Passive up hole grouting hole sealing and check plug and grouting hole sealing method

A passive, hole-moving technology, which is applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve problems such as hole sealing failure, orifice sealing failure, and large cork gaps, so as to avoid construction The effect of slow progress and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention is described in further detail:

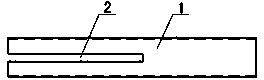

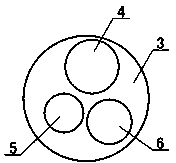

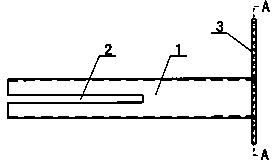

[0046] like Figure 1-Figure 4 As shown, the passive upward hole grouting sealing hole check plug of the present invention includes a connecting steel pipe 1 and a circular steel plate 3, and the connecting steel pipe 1 is used to pass through the piezometric tube (see Figure 5 The piezometric tube 8) is connected with the piezometric tube, the circular steel plate 3 is used to block the upward hole, and the circular steel plate 3 is provided with three through holes, and the three through holes are respectively used Grouting pipes for grouting in holes (see Figure 5 The grouting through-hole 4 of the grouting pipe 14) in the grouting pipe is used to pass through the grouting pipe returning to the grout in the ascending hole (see Figure 5 The grouting through hole 6 of the grouting pipe 15) and the connecting through hole 5 communicating with the connecting steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com