Transverse shear-resistant reinforcing steel bar connecting device for concrete bridge deck slabs

A technology for lateral connection and shearing steel bars, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem of insufficient space for the arrangement of steel bars, and achieve the effect of convenient installation and accurate stress state of hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

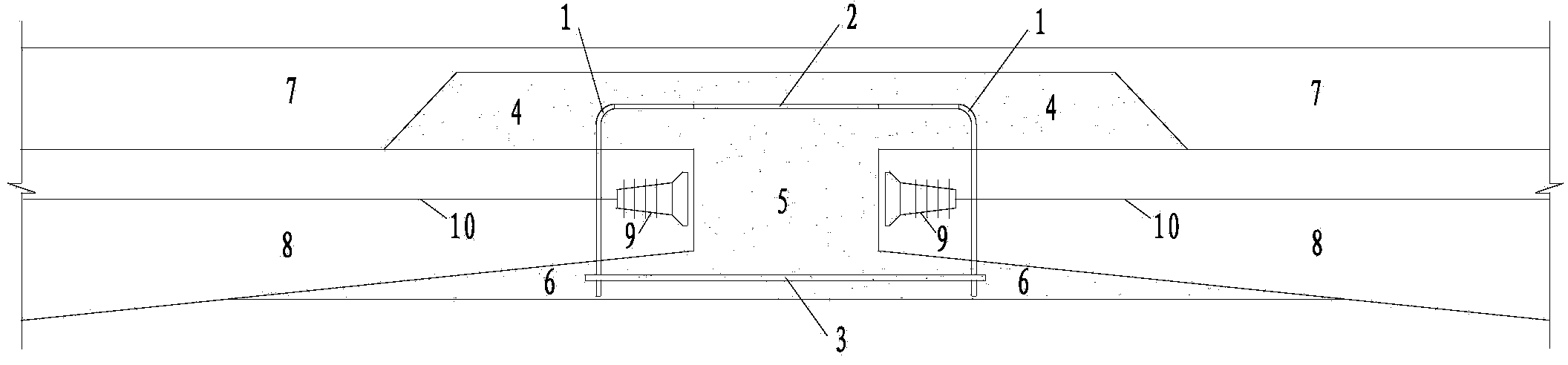

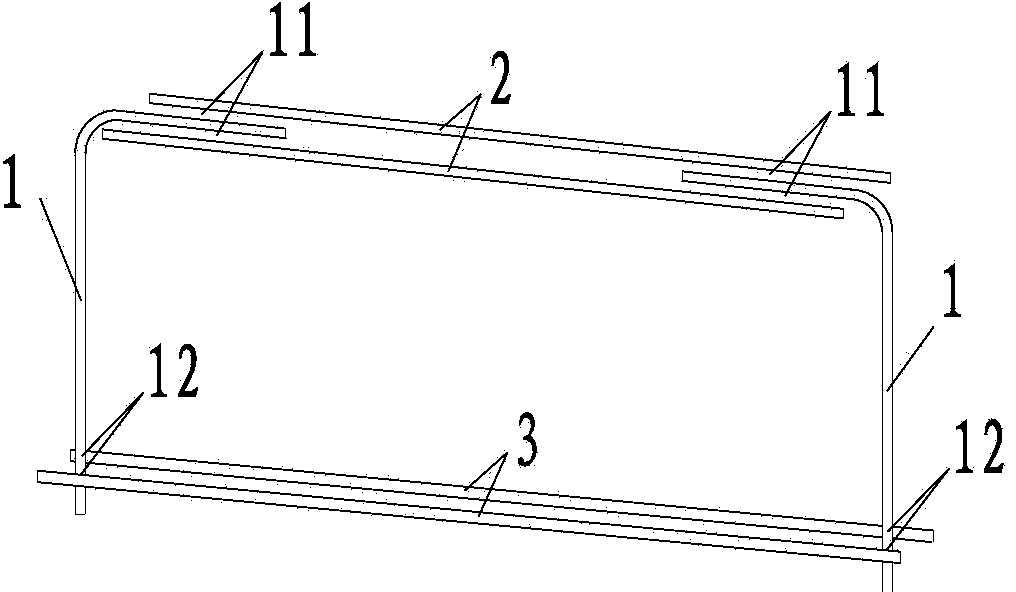

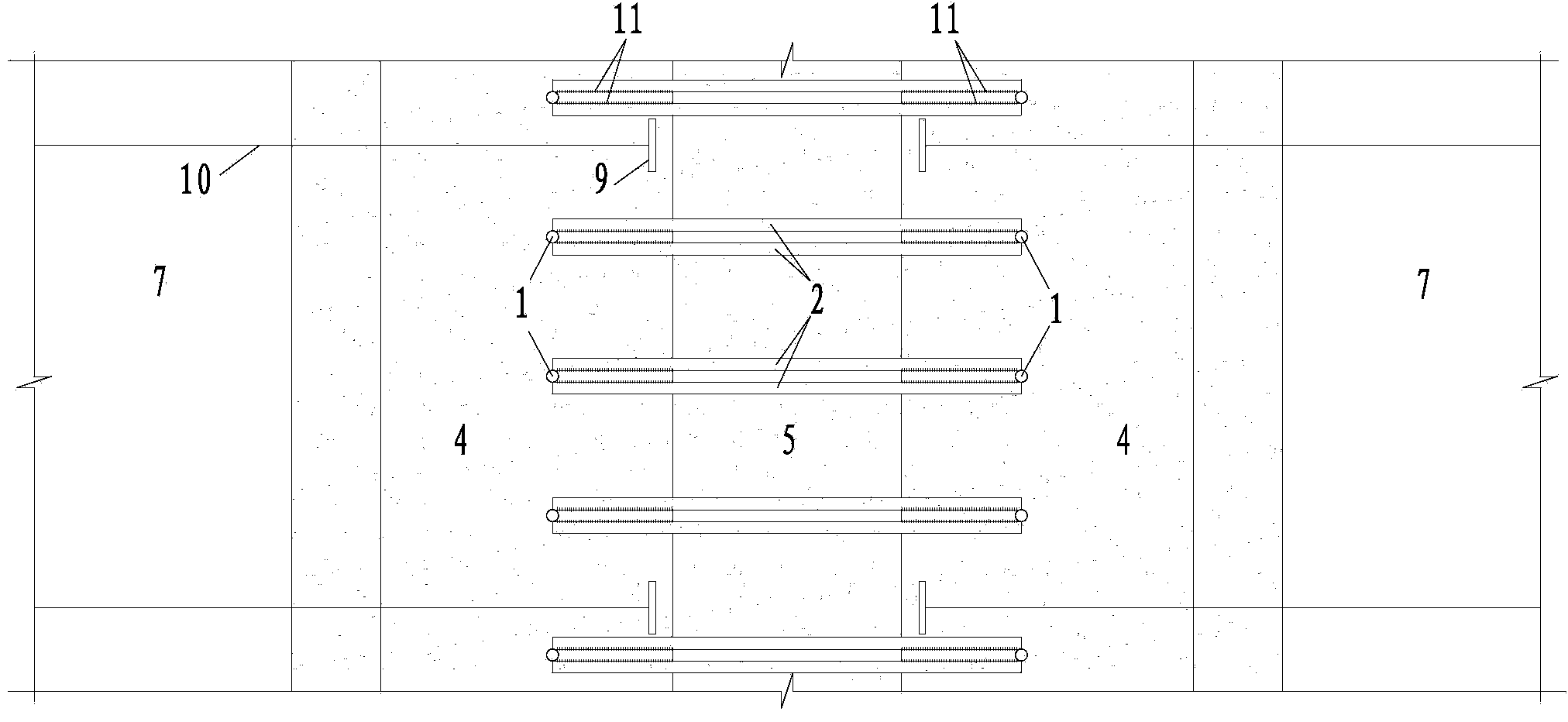

[0031] Such as Figure 1 to Figure 5 As shown, a concrete bridge deck transverse shear reinforcement connection device includes sets of steel bars distributed at intervals of 15 cm along the longitudinal direction of the bridge. Steel bars 3 form a rectangular frame structure;

[0032]The diameter of the vertical steel bar 1 is 18cm, including a vertical main bar and a transverse bend, the transverse bend is arranged on the upper end of the vertical main bar, and the two vertical bars 1 are symmetrical to the two transverse bars to be connected The axis of symmetry of the concrete bridge deck 8 and the vertical main bars are respectively inserted up and down in the two concrete bridge decks 8. The concrete bridge deck 8 can be either a cast-in-place bridge deck or a prefabricated bridge deck. Just expose the top surfaces of the two concrete bridge decks 8 to be conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com