Suspension descending system

A suspension and side plate technology, applied in portable lifting devices, building structure support, applications, etc., can solve the problems of troublesome construction and operation, unable to lift the rope, and great effort, and achieve convenient construction and operation, automatic Lower effort saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

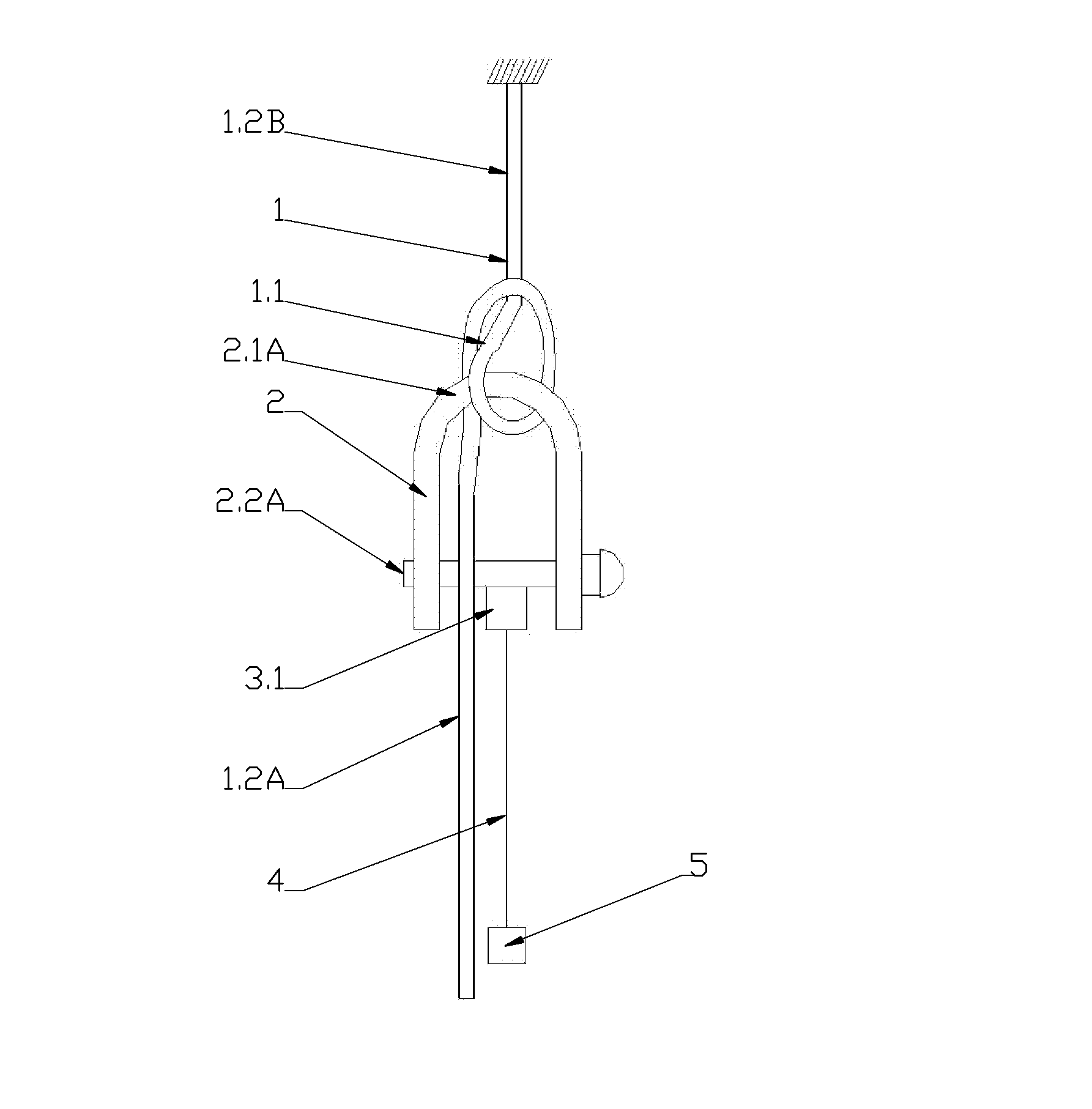

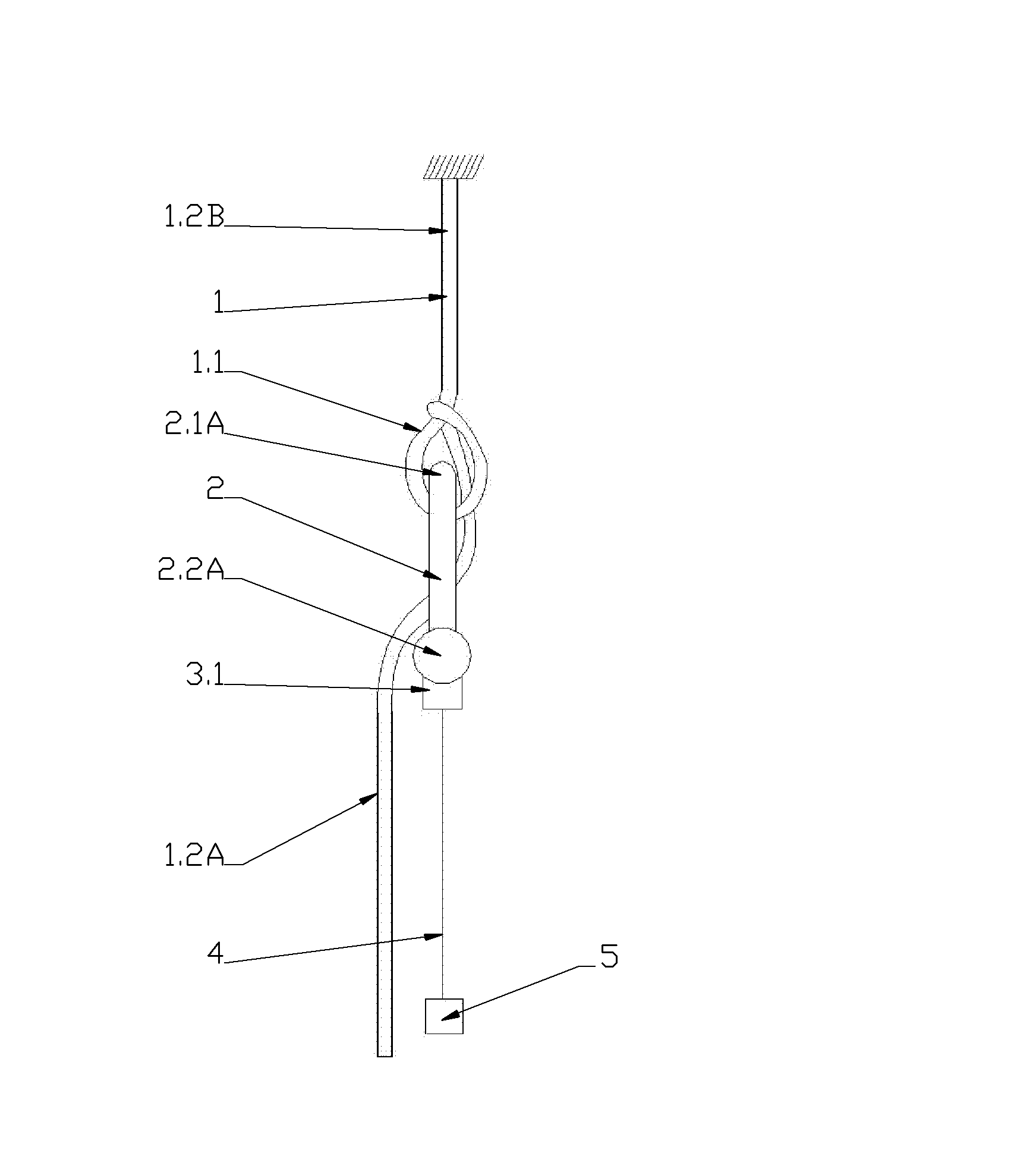

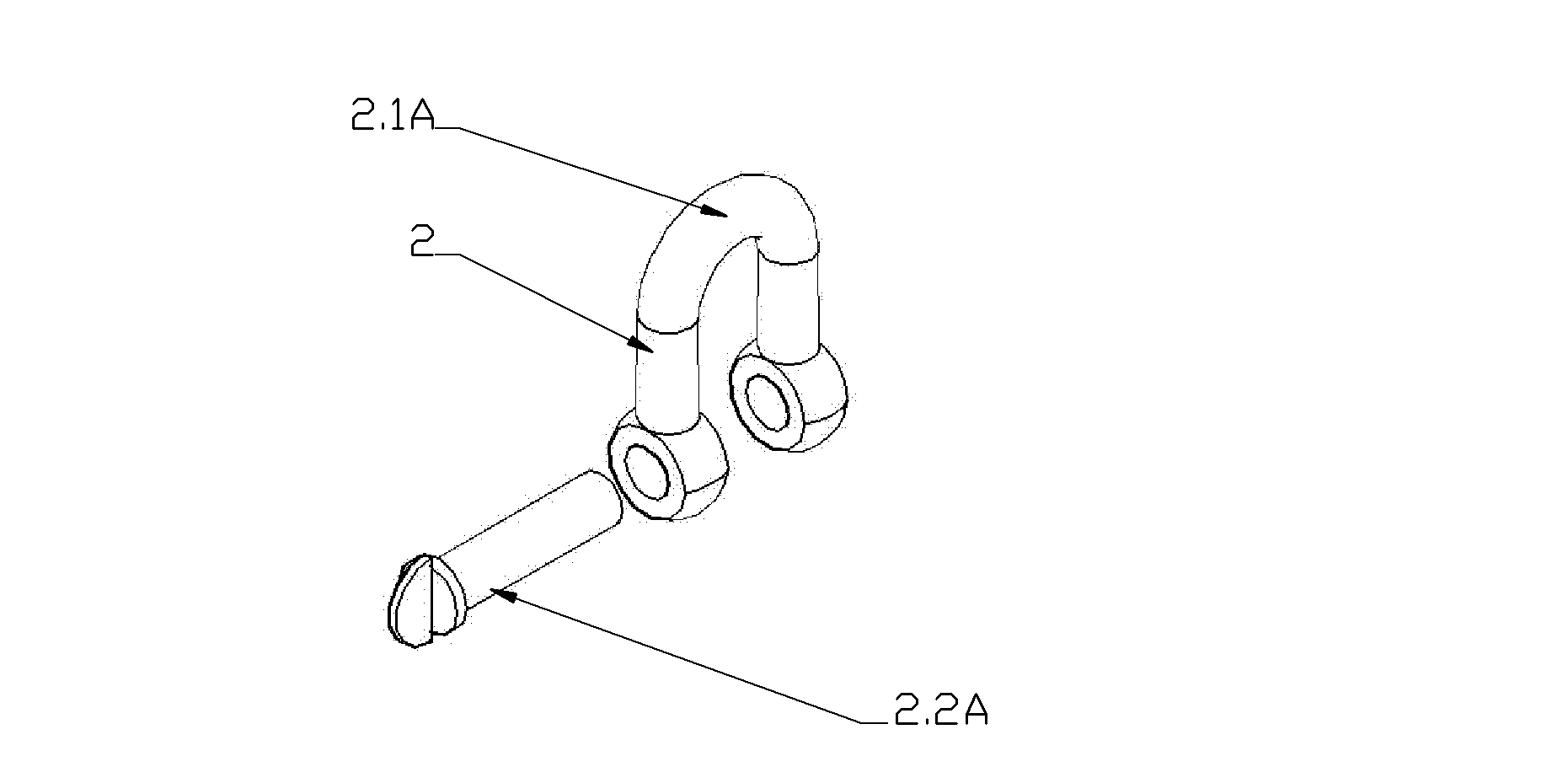

[0024] figure 1 , figure 2 , image 3 , Figure 4 It is a structural schematic diagram of an embodiment of the prior art; wherein figure 1 main view, figure 2 for the left view, image 3 , Figure 4 is a local schematic. figure 1 , figure 2shows that in the prior art, the seat plate type single-person spreader mainly includes a working rope 1, a descender 2, a connector 3.1, and a loading device 4; when in use, the working rope 1 is fixed on the fixed end 1.2B. At a high place, the working rope 1 is tied with a special knot 1.1 on the descender 2, and then bypasses the first passing shaft 2.2A, and the human body 5 is fixed on the passing shaft 2.2 of the descending device 2 through the loading device 4 and the connector 3.1 on A. Because special knot 1.1 is arranged, human body 5 can not slide down, but can realize free descent by operating work rope 1. When it is necessary to descend, the operator only needs to lift up the free end rope 1.2A (the end of the rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com