Leak detection method of battery module and the battery module

An inspection method and battery module technology, applied in battery/battery leakage test, secondary battery, battery pack components, etc., can solve problems such as electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, an embodiment of the present invention will be described in detail with reference to the drawings.

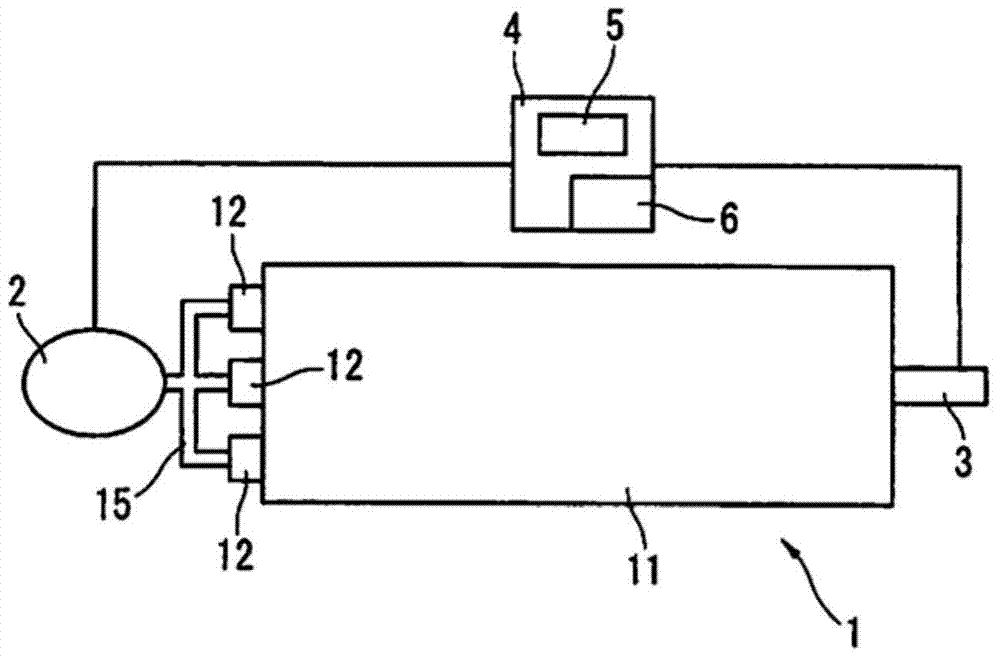

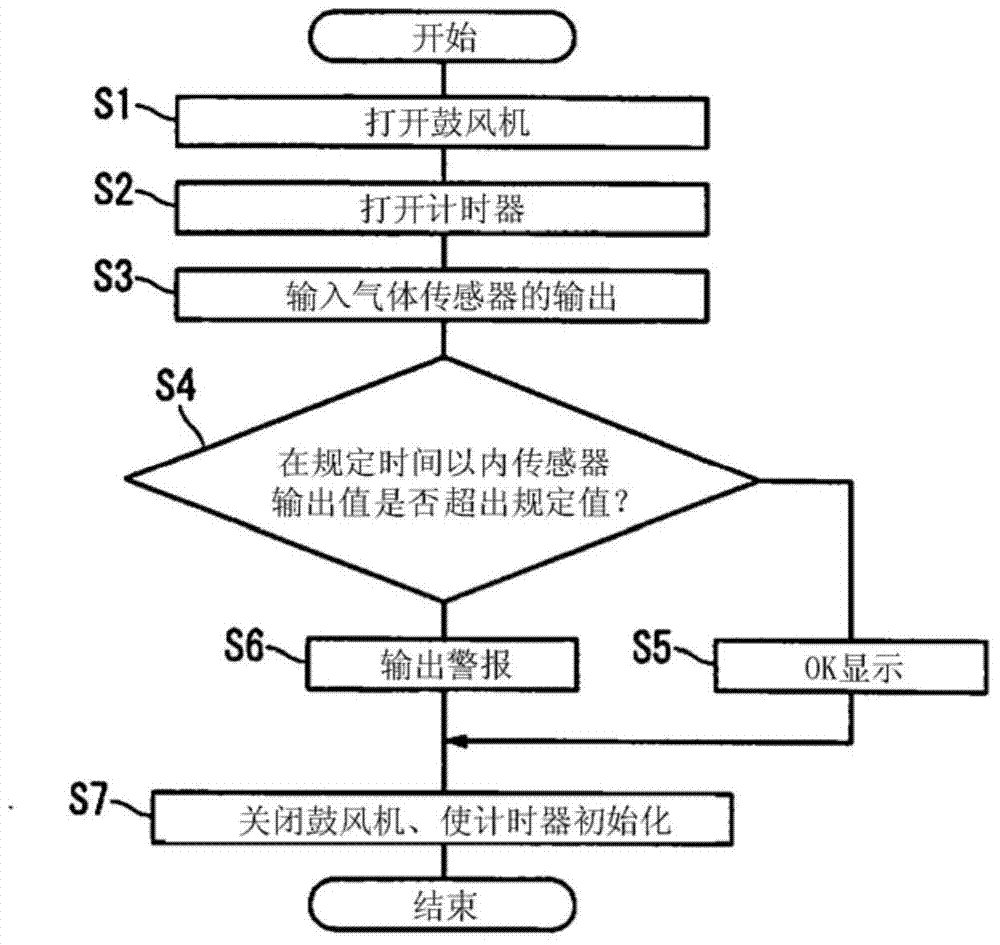

[0039] figure 1 It is an explanatory diagram showing an embodiment of the liquid leakage inspection method of the present invention, and the blower 2 and the gas sensor 3 are arranged to face each other, and the blower 2 forces the battery module 1 to be inspected on the liquid leakage inspection table in the production line. Air is introduced into the air, and the gas sensor 3 detects gas components caused by leakage of the electrolytic solution. The blower 2 and the gas sensor 3 described above are connected to a controller 4 which performs a liquid leakage check. The controller 4 includes a display 5 for displaying the result of the liquid leakage inspection, and a notifier 6 for sounding an alarm when a liquid leakage is detected.

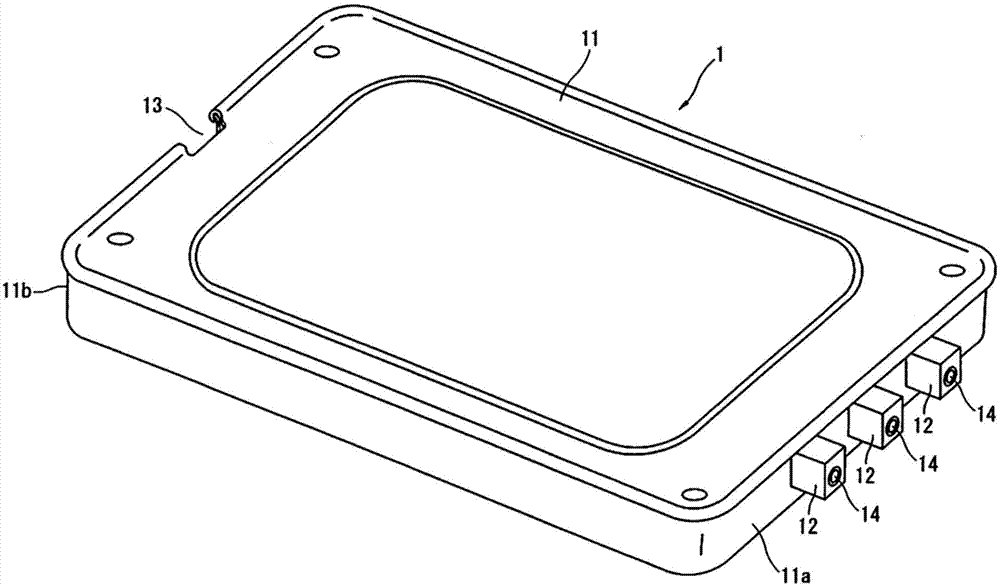

[0040] Such as image 3 As shown, the above-mentioned battery module 1 is, for example, stacked and housed in four flat rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com