Automatic water meter cover machine

A water meter, automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, large water meter error, and water meter leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

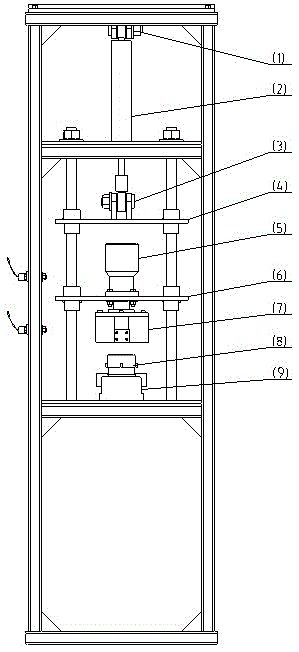

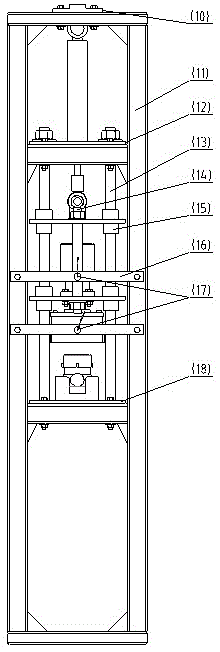

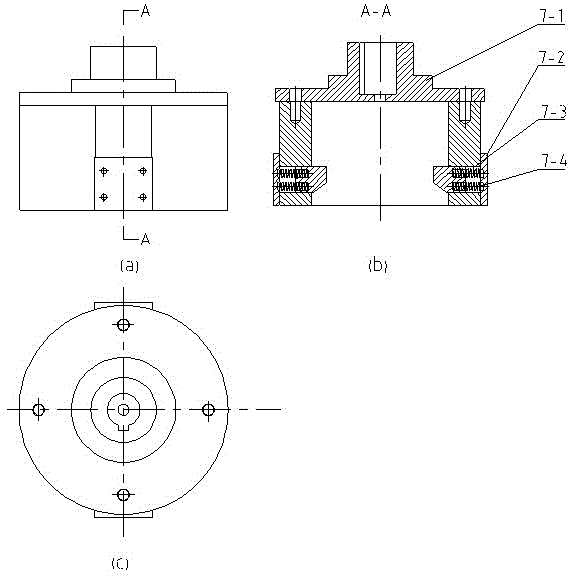

[0021] see Figure 1~Figure 5 , the automatic water meter cover machine includes a frame (11), an earring-connected hydraulic cylinder (2) is installed on the top of the frame (11), and a hydraulic cylinder support plate (10) is connected to the frame ( 11), the upper and lower ends of the hydraulic cylinder (2) are respectively hinged through the upper pin (1) and a lower pin (3) and the hydraulic cylinder support plate (10) and an upper lifting support plate (4), and an upper The guide post support plate (12) and a lower guide post support plate (18) are connected to the frame (11) by bolts, and the two ends of the four guide posts (13) are respectively connected to the upper guide post support plate (12) by bolts. ) and the lower guide column support plate (18); the output shaft of a hydraulic motor (5) is connected to the water meter cover chuck (7) through bolts and flat keys, and the housing of the hydraulic motor (5) is connected to a lower lifting support through bolts...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0024] In the automatic water meter capping machine, the upper and lower ends of the earring-connected hydraulic cylinder (2) are respectively hinged with the hydraulic cylinder support plate (10) and the upper lift support plate (4) through bolts, and the expansion and contraction of the piston rod of the hydraulic cylinder (2) The motion drives the upper and lower lifting support plates (4, 6) to do the lifting motion.

[0025] In the automatic water meter cover machine, the guide columns (13) are respectively fixed on the upper and lower guide column support plates (12, 18) by means of bolt connection, and the upper and lower lift support plates (4, 6) pass through the guide sleeves (15 ) and the guide column (13) form a moving pair, which performs lifting motion under the action of the hydraulic cylinder (2).

[0026] In the automatic water meter cover machine, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com