Single-spindle single control system applied to air covered yarn machine and control method

The technology of covering machine and air bag is applied in the field of single-spindle and single-control control system, which can solve the problems of many leaks, unable to meet the flexible production requirements of small batch, multi-variety and high-tech content of manufacturers, and low production efficiency. Achieve the effect of improving the speed of data processing, enhancing general scalability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

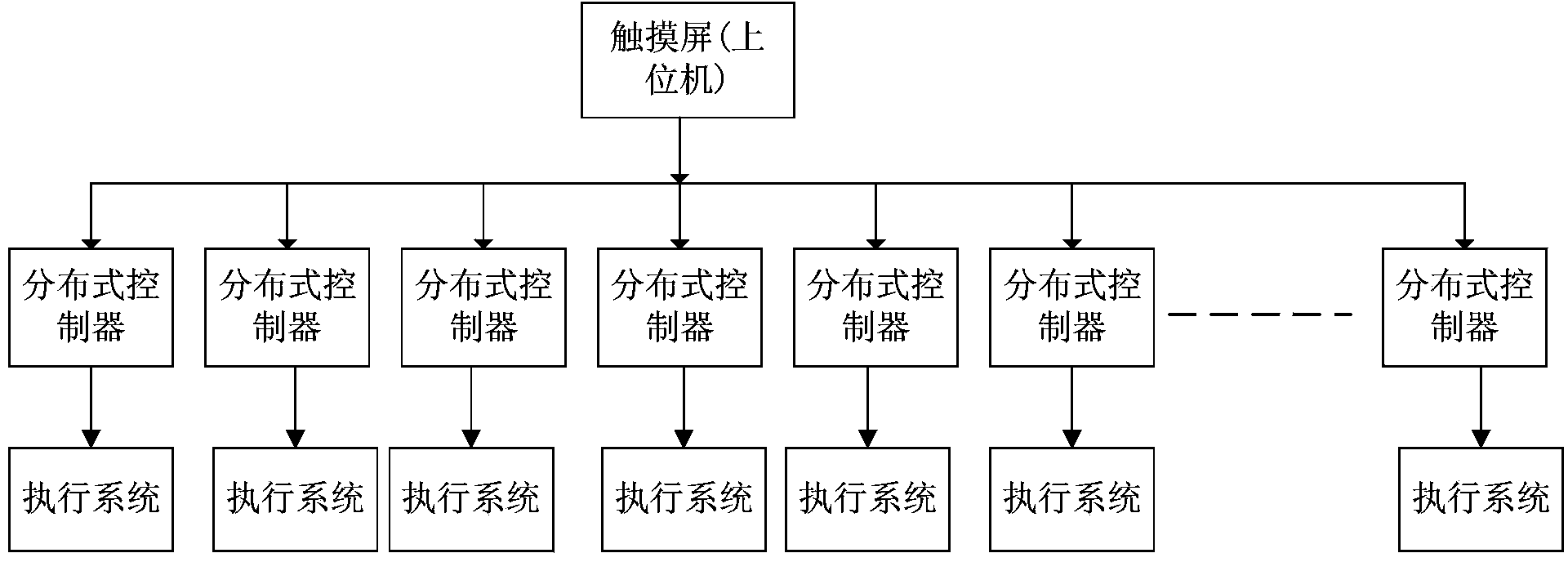

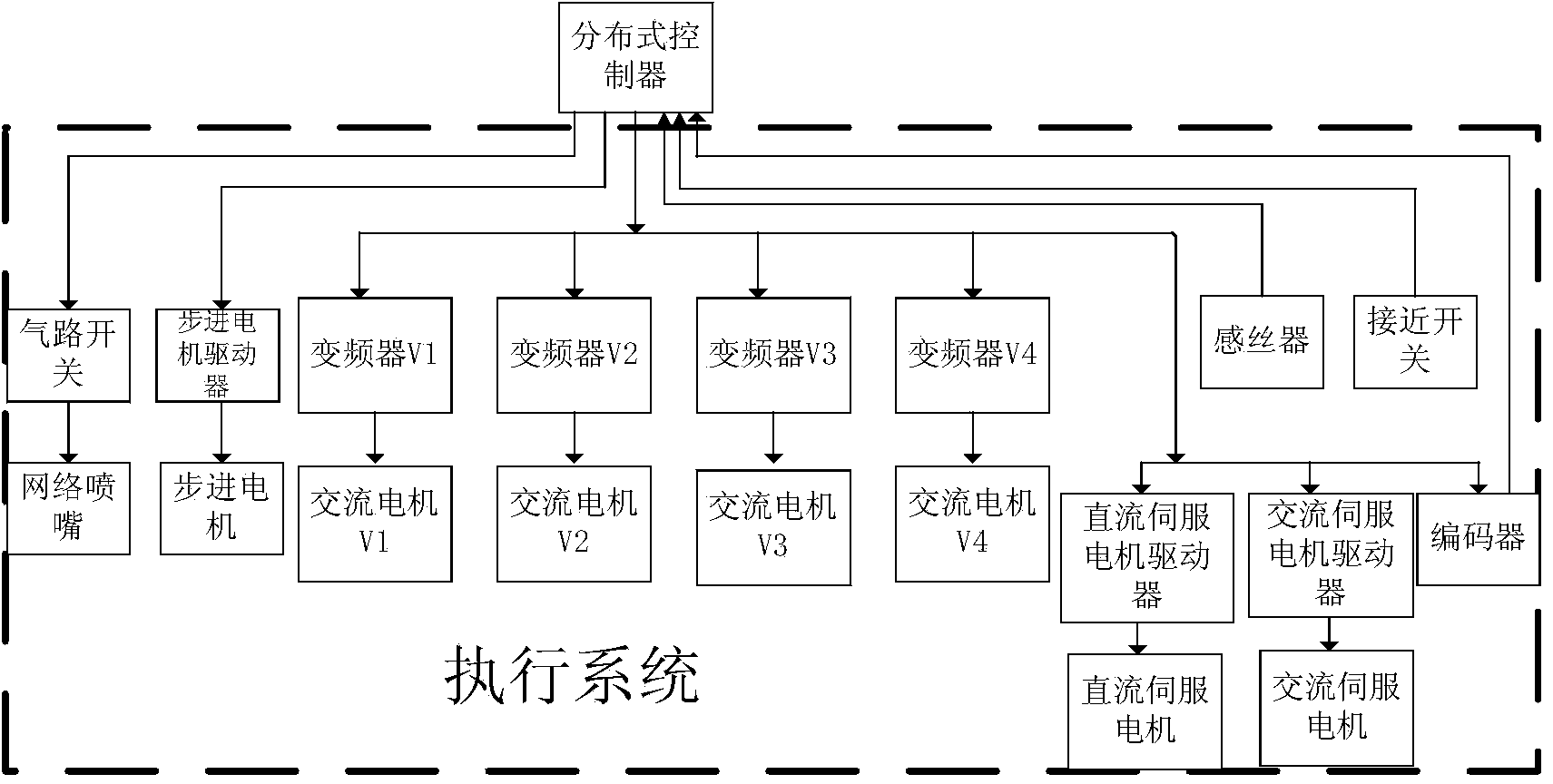

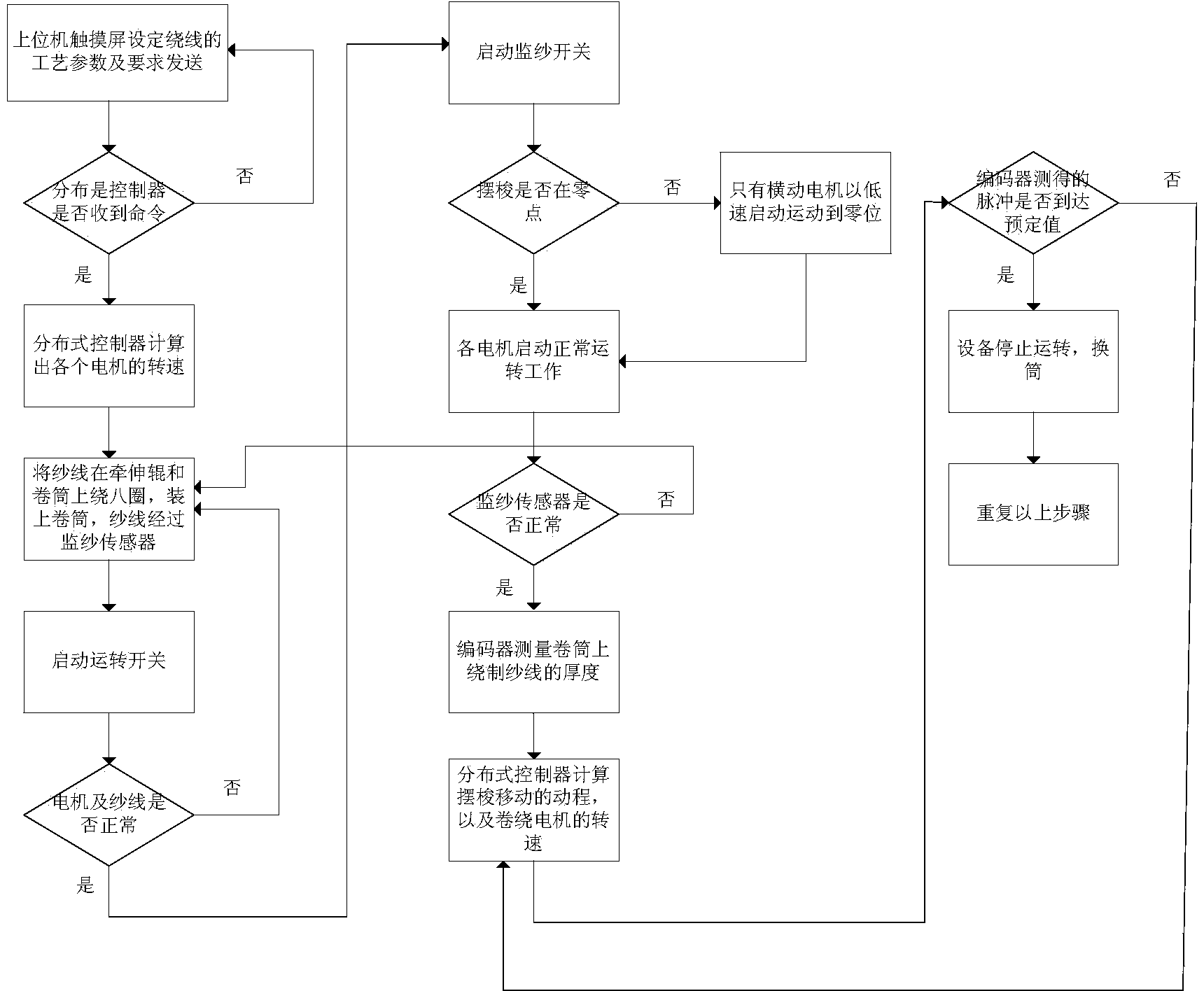

[0040] Such as figure 1 As shown, the single-spindle single-control control system of the air covering yarn machine includes a touch screen and a distributed controller. The touch screen is connected to 48 distributed controllers, and each distributed controller is connected to an executive system, such as figure 2 As shown, the execution system includes: four inverters: inverter V1, inverter V2, inverter V3, and inverter V4, four AC motors: AC motor V1, AC motor V2, AC motor V3, and AC motor V4 , A stepper motor driver, a stepper motor, an AC servo motor driver, an AC servo motor, a DC servo motor driver, a DC servo motor, a DC servo motor driver, two wire sensors, an encoder, three A proximity switch, a network nozzle and a gas circuit switch.

[0041] The touch screen is respectively connected with the distributed controller of each spindle. The distributed controller is respectively connected with four frequency converters, a stepping motor driver, an AC servo motor driver, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com