Composite contactor

A contactor and composite technology, used in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problem of high product price, and achieve the effect of prolonging contact life, reducing cost, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

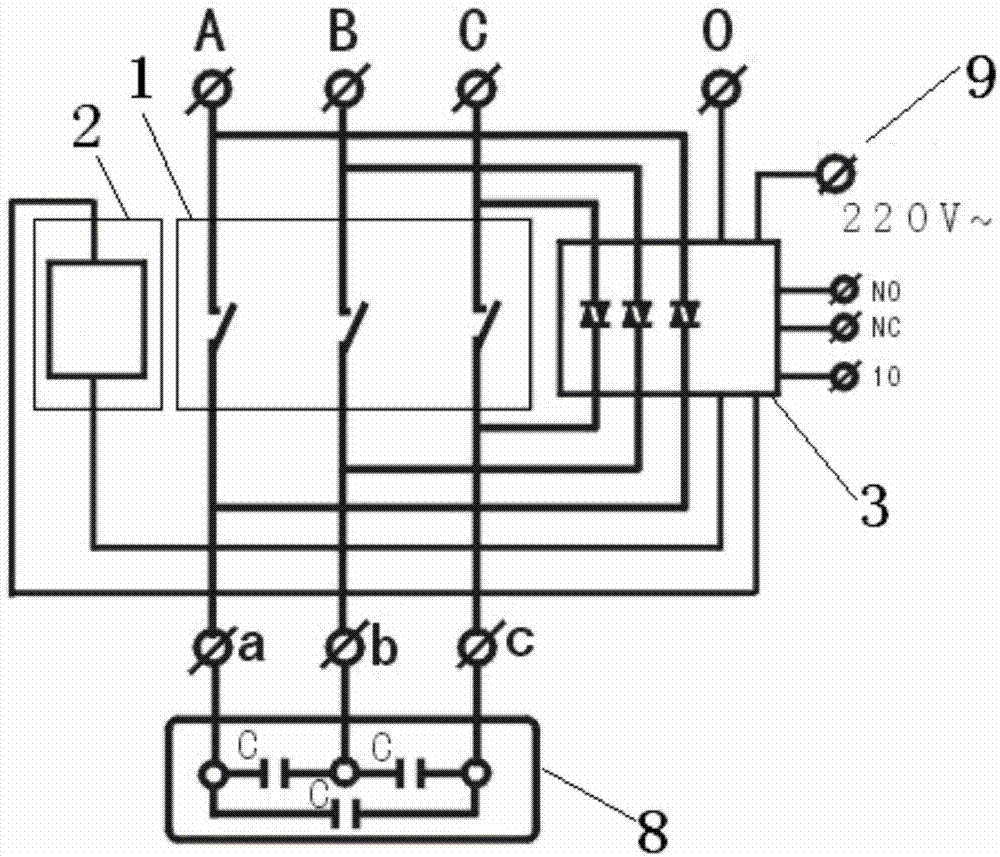

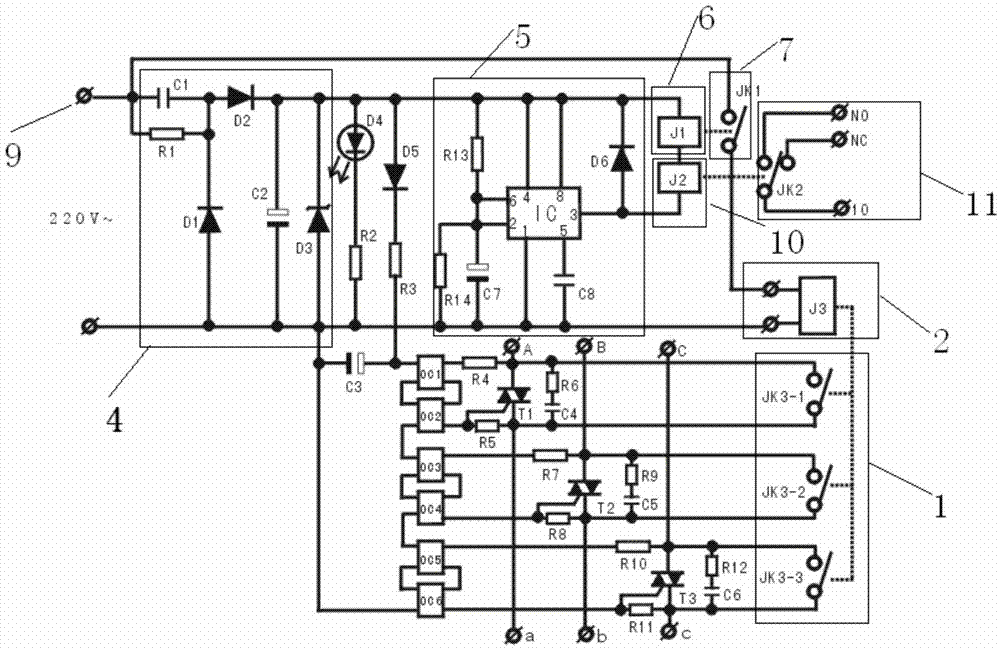

[0018] Such as Figure 1-2 As shown, a compound contactor described in the embodiment of the present invention includes three contactor switches 1 and contactor coil 1 2, and the A-phase power supply terminal, B-phase power supply terminal and C-phase power supply terminal respectively pass through the contactor Switch one 1 is connected with a terminal, b terminal and c terminal, and a line of control signal 9 power supply terminal is connected with the ground terminal through contactor coil one 2, and each contactor switch one 1 is connected in parallel with bidirectional thyristor 3, and the The other line of the power supply end of the control signal 9 is connected to a step-down circuit 4, and a line at the output end of the step-down circuit 4 is connected to C3 and optocouplers OC1-OC6 respectively through D5 and R3, and the optocoupler OC2, optocoupler OC4 and optocoupler OC6 is respectively connected with the control terminals of the bidirectional thyristor 3; another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com