LED uniform-collimation optical system

An optical system and uniform technology, applied in the field of collimating optical systems, can solve the problems of insufficient light efficiency of the lens, inability to collect all the light of the LED, affecting the propagation distance of the system, etc., and achieve the effect of good light control ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

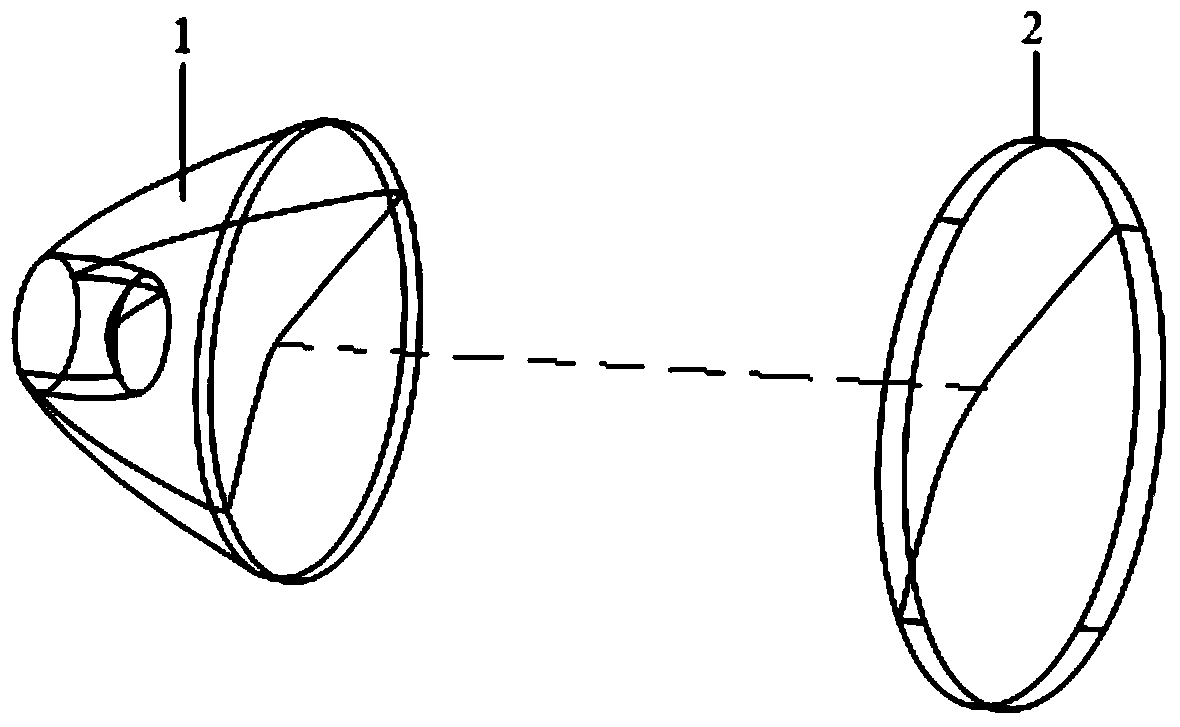

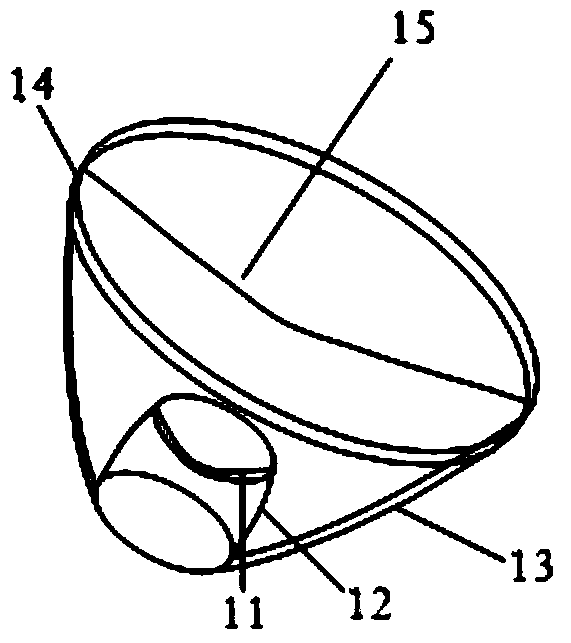

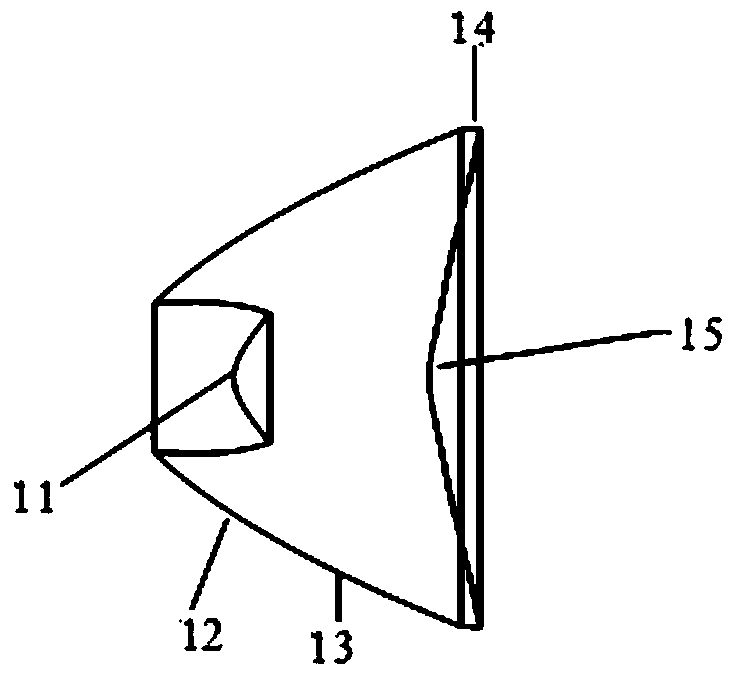

[0024] Figure 1-4 The optical system for LED uniform collimation shown in , includes a first free-form surface lens 1 and a second free-form surface lens 2 coaxially arranged, and the distance between the first free-form surface lens 1 and the second free-form surface lens 2 is 0.01m-0.1 m; the first free-form surface lens 1 includes a first curved surface 11, which is a rotationally symmetrical free-form surface for refracting the light emitted by the LED so that the refracted light is parallel to the z-axis, and the LED light controlled by the free-form surface is aligned with the z-axis The included angle is determined by the refractive index of the lens material; the second curved surface 12 is a rotationally symmetrical free-form surface, which is used to refract the light emitted by the LED so that the refracted light coincides with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com