Intelligent low-temperature vacuum fryer

A low-temperature vacuum frying and intelligent technology, applied in the direction of oil/fat baking, etc., can solve problems such as bad taste, fat thickening, affecting consumers' health, etc., achieve effective processing and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

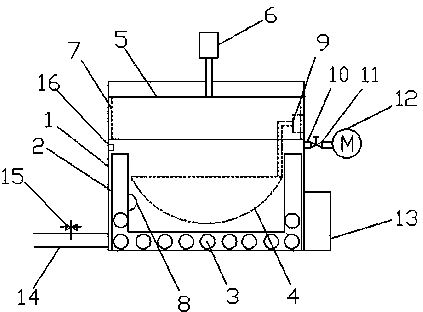

[0037] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

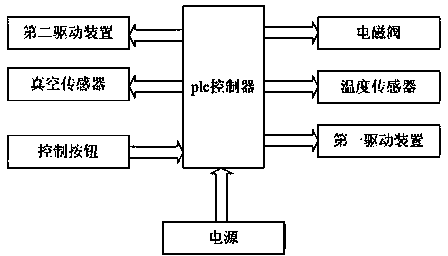

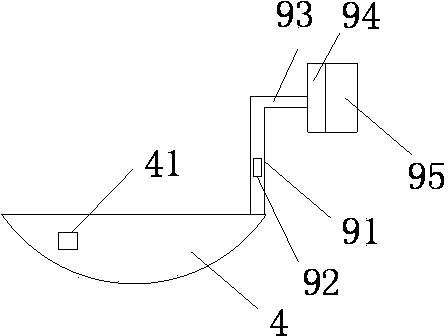

[0038] see figure 1As shown, it is a structural schematic diagram of a high-efficiency vacuum low-temperature fryer of the present invention, which includes a pot outer body 1, an inner pot 2 and a material pot 4, the pot outer body 1 is a sealed box, and the inner pot 2 is arranged on the pot Inside the outer body 1, the inner pot 2 is provided with a steam heating pipe 3, and one side of the outer body 1 of the pot is provided with a steam inlet pipe 14. There is a solenoid valve 15; the inner wall of the inner pot 2 is provided with a temperature sensor 8; the material pot 4 is arranged in the inner pot 2, and the said material pot is hole-shaped; the inner wall of the outer body 1 of the pot 4 on one side is provided with a first Driving device 9, the first driving device 9 is connected to one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com