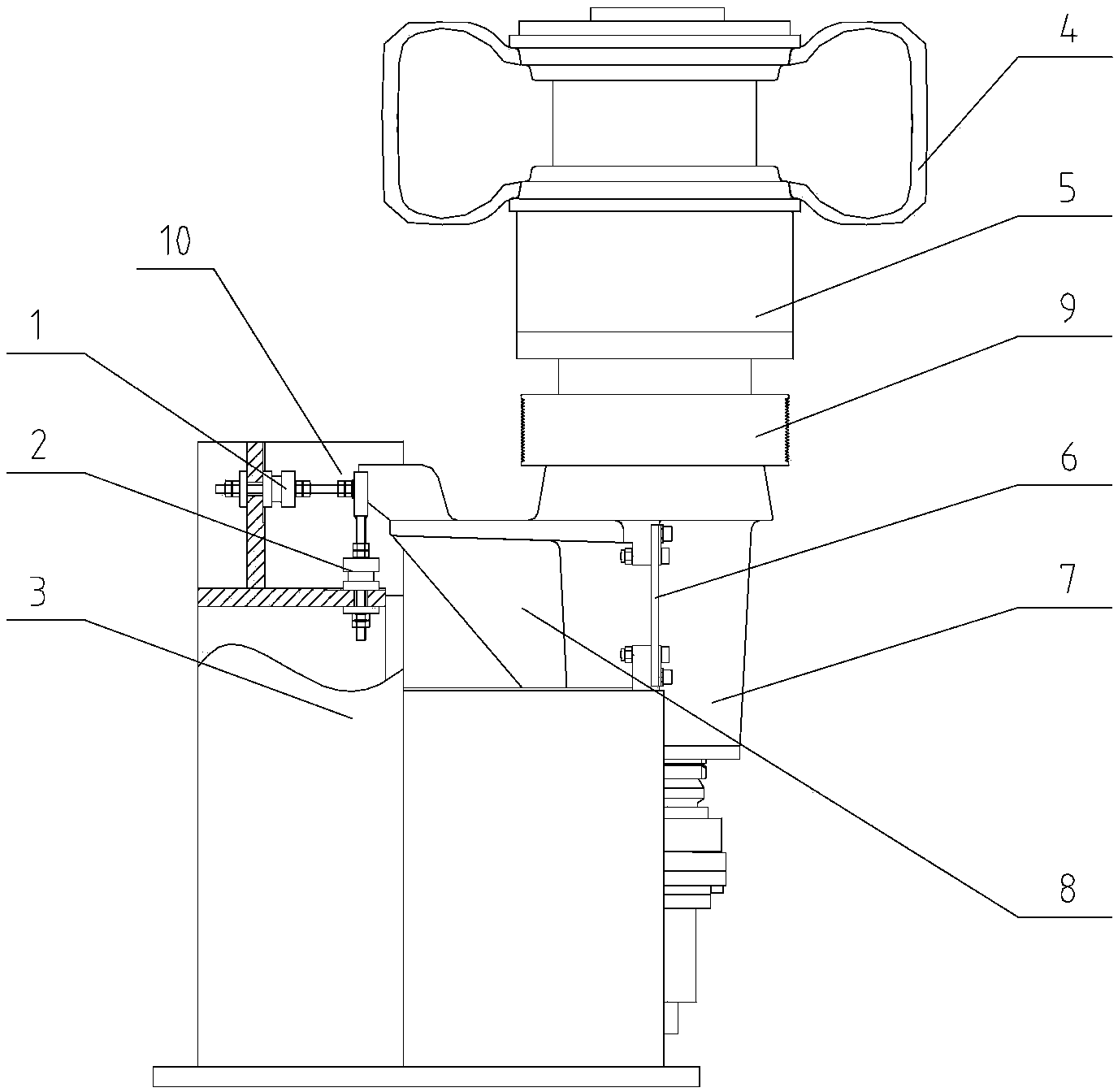

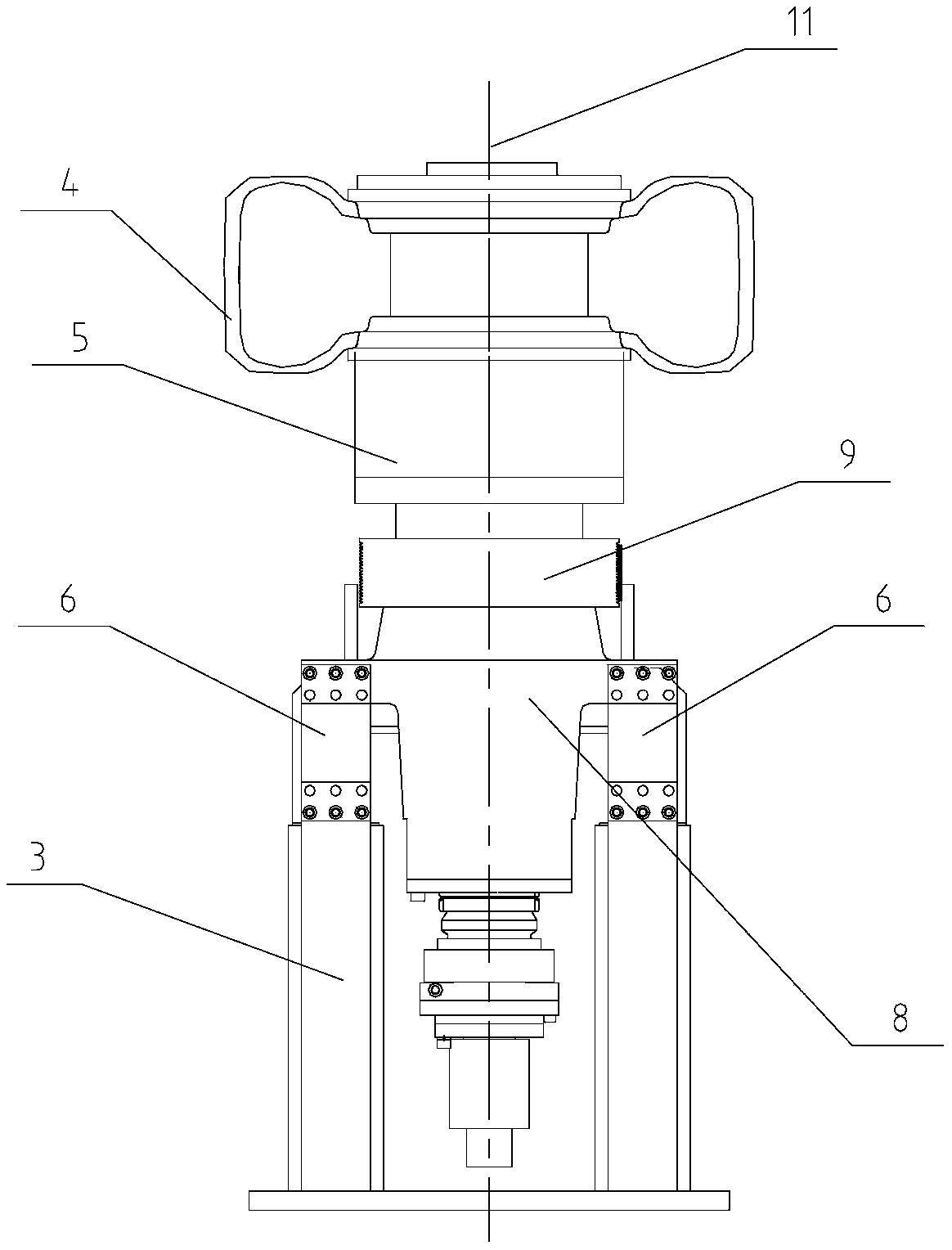

[0045] Example 1, such as Figure 2 to Figure 3 As shown, the described measuring device for unbalance mainly includes:

[0046] A vibrator 6 and a sensor group 10 are arranged between the fixed seat 3 and the rotating shaft housing 7, wherein,

[0047] The vibrating member 6 has a centrally symmetrical overall planar structure. In this embodiment, the vibrating member 6 is a rectangular flat plate structure, and one end of the vibrating member 6 along the direction of extending the axial center line 11 of the rotating shaft 5 is connected to the fixed seat 3 (this end is a fixed connection and there should be no vibration), and the other end is connected to the extension part 8 of the rotating shaft housing.

[0048] The sensor group 10 has a horizontal sensor 1 and a vertical sensor 2, the vertical sensor 2 is arranged parallel to the vibrating element 6, and the horizontal sensor 1 is perpendicular to the plane where the vibrating element 6 is located.

[0049] One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com