Automatic sampler

A technology of automatic sample injection and container, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of high cost of use and maintenance, large space, occupation, etc., so as to reduce the cost of manufacturing and maintenance, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

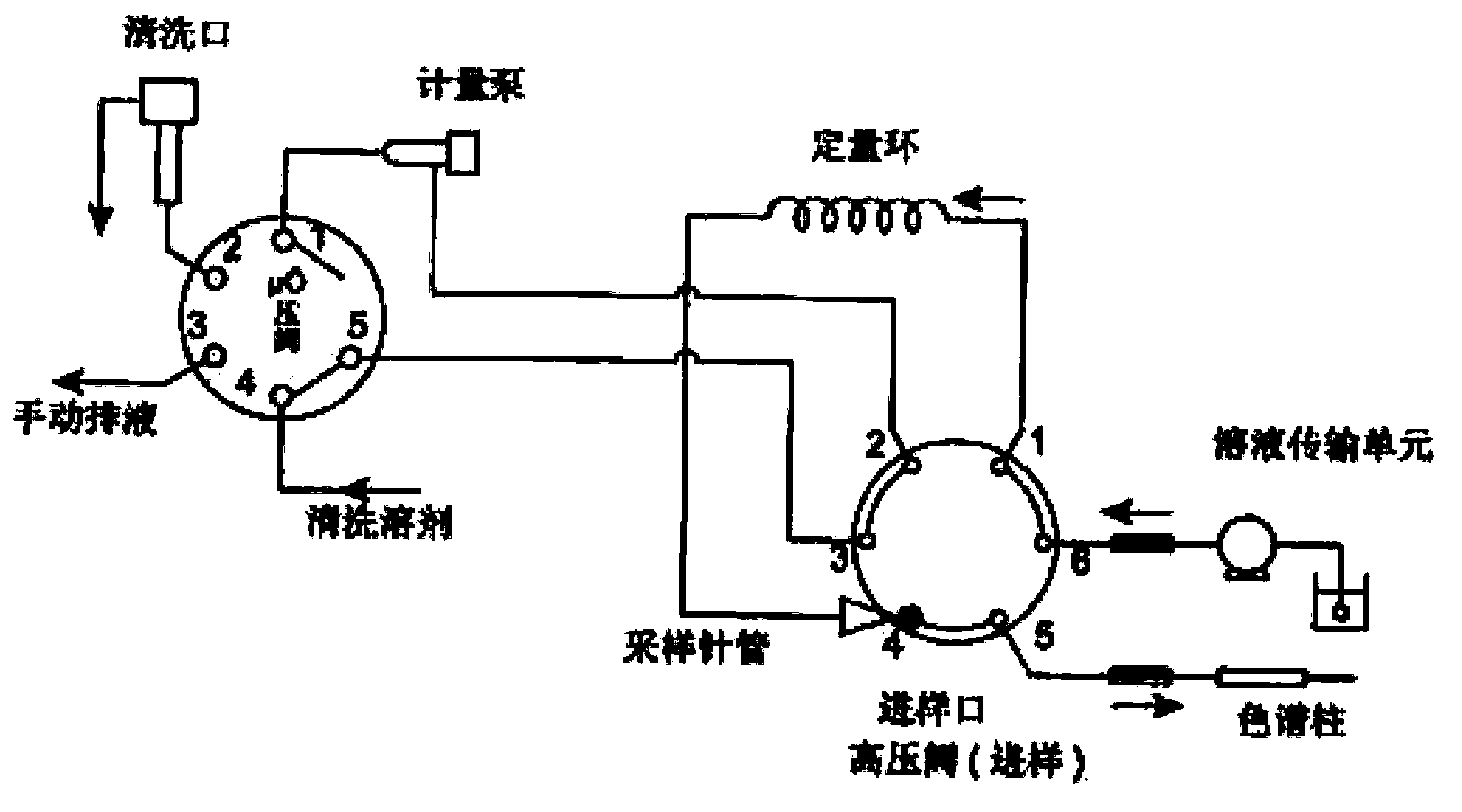

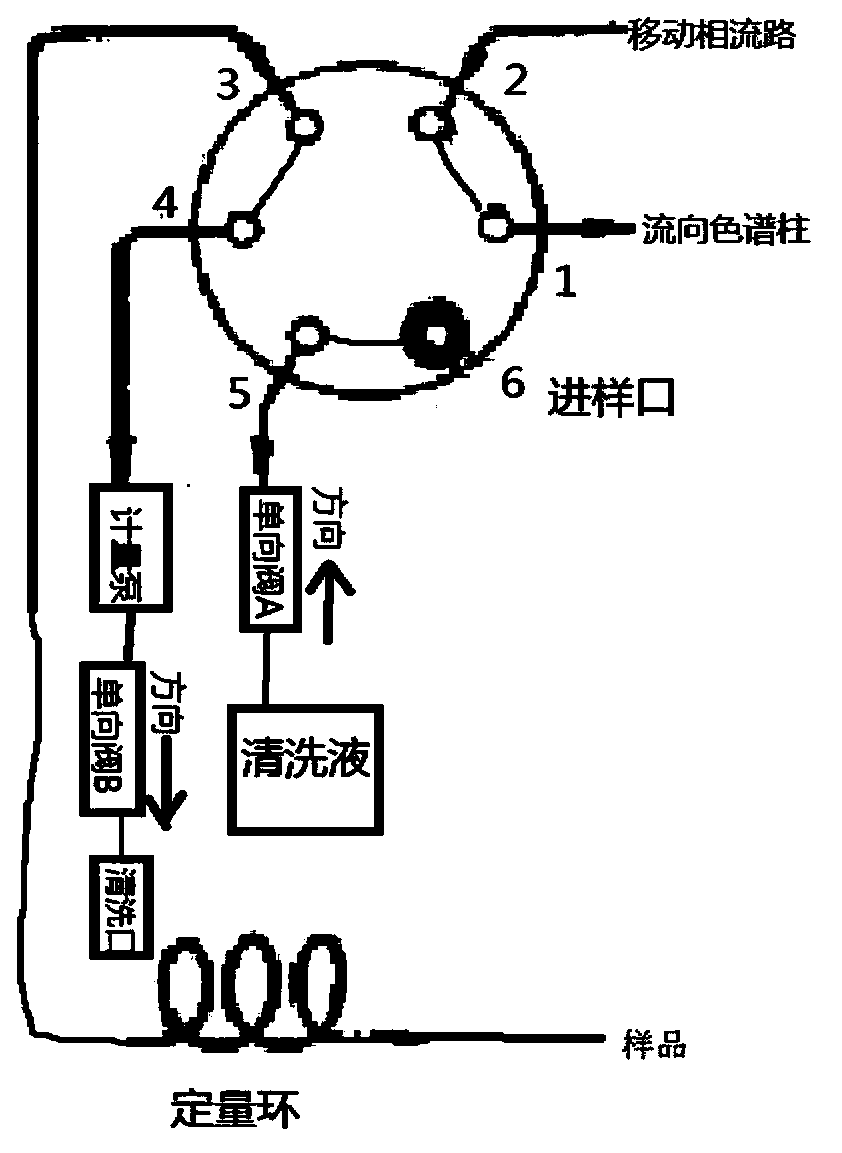

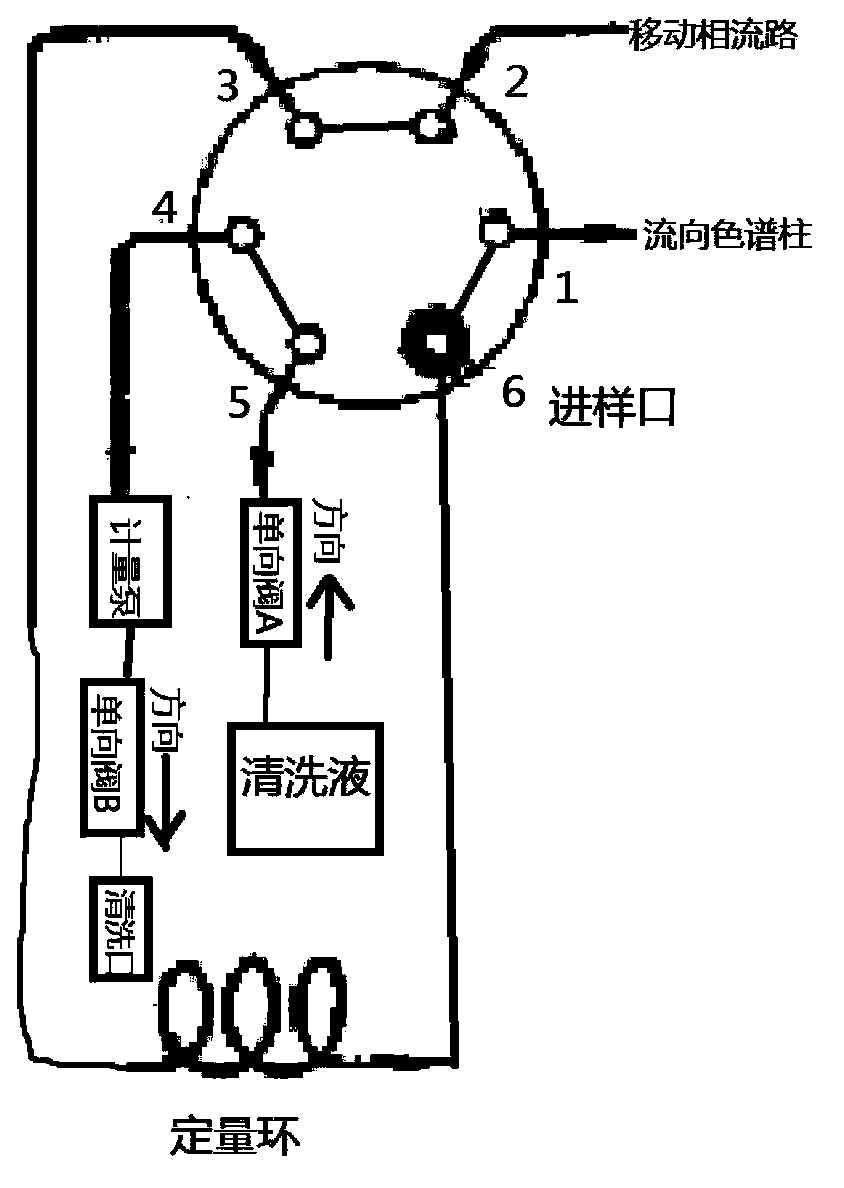

[0010] Refer to the attached Figure 2a-2d The sampling process of the autosampler according to the embodiment of the present invention will be described.

[0011] For convenience, the ports of the switching valve are numbered 1-6 in sequence. Port 1 is connected to the chromatographic column of the liquid phase analyzer, port 2 is connected to the high-pressure mobile phase flow path, port 3 is connected to the quantitative loop, port 4 is connected to the metering pump, and port 5 Connect the outlet of one-way valve A, and port 6 is the sample inlet. Such as Figure 2a As shown, at this time, ports 1 and 2, 3 and 4, and 5 and 6 of the switching valve are connected respectively, and the sampling needle is inserted into the sample bottle, and the metering pump starts to inhale. The flow direction is indicated by the arrows, from the sampling needle to the loop, through ports 3 and 4, where the metering pump draws in the sample.

[0012] Next, sample injection and delivery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com