Battery core folding equipment and battery core folding method adopting battery core folding equipment

A technology of folding equipment and battery cells, which is applied in the manufacture of non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, and electrolyte batteries, and can solve problems such as irregular wrinkles, liquid leakage, and obstacles to the wide application of arc-shaped soft-pack lithium batteries. , to achieve the effect of solving the problem of hemming leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The cell folding equipment and the cell folding method using it will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

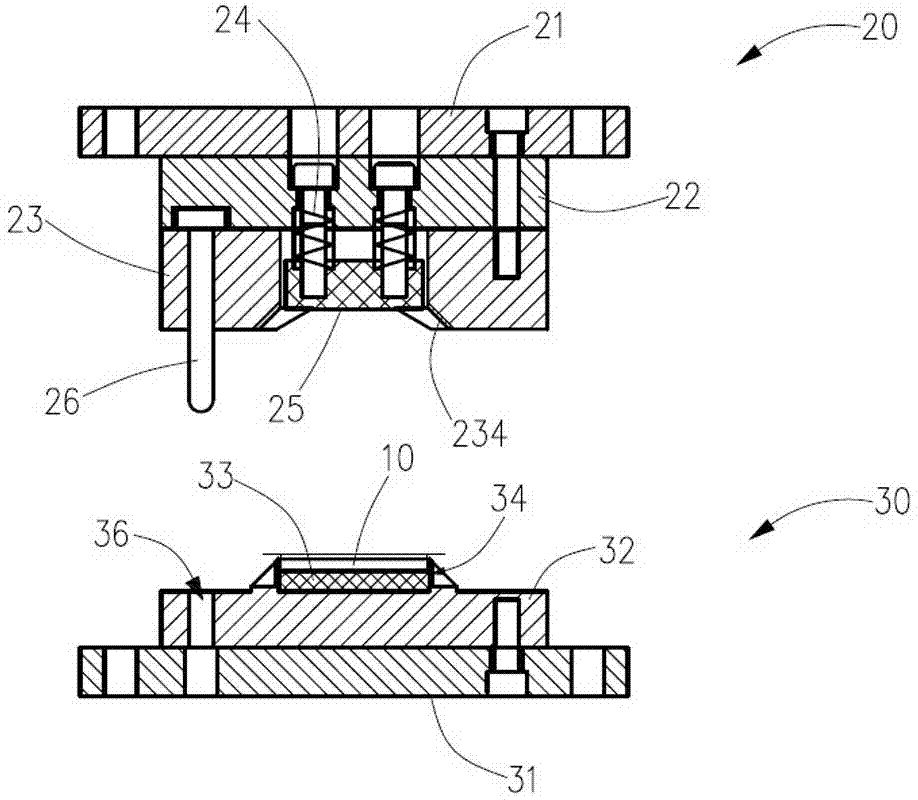

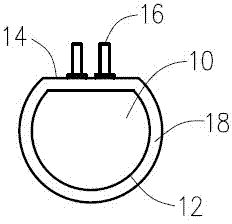

[0024] The electric core folding equipment of the present invention mainly includes a primary folding device and a secondary folding device, which are used for electric cells with arc-shaped edges, such as figure 2 After the shown unfolded cell 10 undergoes two folds, the folded folds at the arc edge of the cell are neat, and the bending angle relative to the outer wall of the cell is within an appropriate range.

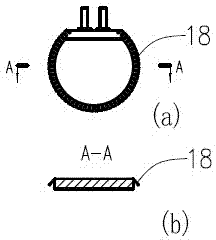

[0025] figure 2 The shape of the shown unfolded cell 10 is close to that of a table tennis racket, with a curved edge 12 and a straight edge 14 connecting the two ends of the curved edge, wherein the handle of the table tennis racket is replaced by the positive and negative tabs 16 of the battery. The packaging film has been heat-sealed and edge-sealed 18 extends from the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com