LED packaging substrate and LED packaging structure

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of uneven light color of the spot and achieve the effect of uniform light color of the spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

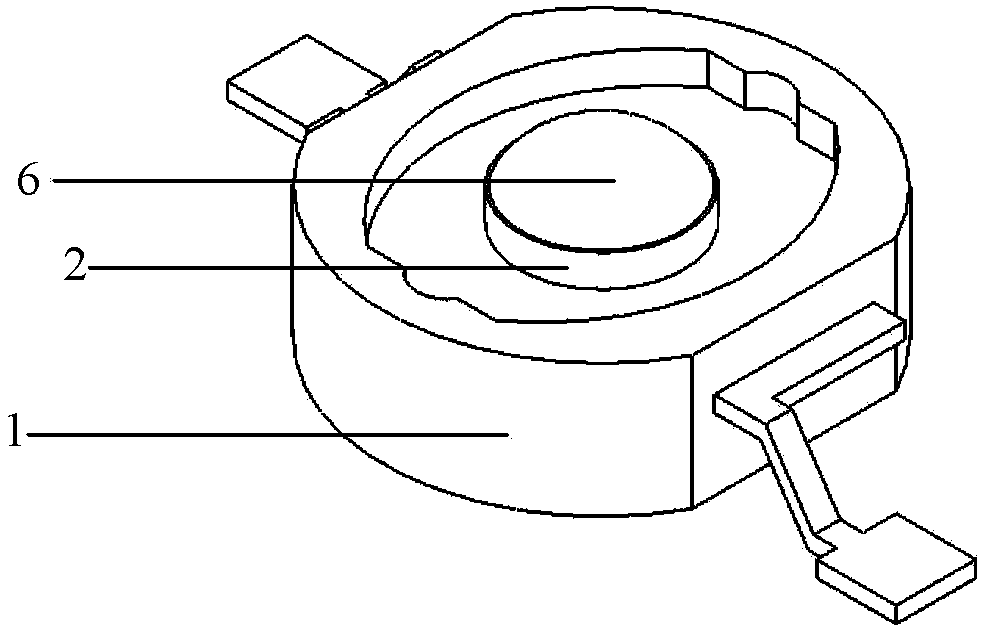

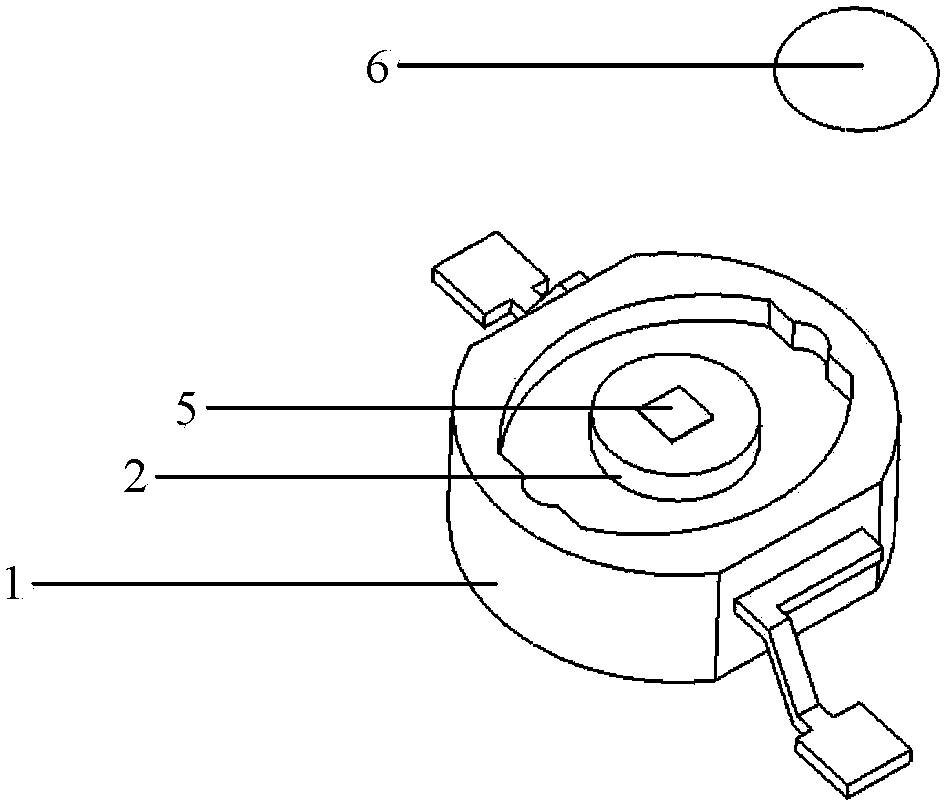

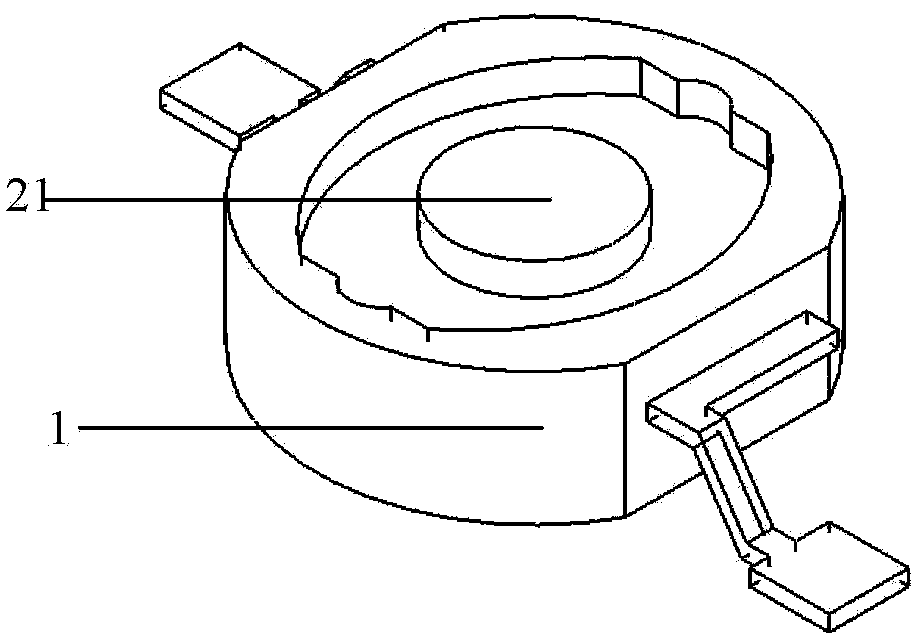

[0074] refer to Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 5 It is a three-dimensional schematic diagram of the LED packaging structure provided by Embodiment 1 of the present invention, Figure 6 It is an exploded view of the LED packaging structure provided by Embodiment 1 of the present invention, Figure 7 It is a three-dimensional schematic diagram of the LED packaging structure bracket body provided by Embodiment 1 of the present invention, Figure 8 It is a partially enlarged schematic diagram of the substrate in the LED packaging structure provided by Embodiment 1 of the present invention; it can be seen from the figure that the LED packaging structure provided by Embodiment 1 includes a bracket body 1, a substrate 2, an LED chip 5, and a fluorescent glue 6 There is a base 2 in the bracket body 1, the base 2 is made of metal (such as aluminum, copper) or ceramic material, the base 2 has a reflective structure 3 and a chip groove 4, the chip groove 4 i...

Embodiment 2

[0078] refer to Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 13 It is a three-dimensional schematic diagram of the LED packaging structure provided by Embodiment 2 of the present invention, Figure 14 It is an exploded view of the LED packaging structure provided by Embodiment 2 of the present invention, Figure 15 It is a three-dimensional schematic diagram of the bracket body of the LED packaging structure provided by Embodiment 2 of the present invention, Figure 16 It is a partially enlarged schematic diagram of the substrate in the LED packaging structure provided by Embodiment 2 of the present invention; it can be seen from the figure that the LED packaging structure provided by Embodiment 2 includes a bracket body 1, a substrate 2, an LED chip 5, and a fluorescent glue 6 There is a base 2 in the bracket body 1, the base 2 is made of metal (such as aluminum, copper) or ceramic material, the base 2 has a reflective structure 3 and a chip groove 4, the ...

Embodiment 3

[0082] refer to Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 20 It is a three-dimensional schematic diagram of the LED packaging structure provided by Embodiment 3 of the present invention, Figure 21 It is an exploded view of the LED packaging structure provided by Embodiment 3 of the present invention, Figure 22 It is a three-dimensional schematic diagram of the bracket body of the LED packaging structure provided by Embodiment 3 of the present invention, Figure 23 A partially enlarged schematic diagram of the substrate in the LED packaging structure provided by Embodiment 3 of the present invention; it can be seen from the figure that the LED packaging structure provided by Embodiment 3 includes a bracket body 1, a substrate 2, an LED chip 5, and a fluorescent glue 6 There is a base 2 in the bracket body 1, the base 2 is made of metal (such as aluminum, copper) or ceramic material, the base 2 has a reflective structure 3 and a chip groove 4, the chip g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap