Out-of-gear-preventive synchronizer gear sleeve

A technology of synchronizer and tooth sleeve, which is applied in the field of automotive synchronizer structure, which can solve the problems of affecting vehicle driving safety, gear shift sticking, labor, etc., to improve work efficiency, increase the moving gap, and reduce the cumulative error of the pitch bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

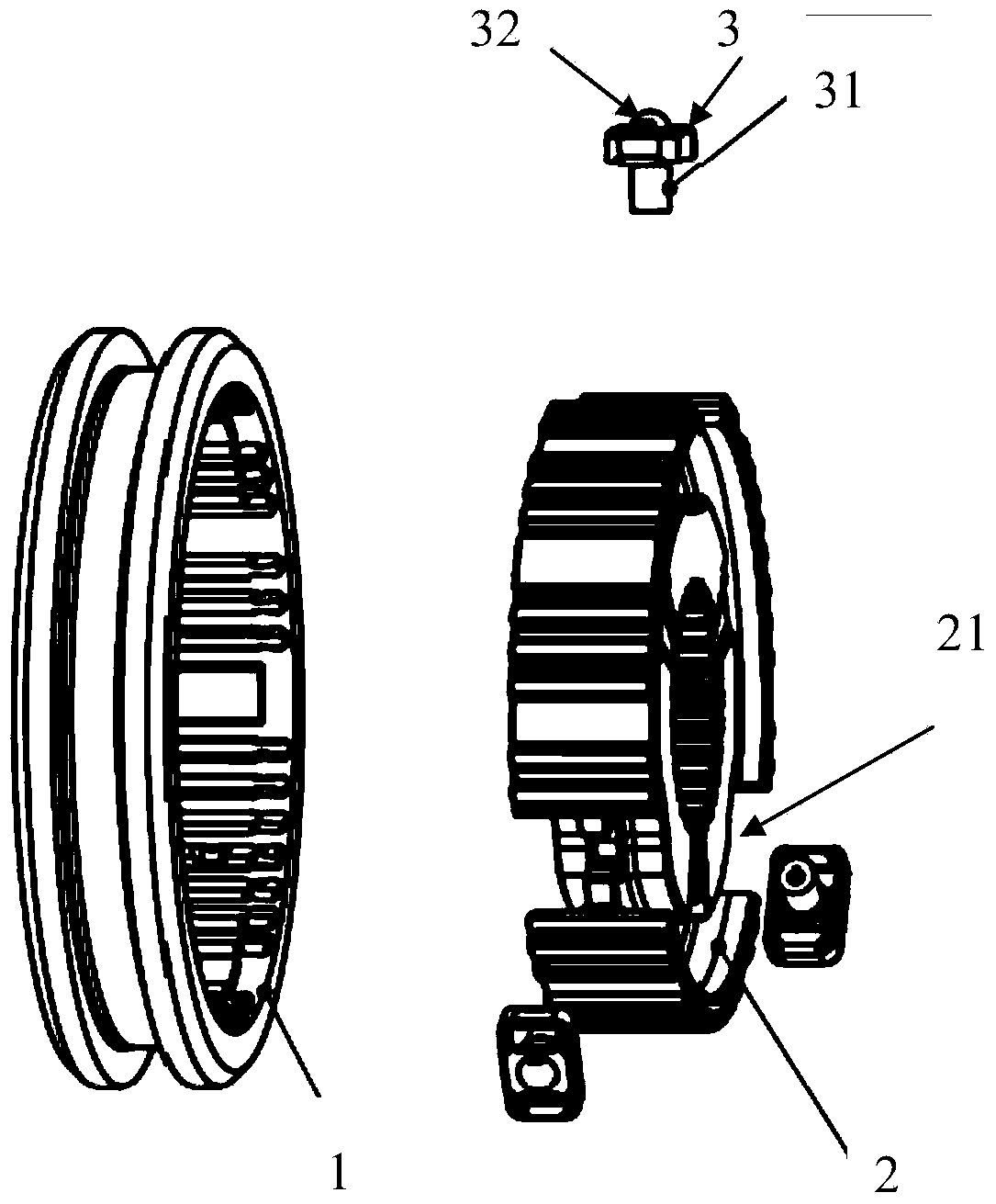

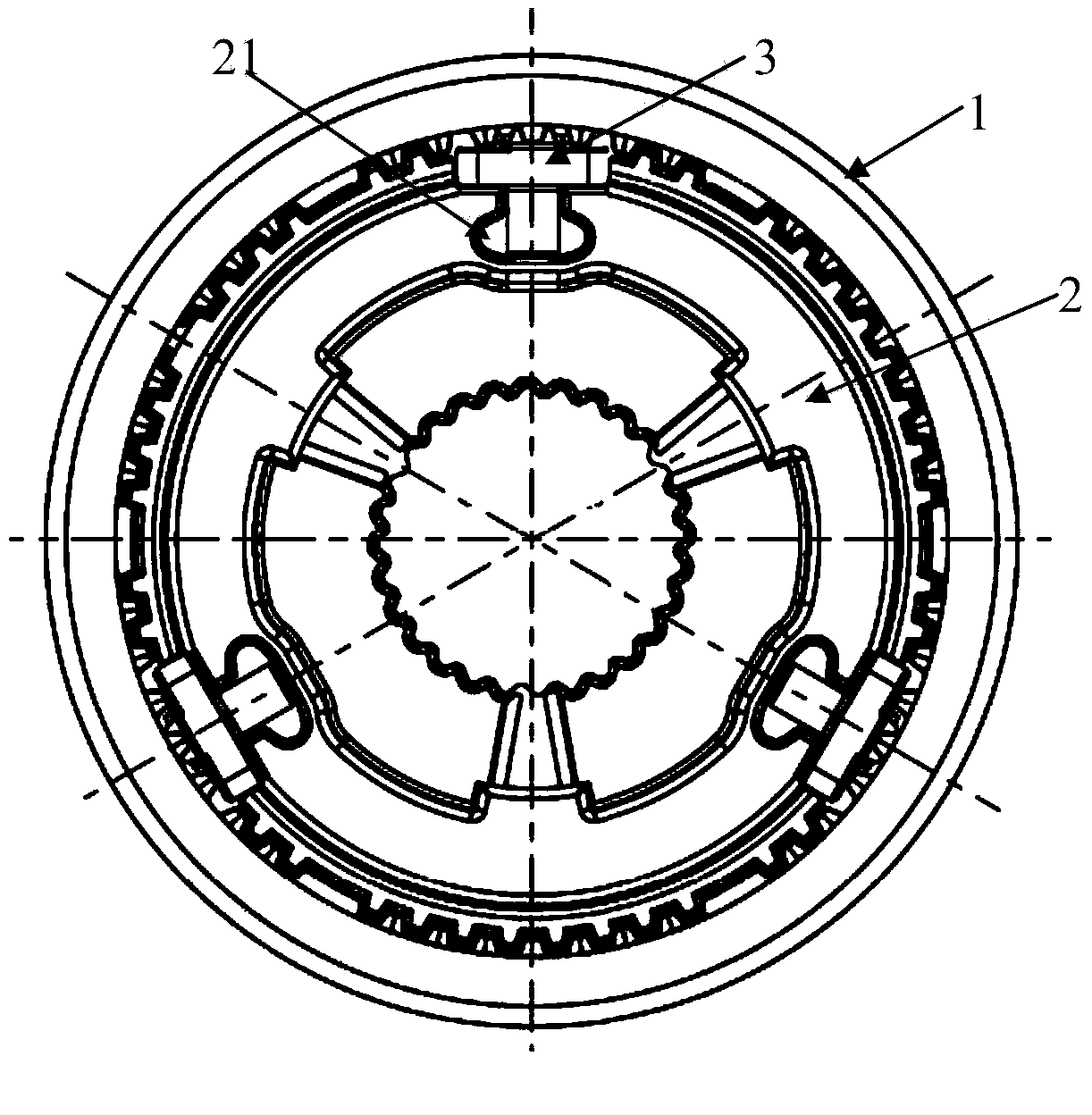

[0014] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

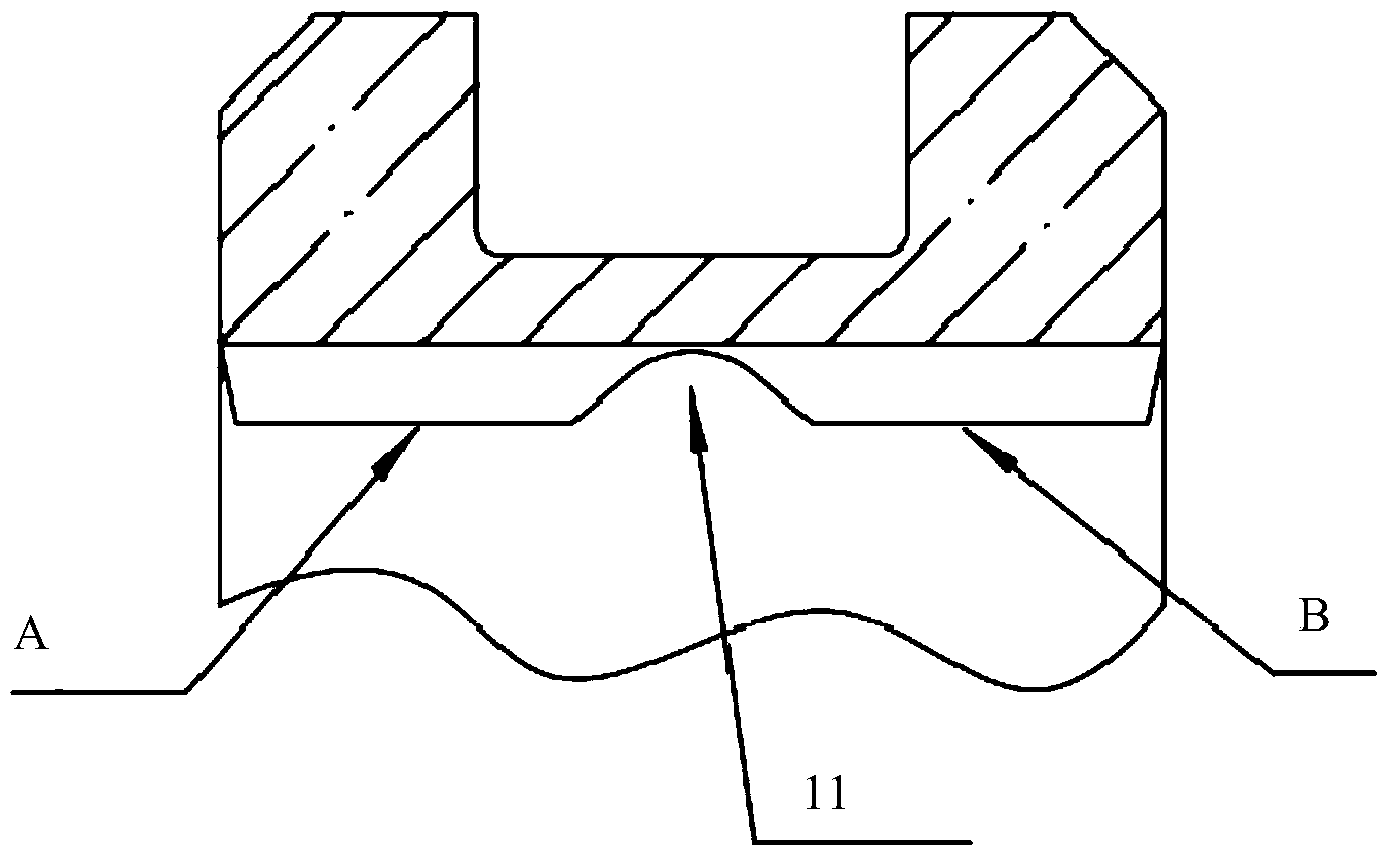

[0015] Such as Figure 4 As shown, a positioning groove 11 is provided on the spline tooth corresponding to the positioning protrusion 32 of the gear sleeve 1 and the slider. . When in neutral position, the positioning groove 11 in the middle position of the gear sleeve contacts with the top of the positioning protrusion 32 of the slider, and the elastic force provided by the spring of the slider ensures that the gear sleeve is in the neutral position; when the synchronizer shifts gears, The gear sleeve will move axially under the force of the shift fork. When the gear sleeve moves to the specified position, the limit groove 12 on the spline teeth of the gear sleeve just contacts the positioning protrusion 32 of the slider, and the replacement is completed. At the same time, the limit groove 12 and the positioning protrusion 32 play the role of limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com