Electromechanical hydraulic control united simulation method

A co-simulation, electromechanical-hydraulic technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as low efficiency, high cost, and inability to meet the rapidity and diversity requirements of modern design, and achieve credible high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

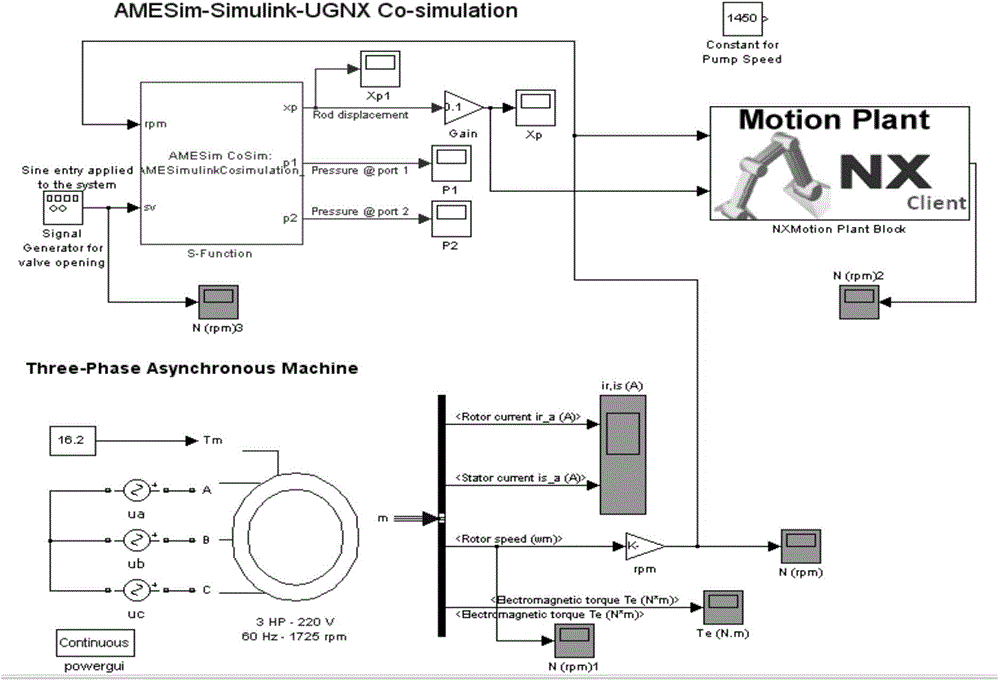

[0009] The electromechanical-hydraulic control co-simulation method provided by the present invention designs the mechanical part of the electromechanical product under UGNX, designs the electrical part under Matlab / Simulink, simulates the hydraulic system under AMESim, and transmits the control information to UGNX and AMESim respectively by Simulink, Then the three perform joint simulation to analyze the dynamic characteristics of electromechanical products.

[0010] Such as figure 1 As shown, the three-phase asynchronous AC motor in Simulink transmits the speed information and servo valve control information to AMESim, and transmits the speed information to UGNX, and AMESim transmits the displacement information of the hydraulic push rod to UGNX.

[0011] The specific steps of the design under UGNX are that UGNX adopts version 8.0,

[0012] 1) Start UGNX, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com