Curved surface object corner recognizing and spraying method

A technology of horns and objects, applied in spraying devices, special data processing applications, instruments, etc., can solve problems such as not being able to improve spraying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

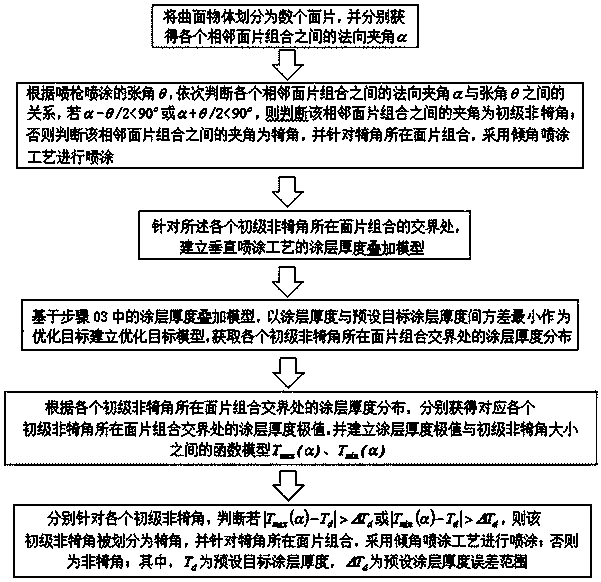

[0058] Such as figure 1 As shown, the present invention has designed the present invention to design a kind of curved surface object horn recognition spraying method in concrete practical application, comprises the following steps:

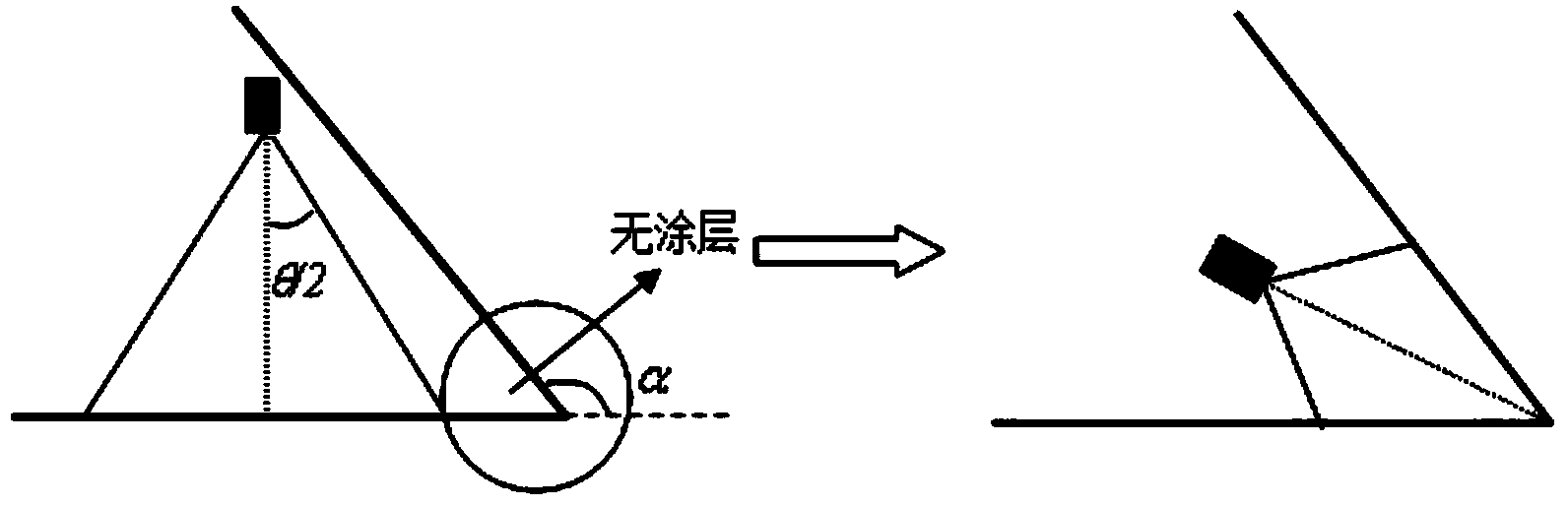

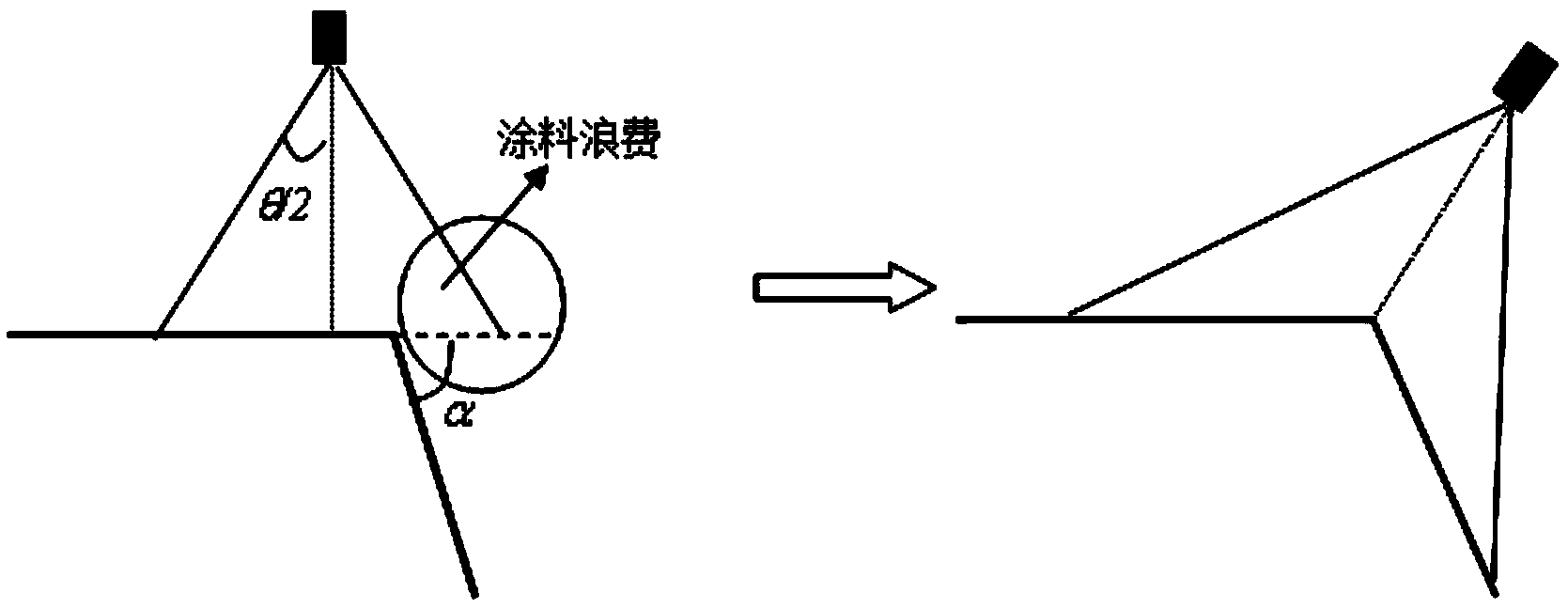

[0059] Step 01. Use the triangular meshing method and the geometric topology method to divide the surface object into several patches, and obtain the normal angle α between each adjacent patch combination, specifically including the following steps:

[0060] Step 0101. Carry out triangular meshing for complex free-form surfaces, assuming that after the vertical spraying trajectory of the spray gun for each triangular surface is optimized, the maximum coating thickness, average coating thickness and minimum coating thickness on each triangular surface are T ' max , T' d and T' min , the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com