Iron-gallium alloy converse magnetostriction actuator driven by rotating motor and using method

A technology of inverse magnetostriction and rotating motors, applied in the direction of piezoelectric effect/electrostriction or magnetostriction motors, generators/motors, electrical components, etc., can solve the problem of low magnetic permeability of magnetostrictive materials and current Problems such as heat loss and high temperature have been solved to meet the needs of high-precision positioning and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

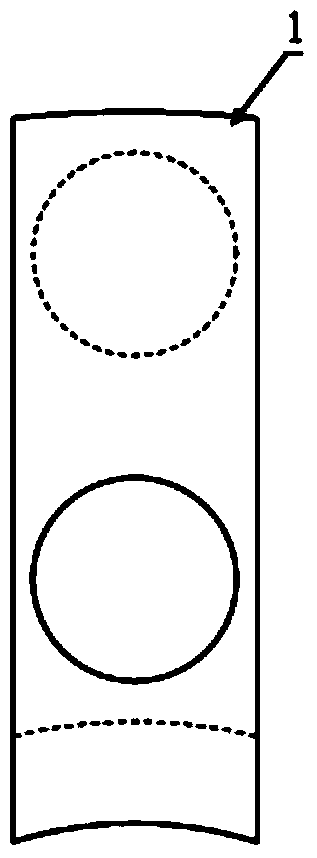

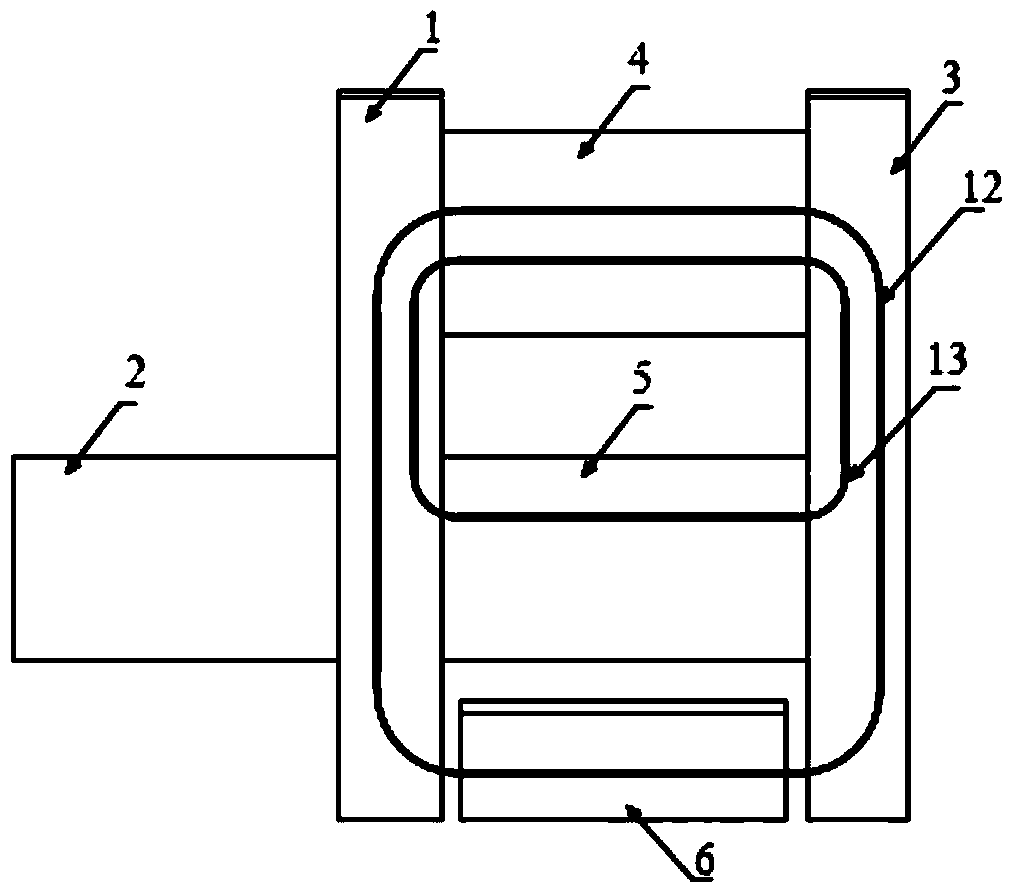

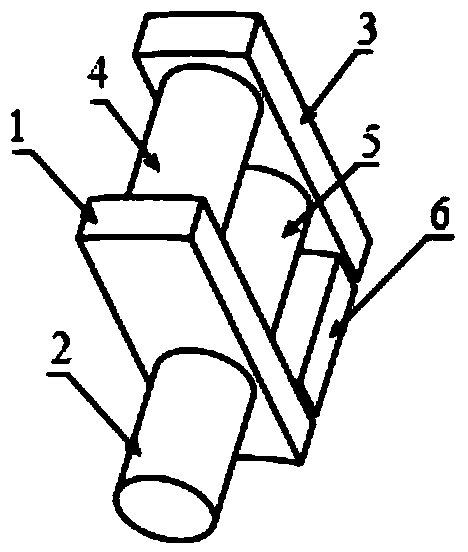

[0020] Embodiment 1, Figure 1 to Figure 7 An iron-gallium alloy inverse magnetostrictive driver driven by a rotating motor is given, including a rotating motor and an iron-gallium alloy inverse magnetostrictive driver; the iron-gallium alloy inverse magnetostrictive driver includes an upper conductive core 1 and a lower conductive core 3 and mover iron core 6; there is a gap between the upper magnetic core 1 and the lower magnetic core 3, and permanent magnets 4 parallel to each other are arranged in the gap between the upper magnetic core 1 and the lower magnetic core 3 (the magnetization direction of the permanent magnet 4 is the axial direction) and the iron-gallium alloy 5, the gap on one side of the iron-gallium alloy 5 is set as the mover gap, and the mover iron gap matching with the mover gap is arranged in the mover gap. Core 6; a circular fixed block 11 is arranged on the output shaft of the rotating motor, and the mover iron core 6 is fixed on the edge of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com